2.2 Wiring

2-15

Chapter 2 INSTALLATION AND WIRING

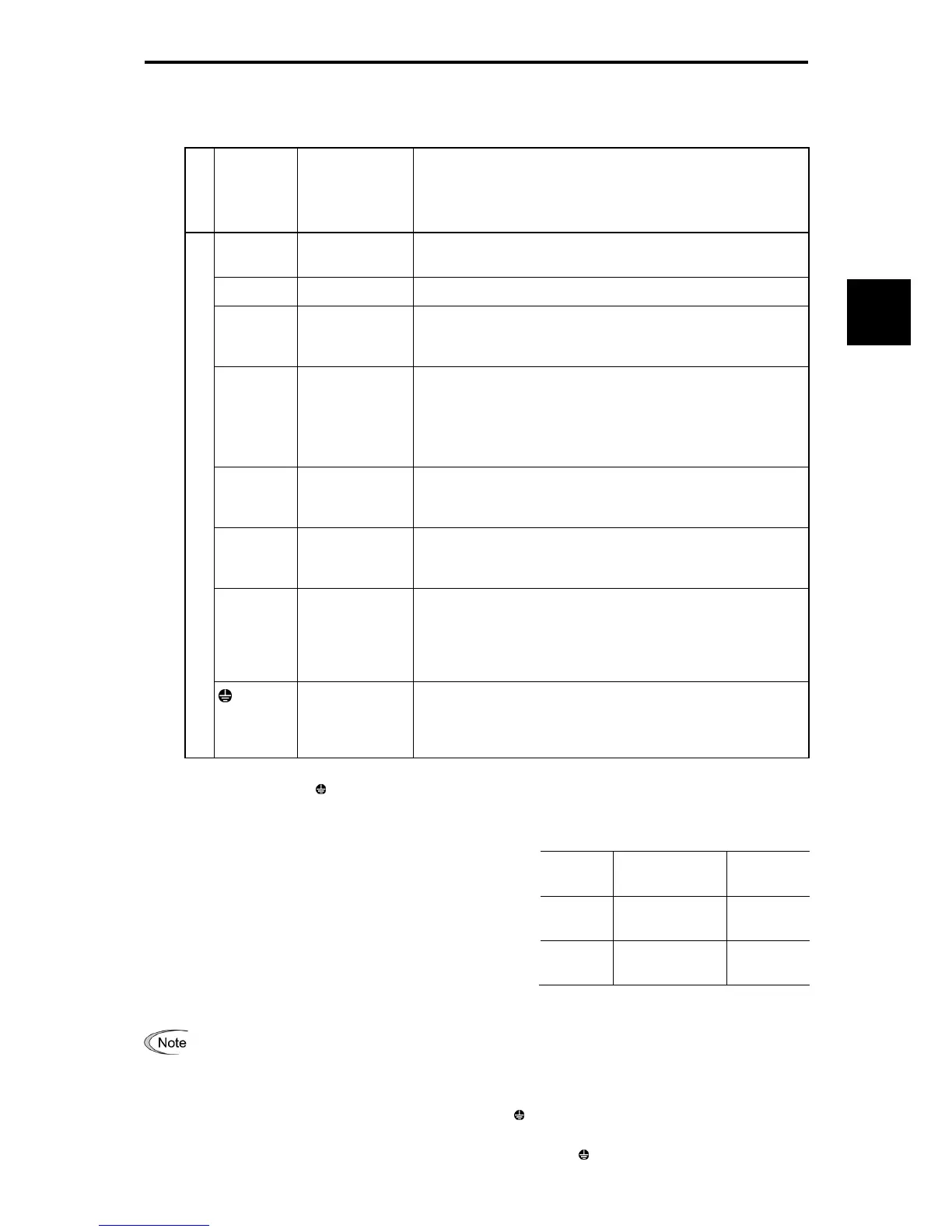

[3] Description of terminal functions (main circuit terminals)

Table 2.2-4

Classification

Symbol Name Functional description

L1/R, L2/S,

L3/T

Main circuit power

input

Connect the three-phase input power lines.

U, V, W Inverter output Connect a three-phase motor.

R0, T0

Auxiliary power

input for the

control circuit

For a backup of the control circuit power supply, connect AC

power lines same as that of the main power input. (For inverters

with 1.5 kW or above)

P1, P(+)

For direct current

reactor

connection

Connect a DC reactor (DCR) for correcting power factor.

* HD-mode inverters: A DCR is provided as option for 0.4 to 55

kW, and as standard for 75 kW or above.

LD-mode inverters: A DCR is provided as option for 5.5 to 45

kW, and as standard for 55 kW or above.

P(+), DB

For braking

resistor

connection

Connect a braking resistor (option).

P(+), N(-)

For DC link bus

connection

Connect a DC link bus of other inverter(s). A high power-factor,

regenerative PWM converter is also connectable to these

terminals.

R1, T1

Auxiliary power

input for the fans

Normally, no need to use these terminals. Use these terminals

for an auxiliary power input of the fans in a power system using

a power regenerative PWM converter (RHC series). (For 200 V

class series of inverters with 37 kW and 400 V class series with

75 kW or above)

Main circuit

G

For inverter and

motor grounding

Grounding terminals for the inverter's chassis (or case) and

motor. Earth one of the terminals and connect the other to the

grounding terminal of the motor. Inverters provide a pair of

grounding terminals that function equivalently.

(1) Inverter ground terminal G

The terminal is the ground terminal for the inverter chassis

(case). Always connect to ground for safety and as a

countermeasure for noise. To prevent accidents such as electric

shock and fire, the electric facility technical standards require

grounding construction for metallic frames in electric

instruments.

Follow the steps below in connecting the ground terminal on the

power supply side.

1) Connect to a class D grounding electrode (200 V class series)

or a class C grounding electrode (400 V class series)

according to the electric facility technical standards.

2) The grounding wire should be thick, with large surface area,

and as short as possible.

The 200 V/400 V class series of inverters (5.5 to 11 kW) with a built-in EMC filter have three grounding

terminals. To achieve more effective noise reduction, connect the ground line to the designated

grounding terminal.

( Chapter 13, Section 13.3.2 "Recommended installation method"

(2) Inverter output terminals U, V, W, motor ground terminal

G

1) Connect the 3 phase motor terminals U, V, and W while matching the phase sequence.

2) Connect the ground line of the outputs (U, V, W) to the ground terminal (

G).

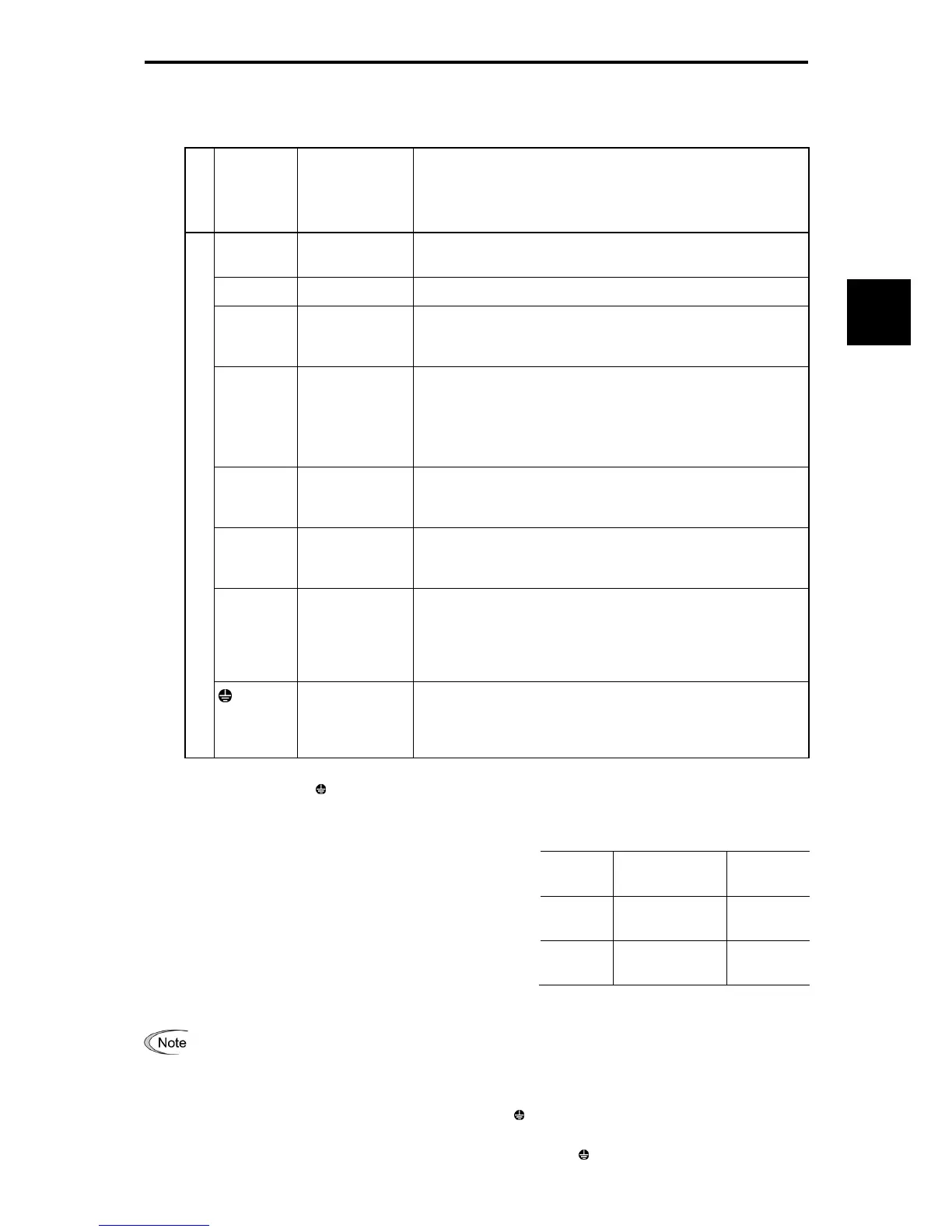

Table 2.2-5 Grounding Instruments in

Compliance with the Electric Facility Technical

Standards

Power

supply

voltage

Grounding class Grounding

resistance

Three-

phase

200 V

Class D

grounding

100 Ω or

below

Three-

phase

400 V

Class C

grounding

10 Ω or

below

Loading...

Loading...