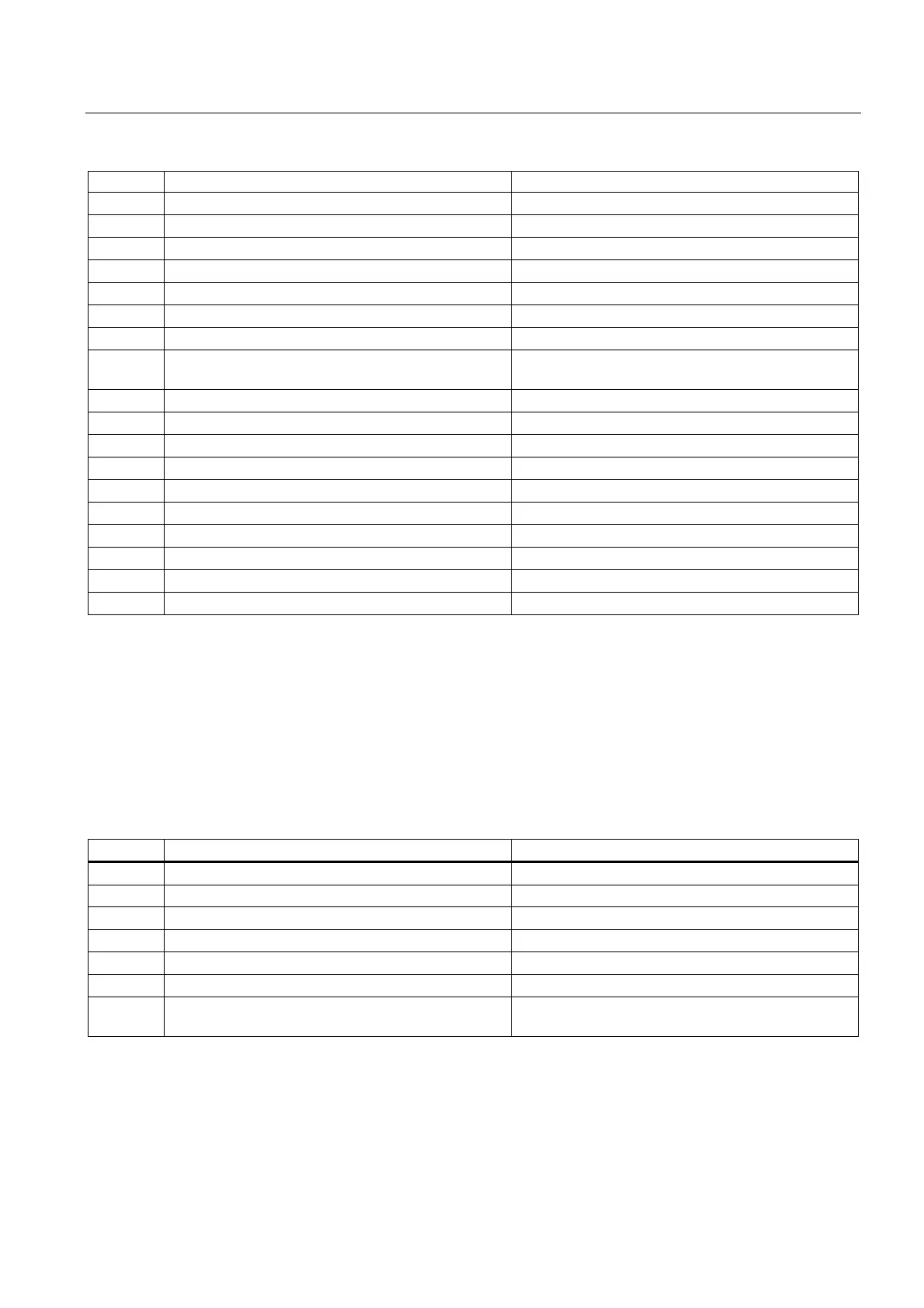

Data Lists

5.2 Setting data

Spindles (S1)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

5-3

Number Identifier: $MA_ Description

35150 SPIND_DES_VELO_TOL Spindle speed tolerance

35160 SPIND_EXTERN_VELO_LIMIT Spindle speed limitation via PLC

35200 GEAR_STEP_SPEEDCTRL_ACCEL[n] Acceleration in speed control mode

35210 GEAR_STEP_POSCTRL_ACCEL[n] Acceleration in position control mode

35220 ACCEL_REDUCTION_SPEED_POINT Speed limit for reduced acceleration

35230 ACCEL_REDUCTION_FACTOR Reduced acceleration

35300 SPIND_POSCTRL_VELO position control activation speed

35350 SPIND_POSITIONING_DIR Positioning direction of rotation for a non-

synchronized spindle

35400 SPIND_OSCILL_DES_VELO Oscillation speed

35410 SPIND_OSCILL_ACCEL Oscillation acceleration

35430 SPIND_OSCILL_START_DIR Oscillation start direction

35440 SPIND_OSCILL_TIME_CW Oscillation time for M3 direction

35450 SPIND_OSCILL_TIME_CCW Oscillation time for M4 direction

35500 SPIND_ON_SPEED_AT_IPO_START Feed enable with spindle in setpoint range

35510 SPIND_STOPPED_AT_IPO_START Feed enable with stationary spindle

35590 PARAMSET_CHANGE_ENABLE Parameter set definition possible from PLC

36060 STANDSTILL_VELO_TOL Threshold velocity "Axis/spindle stationary"

36200 AX_VELO_LIMIT Threshold value for velocity monitoring.

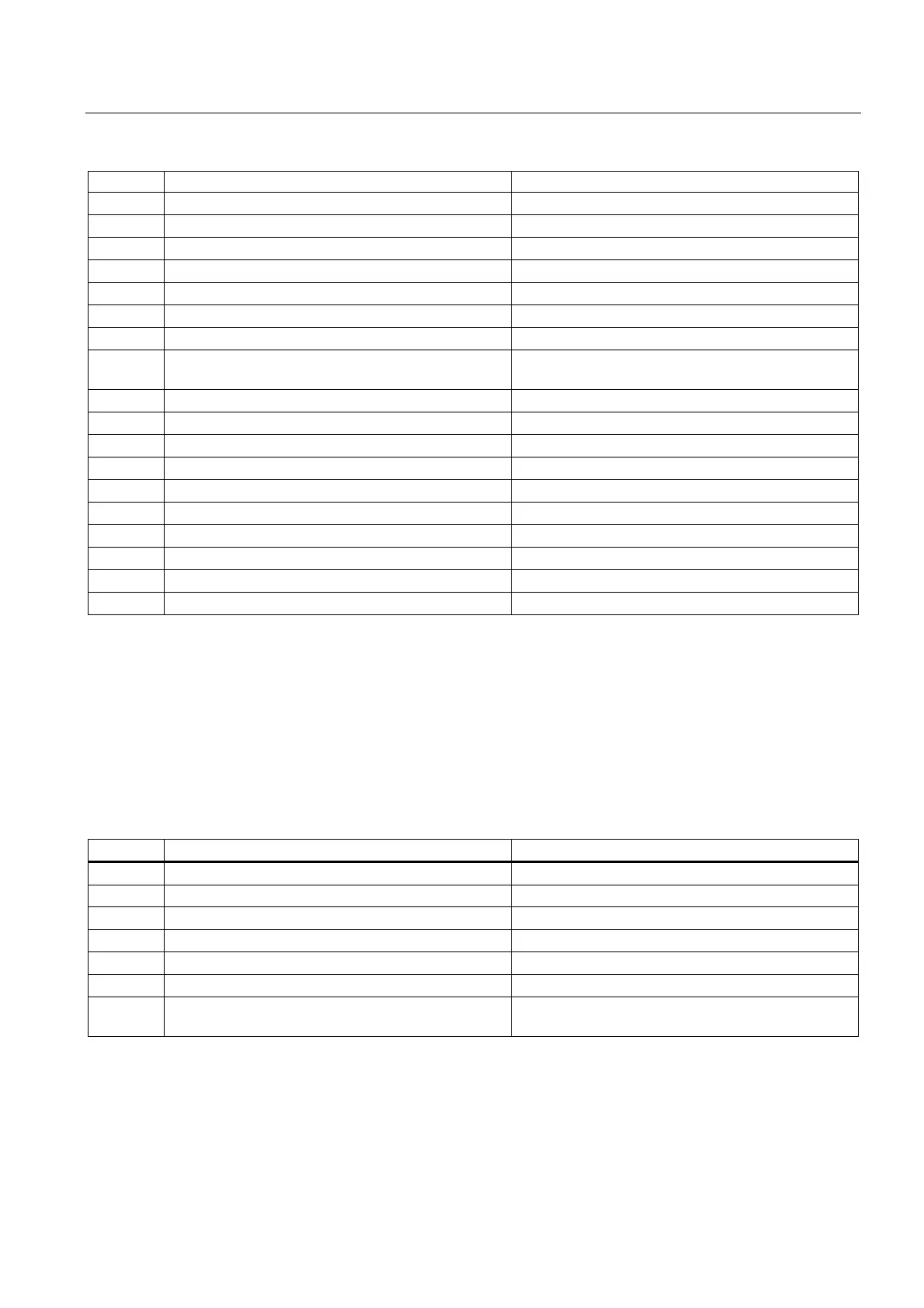

5.2 5.2 Setting data

5.2.1 Channel-specific setting data

Number Identifier: $SC_ Description

42600 JOG_FEED_PER_REF_SOURCE Revolutional feedrate control in JOG mode

42800 SPIND_ASSIGN_TAB Spindle number converter

42900 MIRROR_TOOL_LENGTH Mirror tool length offset

42910 MIRROR_TOOL_WEAR Mirror wear values of tool length compensation

42920 WEAR_SIGN_CUTPOS Mirror wear values of machining plane

42930 WEAR_SIGN Invert sign of all wear values

42940 TOOL_LENGTH_CONST Retain the assignment of tool length components

when changing the machining plane (G17 to G19)

Loading...

Loading...