Detailed Description

2.2 Metric/inch measuring system

Velocities, Setpoint/Actual-Value Systems, Closed-Loop Control (G2)

2-16 Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

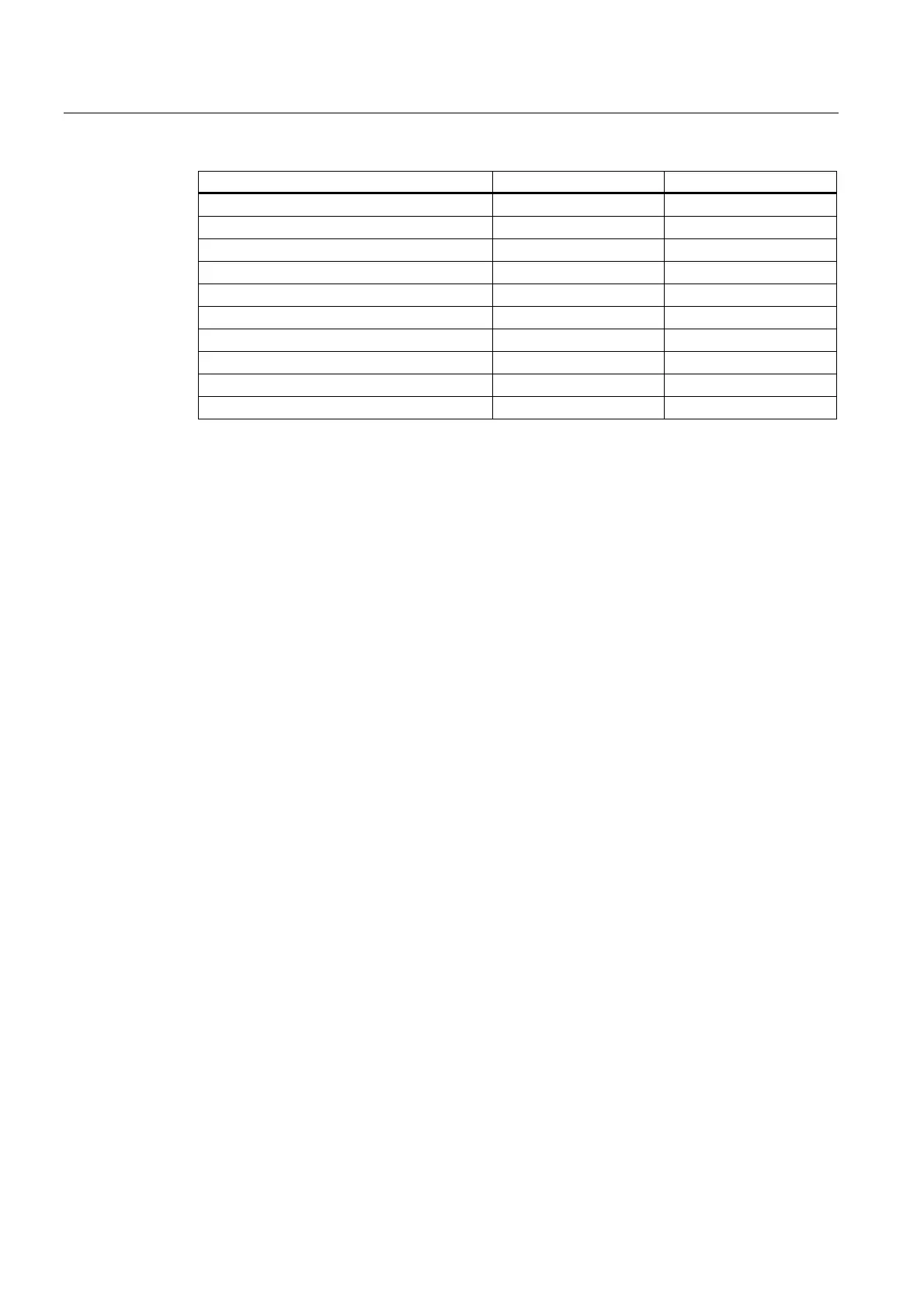

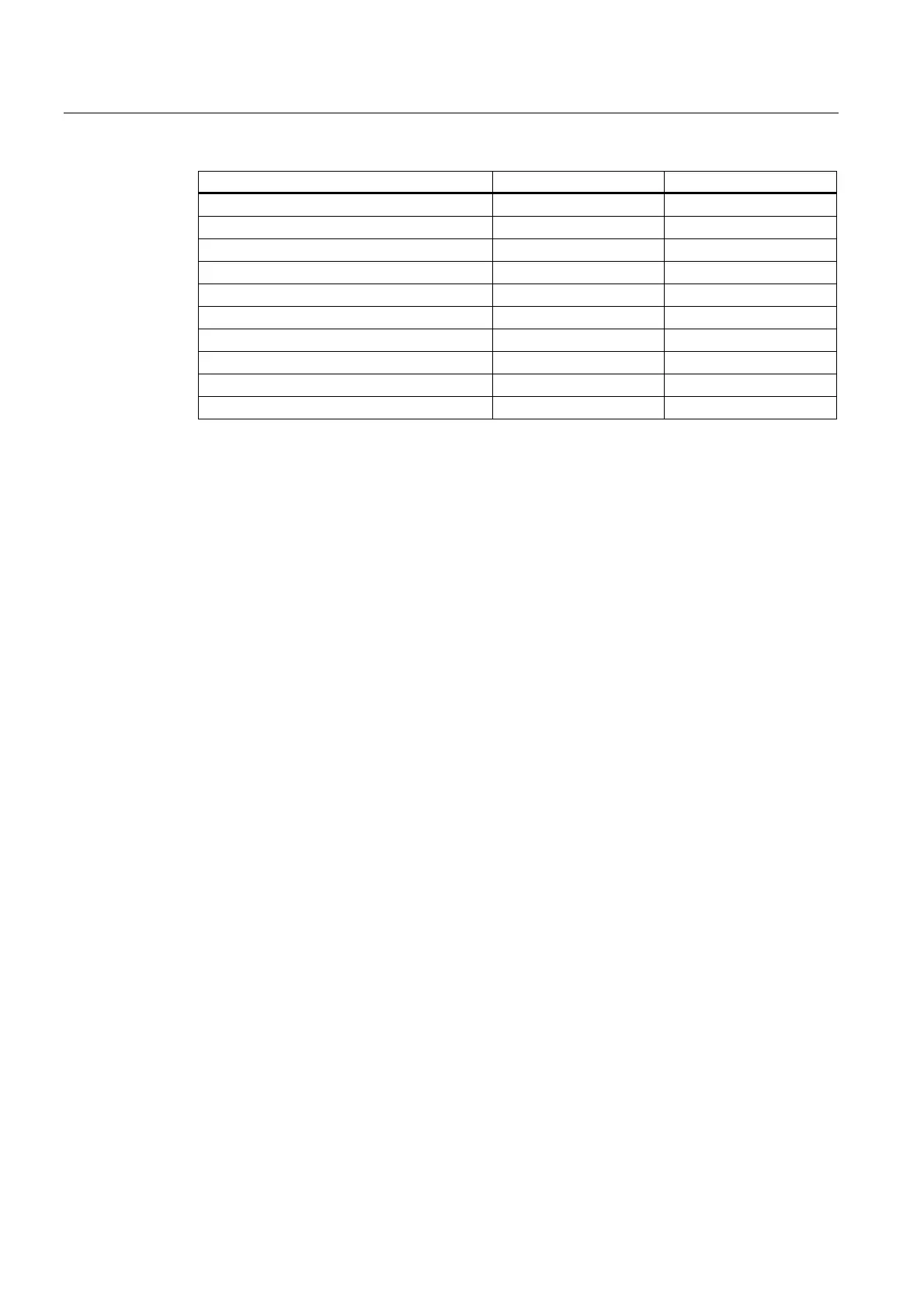

Range G70/G71 G700/G710

Tool offsets G/G P/P

Length-related machine data G/G P/P

Length-related setting data G/G P/P

Length-related system variables G/G P/P

GUD G/G G/G

LUD G/G G/G

PUD G/G G/G

R parameters G/G G/G

Siemens cycles P/P P/P

Jog/handwheel increment factor G/G G/G

References:

/PG/Programming Guide, Fundamentals; List of Addresses

2.2.3 Manual switchover of the basic system

General

The relevant softkey on the HMI in the "Machine" operating area is used to change the

measuring system of the controller.

The change in the measuring system occurs only under the following boundary conditions:

• MD10260 $MN_CONVERT_SCALING_SYSTEM=1

• Bit 0 of MD20110 $MC_RESET_MODE_MASK is set in every channel.

• All channels are in the Reset state.

• Axes doe not traverse with JOG, DRF or PLC.

• Constant grinding wheel peripheral speed (GWPS) is not active.

Actions such as part program start or mode change are disabled for the duration of the

measuring system changeover.

If the measuring system cannot be changed, this is indicated by a message to that effect on

the user interface. These measures ensure that a consistent set of data is always used for a

running program with reference to the measuring system.

The actual change in the measuring system is made by writing all the necessary machine

data and subsequently activating them with a RESET.

Machine data:

MD10240 $MN_SCALING_SYSTEM_IS_METRIC

and the corresponding G70/G71/G700/G710 settings in machine data:

MD20150 $MN_GCODE_RESET_VALUES

are switched automatically and consistently for all configured channels.

The value of machine data:

MD20150 $MC_GCODE_RESET_VALUES[12]

changes between G700 and G710.

Loading...

Loading...