4.1 Test Run

4-12

4.1.8 Basic settings/tuning of function codes < 3 >

When using "vector control without speed sensor (F42

*

=5), auto-tuning should be performed without

regard to the motor type (including the Fuji motors (VG motors) exclusively designed for vector control.

Configure the function codes listed below according to the motor ratings and your machinery design values.

For the motor ratings, check the ratings printed on the motor's nameplate. For your machinery design

values, ask system designers about them.

For details on how to modify the function code data, see Chapter 3, Section 3.4.2 "Setting up function

codes Menu #1 “Data Setting”."

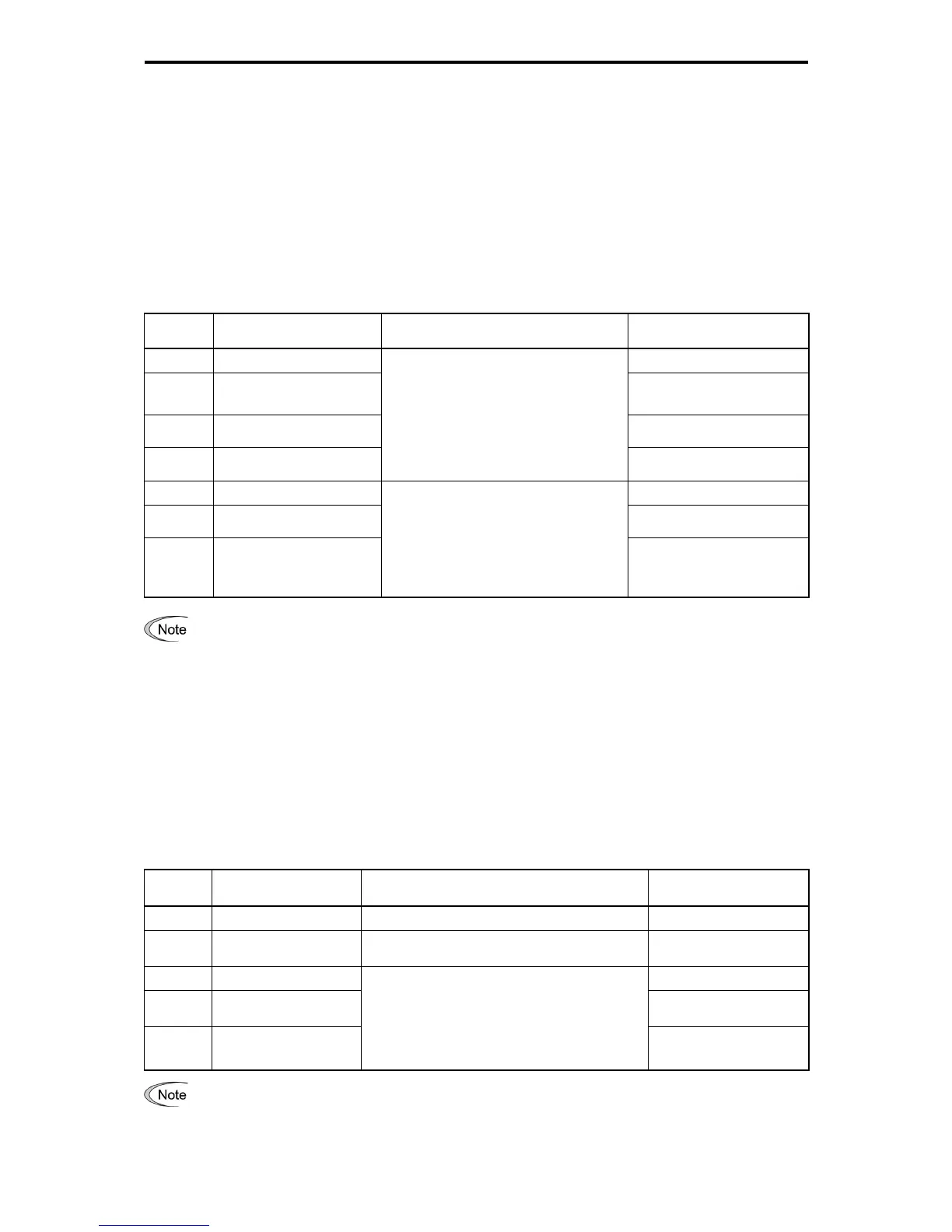

Table 4.1-10

Function

Code

Name Function code data Factory default

f 04

*

Base frequency 1 50.0 (Hz)

f 05

*

Rated voltage at base

frequency 1

Three-phase 200 V: 200 (V)

Three-phase 400 V: 400 (V)

p 02

*

Motor 1 (Rated capacity)

Nominal applied motor

capacity

p 03

*

Motor 1 (Rated current)

Motor ratings (printed on the nameplate

of the motor)

Rated current of nominal

applied motor

f 03

*

Maximum frequency 1 60.0 (Hz)

f 07

Acceleration time 1

(Note)

22 kW or less: 6.00 (s)

30 kW or more: 20.00 (s)

f 08

Deceleration time 1

(Note)

Machinery design values

(Note)

For a test-driving of the motor,

increase values so that they are

longer than your machinery

design values. If the specified

time is short, the inverter may

not run the motor properly.

22 kW or less: 6.00 (s)

30 kW or more: 20.00 (s)

• Be very careful when changing the P02

*

data because doing so automatically updates the data of the

function codes P03

*

, P06

*

to P23

*

, P53

*

to P56

*

, and H46.

• Vector control without speed sensor uses lower rated voltage (base frequency voltage) of the motor.

However, use the normal value for the base frequency voltage. After auto-tuning, the motor voltage will

be automatically lowered from the base frequency voltage.

• Not available for the MD mode.

When combining the inverter with the Fuji motors (VG motors) exclusively designed for vector control,

configure the function codes as listed below, and perform auto-tuning after initializing the motor (H03 = 2).

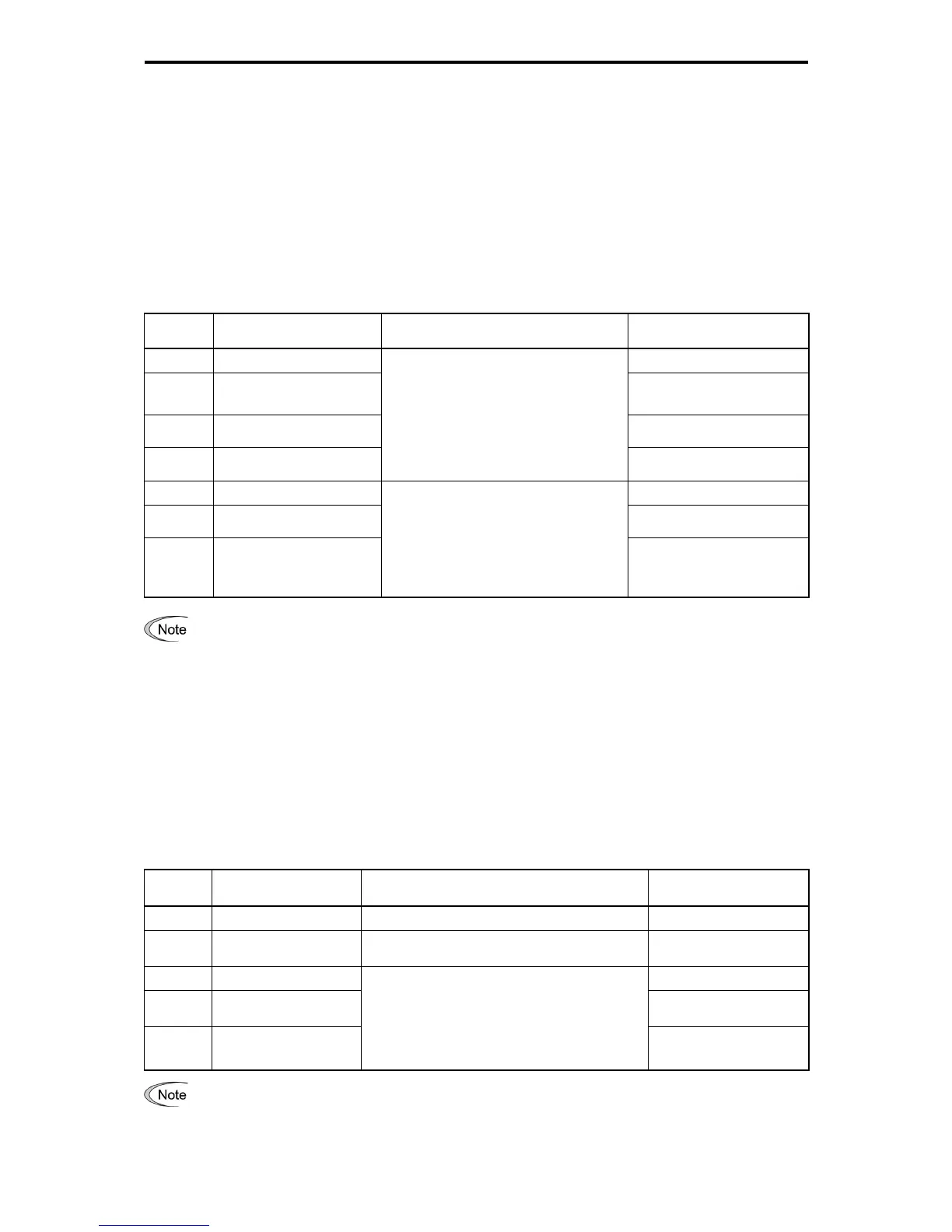

Table 4.1-11

Function

Code

Name Function code data Factory default

p 99

*

Motor 1 selection 2: Motor characteristics 2 (VG motor) 0: Motor characteristics 0

p 02

*

Motor 1

(Rated capacity)

Capacity of motor connected

Nominal applied motor

capacity

f 03

*

Maximum frequency 1 60.0 (Hz)

f 07

Acceleration time 1

(Note)

22 kW or less: 6.00 (s)

30 kW or more: 20.00 (s)

f 08

Deceleration time 1

(Note)

Machinery design values

(Note)

For a test-driving of the motor, increase

values so that they are longer than your

machinery design values. If the

specified time is short, the inverter may

not run the motor properly.

22 kW or less: 6.00 (s)

30 kW or more: 20.00 (s)

Initializing the motor 1 using the function code H03 (H03 = 2) automatically configures the function codes

F04

*

, F05

*

, P01

*

, P03

*

, P06

*

to P23

*

, P53

*

to P56

*

, and H46. Perform auto-tuning after this auto

configuration.

Loading...

Loading...