Detailed Description

2.5 Optimization of the control

Velocities, Setpoint/Actual-Value Systems, Closed-Loop Control (G2)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2-73

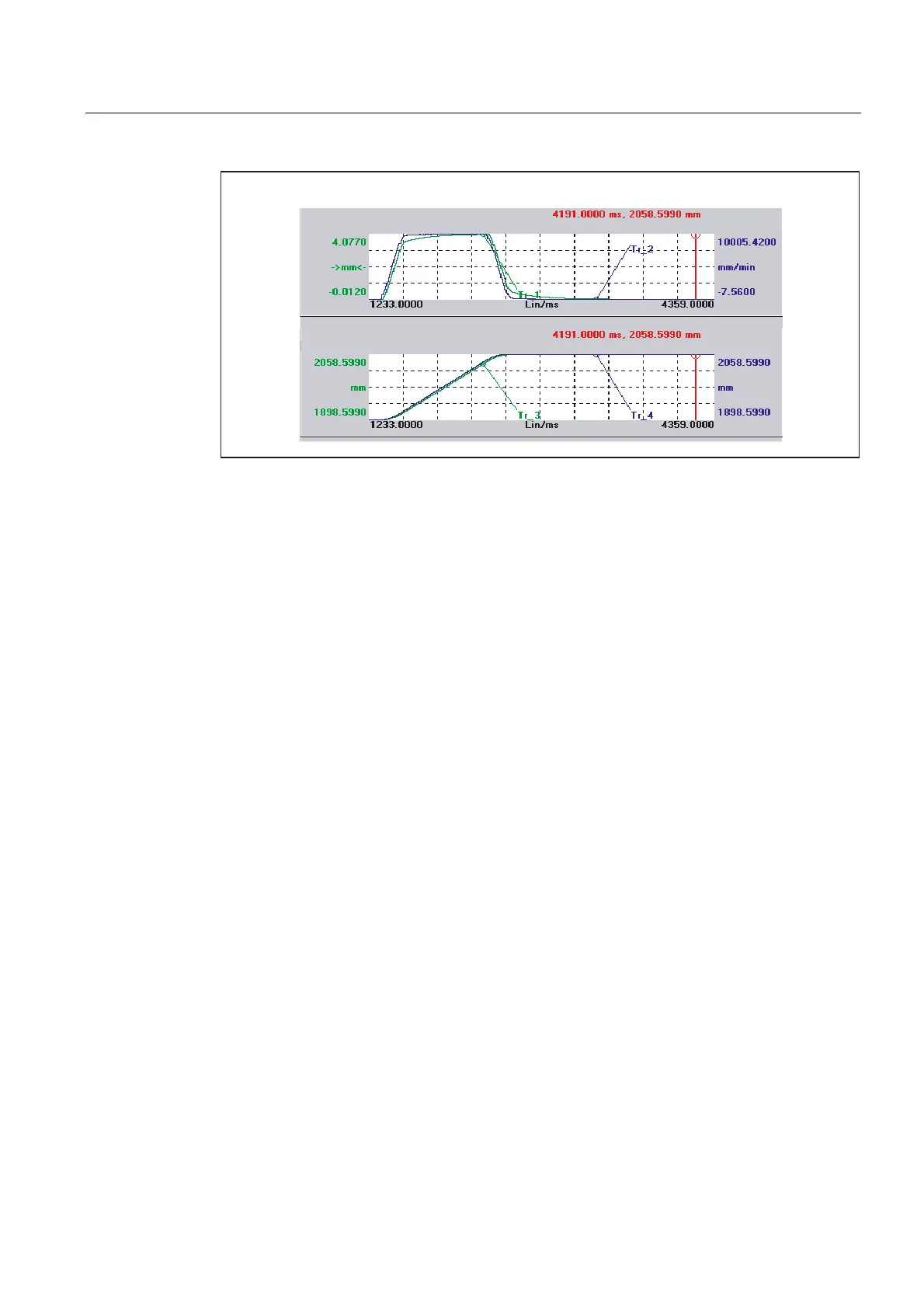

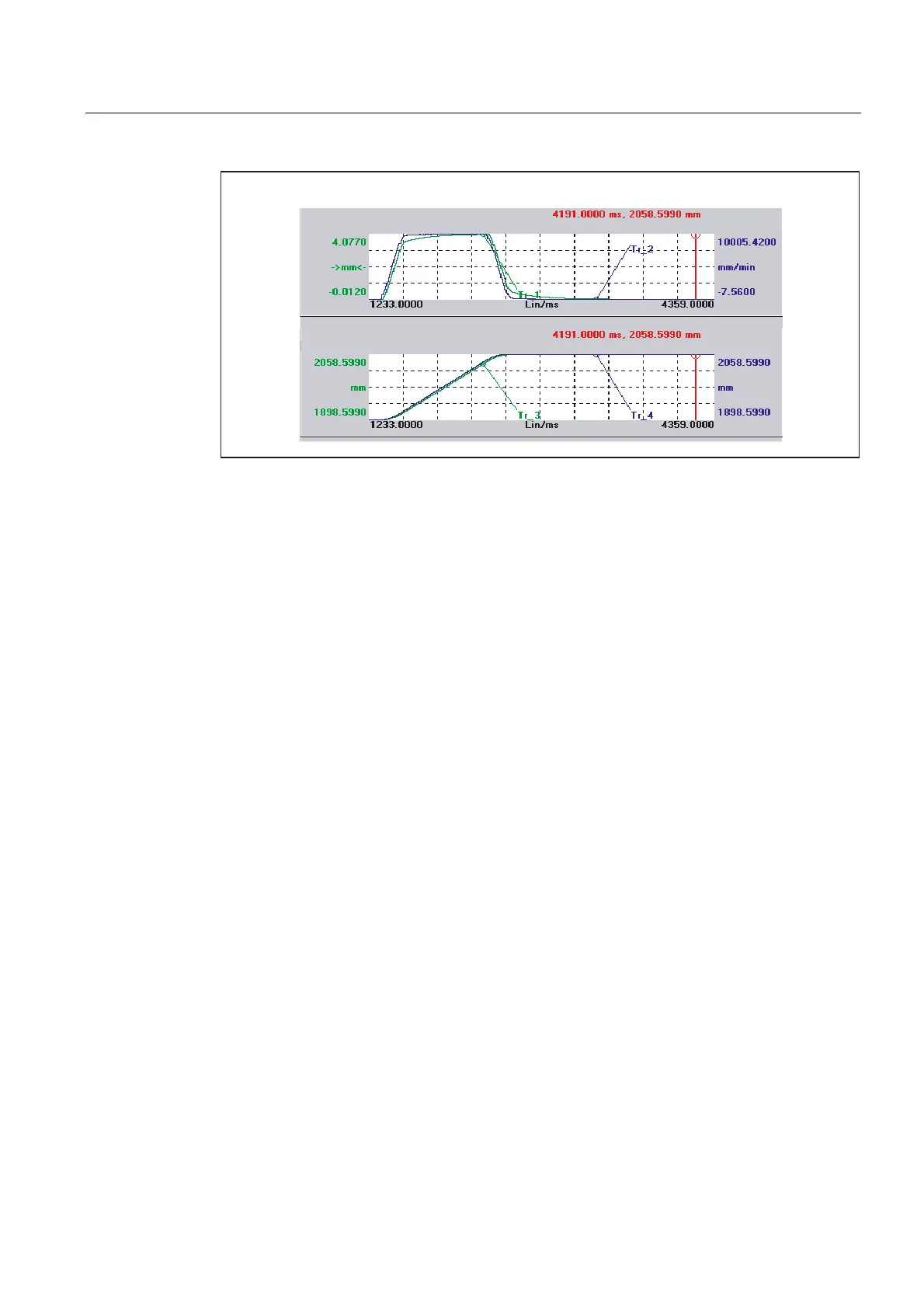

*UDSKLF7U$[LV;7U$[LV;!

*UDSKLF7U$[LV;7U$[LV;!

7U)ROORZLQJHUURU

7U$FWXDOSRVLWLRQPHDVXULQJV\VW

7U$FWXDOYHORFLW\

7U3RVLWLRQVHWSRLQW

0DUNHU;

0DUNHU;

Fig. 2-14 Following error (1), actual velocity (2), position actual value (3), position setpoint (4)

2.5.5 System variable for status of pulse enable

Application

For all applications that must quickly react to pulse enabling, the status of the pulse enable is

imaged to a new system variable in order to accelerate the braking signal.

This system variable is preferably evaluated in synchronized actions. Using the synchronized

action, either a direct output to an NCK output can be carried out or a faster transfer to the

PLC.

Functionality

Since 611D digital drives have no integrated braking signal, the brakes are normally

controlled from the PLC. The brake can be closed again by deleting the pulse enable in the

PLC.

If the pulse enable is deleted due to external events (611D interface, terminal 663 to the

PLC) or due to drive or axis errors, the PLC can close the brake only with a delay, since the

transport of the pulse enable signal via servo and interpolator requires 2 to 3 interpolator

cycle clocks. In the worst case, the PLC needs another two PLC cycles. With hanging axes

and linear motors, this is often slow.

System variable for enabling the drive power

Since the function must be available for all kinds of drives in the same form (also for non-

electrical drives), the variable is given the name "Drive power enable".

Loading...

Loading...