Detailed Description

2.3 Setpoint/actual-value system

Velocities, Setpoint/Actual-Value Systems, Closed-Loop Control (G2)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2-39

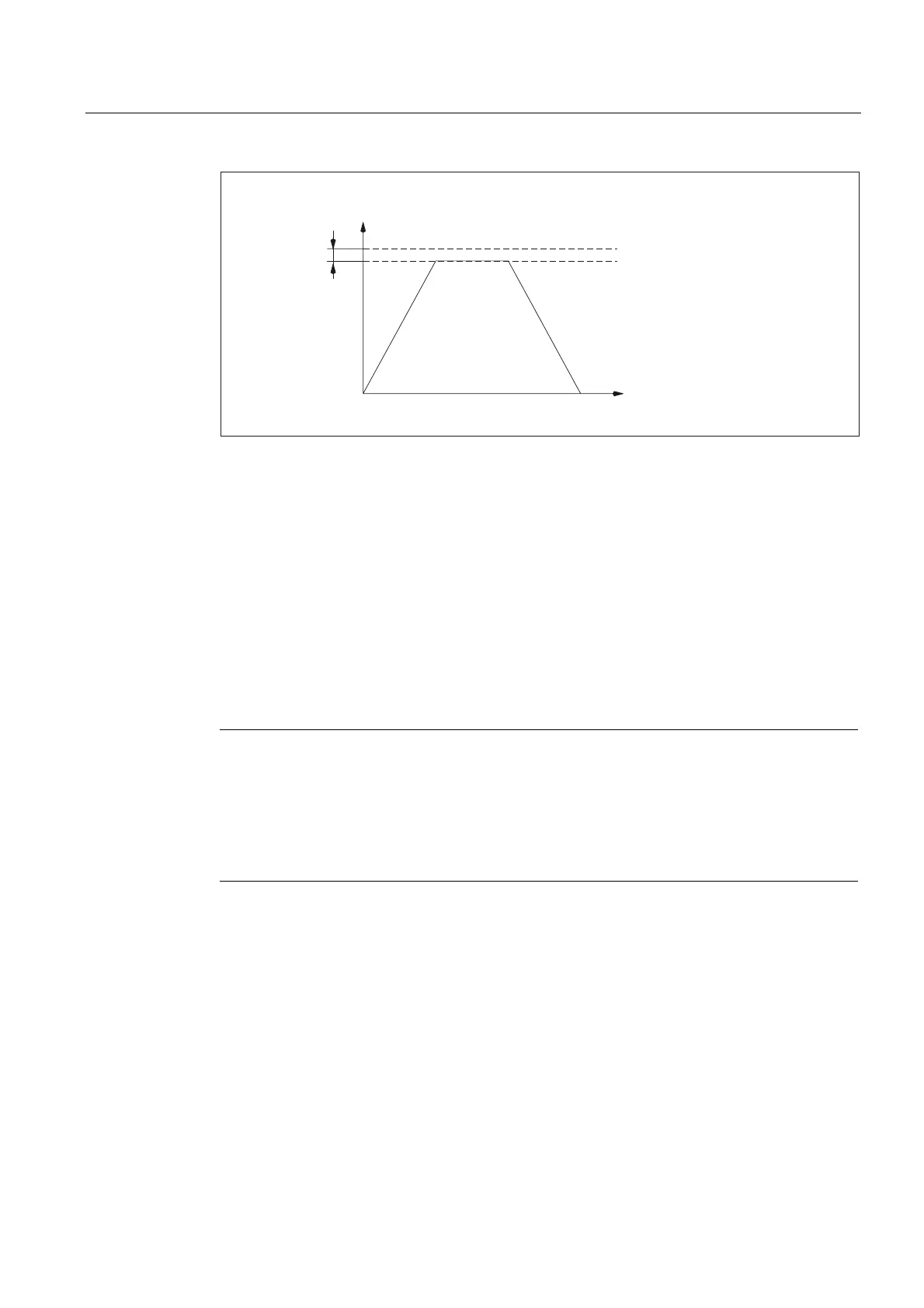

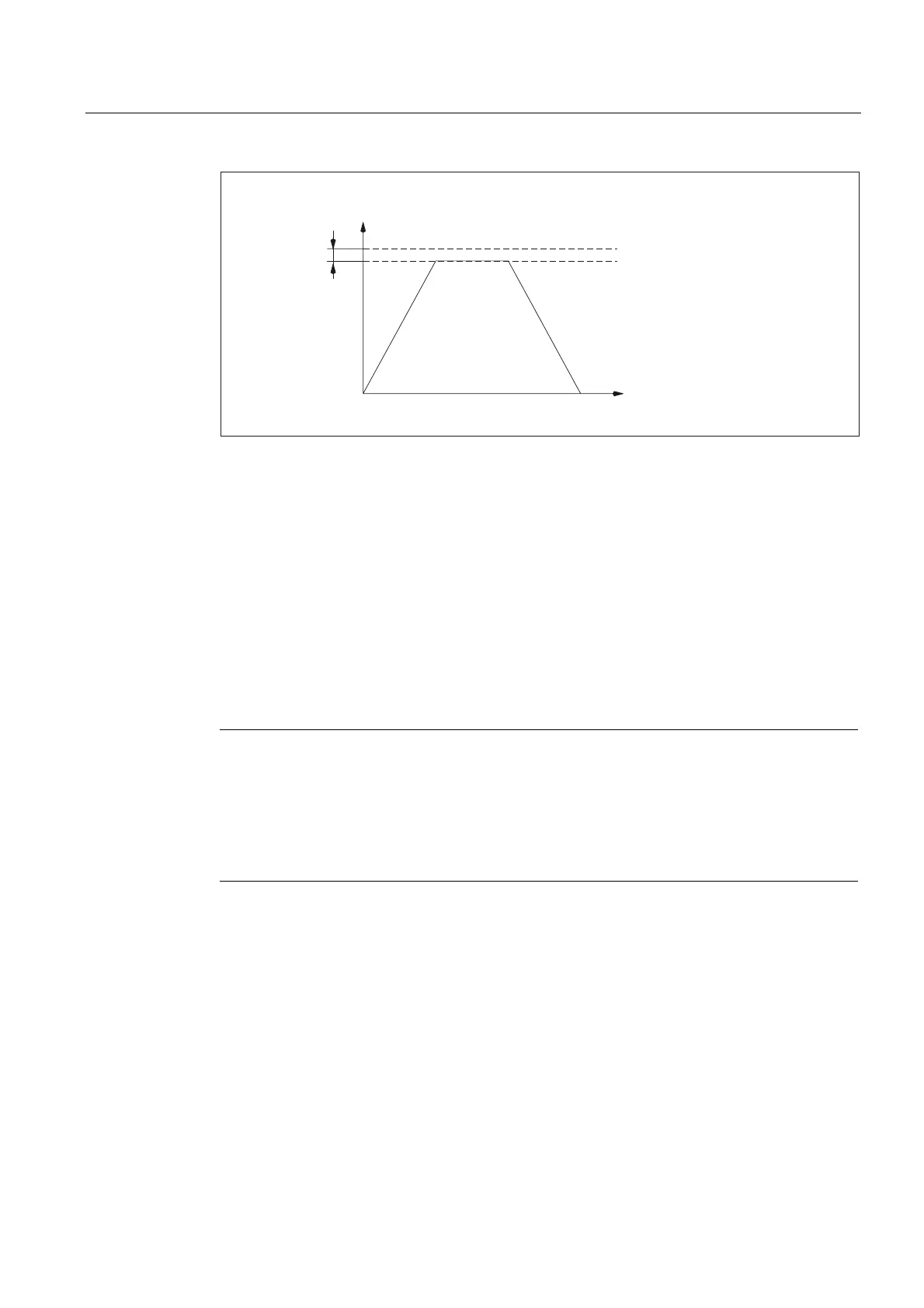

Q

W>V@

0'&75/287B/,0,7

0'0$;B$;B9(/2

0D[D[LVYHORFLW\

6SHHGVHWSRLQW

6HW

0D[VSHHGVHWSRLQW

Fig. 2-5 Maximum speed setpoint

However, due to control processes, the axes should not reach their maximum velocity

(MD32000 $MA_MAX_AX_VELO) at 100% of the speed setpoint, but at 80% to 95%.

For axes, which reach their maximum velocity at around 80% of the speed setpoint range,

the default setting (80%) of machine data:

MD32000 $MA_MAX_AX_VELO (maximum axis velocity)

should be applied.

With SINUMERIK 840D/810, machine data:

MD36210 $MA_CTRLOUT_LIMIT[n] (maximum speed setpoint)

and

MD1405/2405 $MD_MOTOR_SPEED_LIMIT (motor monitoring speed)

must agree.

Note

For more information about setpoint adjustment for SIMODRIVE digital drives, see:

References:

/IAD/ Installation & Startup Guide; "Axes and Spindles".

For more information about setpoint scaling for SIMODRIVE analog drives, see:

References:

/FB3/ Description of Functions, Special Functions; Analog Axis (TE2)

2.3.6 Actual-value processing

Actual-value resolution

In order to be able to create a correctly closed position control loop, the control system must

be informed of the valid actual-value resolution. The axis-specific machine data below are

used for this.

The control calculates the actual-value resolution from the settings made in the MD. The

control parameter sets of the position control are identified as servo parameter sets.

The machining process of the machine forms the basis of the position actual-value

acquisition.

Loading...

Loading...