Detailed Description

2.1 Various interface signals and functions (A2)

NC/PLC Interface Signals (Z1)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2-3

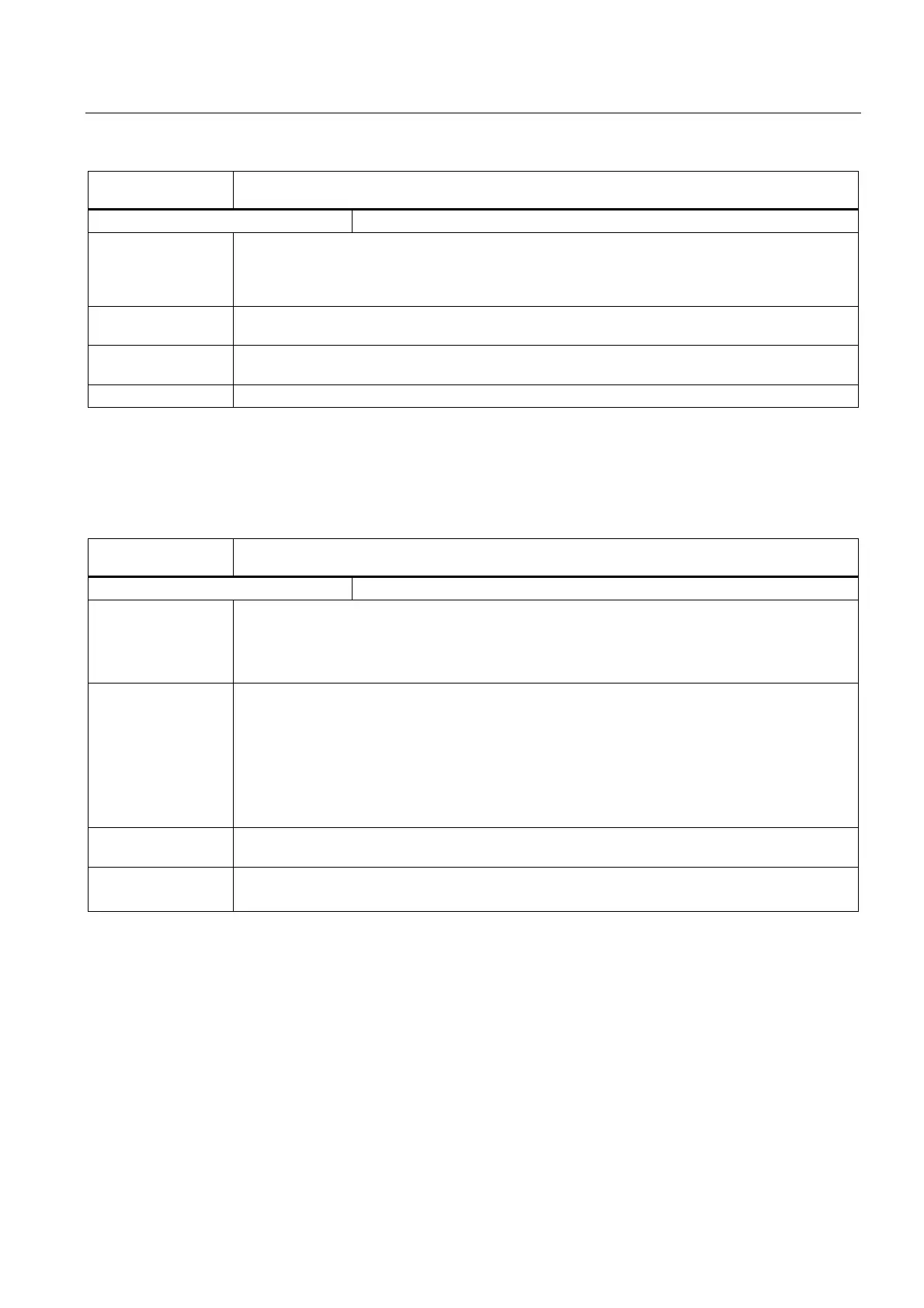

DB10

DBX103.7

MMC101/102 battery alarm

Edge evaluation: no Signal(s) updated: cyclic

Signal state 1 or

edge change 0 → 1

The MMC battery monitoring function has responded. In the event of a power failure, the most

recently modified data and a correct device configuration may be lost.

A corresponding MMC alarm is signaled. Check the MMC backup battery.

An insufficient (low) battery voltage also affects the actual time on the MMC.

Signal state 0 or

edge change 1 → 0

No MMC battery alarm is active.

Signal irrelevant

for ...

SINUMERIK 840/840Di/810D with PCU 50, PCU 20 or PCU 70

References /BH/ Operator Components, Manual, Chapter: "PCU 50 component, replace battery"

2.1.3 Signals from NC to PLC (DB10)

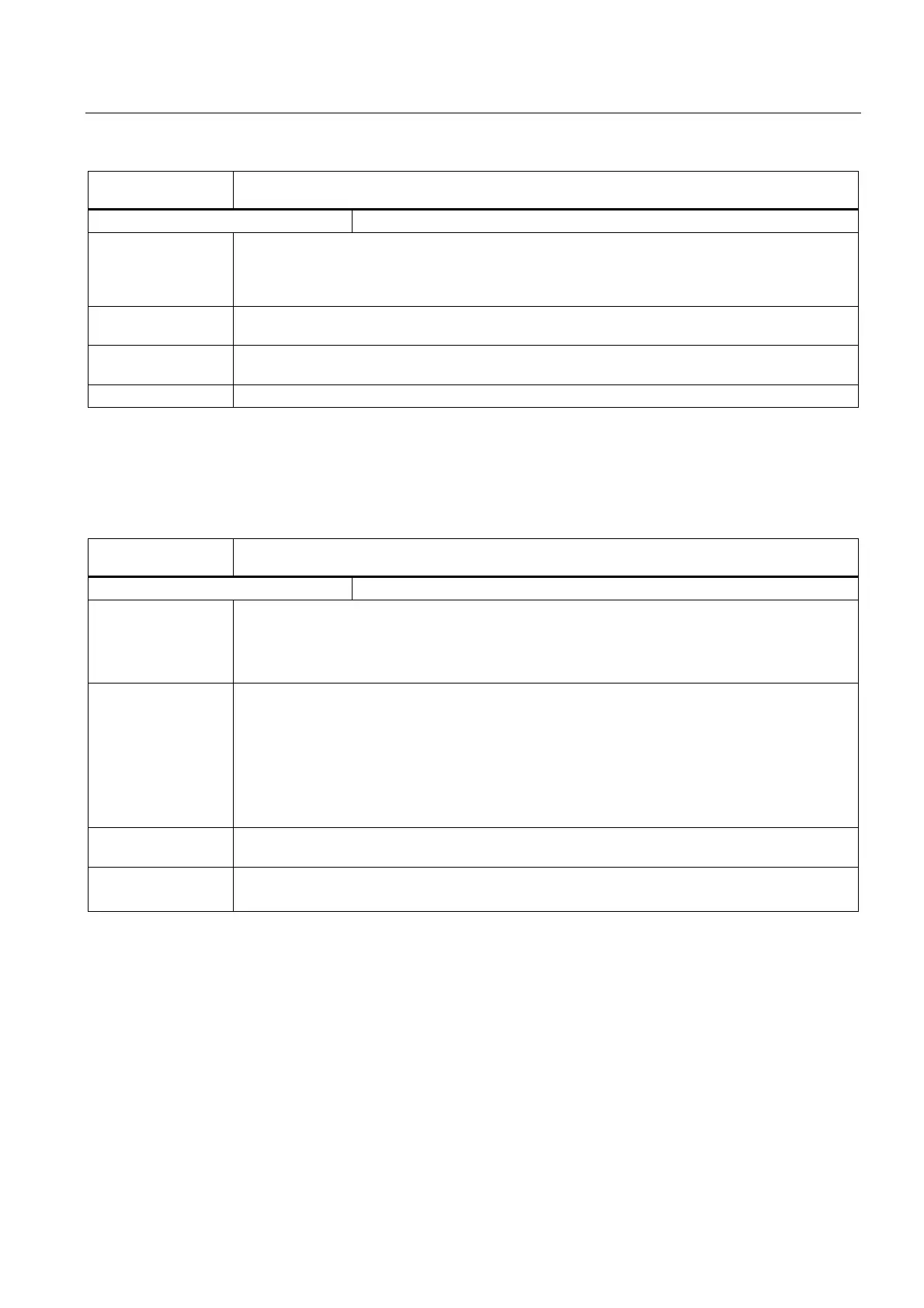

DB10

DBX104.7

NCK-CPU-Ready

Edge evaluation: no Signal(s) updated: cyclic

Signal state 1 or

edge change 0 → 1

The NCK CPU is ready and registers itself cyclically with the PLC.

After a correct initial start and the first complete OB1 cycle (initial setting cycle) the PLC and NCK

continuously exchange sign of life signals.

The PLC basic program sets the interface signal "NCK CPU Ready" to 1.

Signal state 0 or

edge change 1 → 0

The NCK CPU is not ready.

If a sign of life is not received from the NCK, the PLC/NCK interface is neutralized by the PLC basic

program and the interface signal "NCK CPU Ready" is set to 0.

The following measures are initiated by the PLC basic program:

• Status signals from the NCK to the PLC (user interface) are deleted (cleared)

• Change signals for the help functions are deleted

• Cyclic processing of the user interface PLC to NCK is terminated.

Application

example(s)

Individual PLC outputs can, for example, be set to a defined state from the PLC user program.

References /DA/ Diagnostics Guide

/FB1/ Description of Functions Basic Machine; PLC Basic Program (P3)

Loading...

Loading...