11.4 Option

11-25

Chapter 11 SELECTING PERIPHERAL EQUIPMENT

11.4 Option

11.4.1 Peripheral equipment options

[1] Braking resistors (DBRs) and braking units

(1) Braking resistors (DBRs)

A braking resistor converts regenerative energy generated from deceleration of the motor to heat for

consumption. Use of a braking resistor results in improved deceleration performance of the inverter.

Refer to Chapter 10, Section 10.2 "Selecting a Braking Resistor."

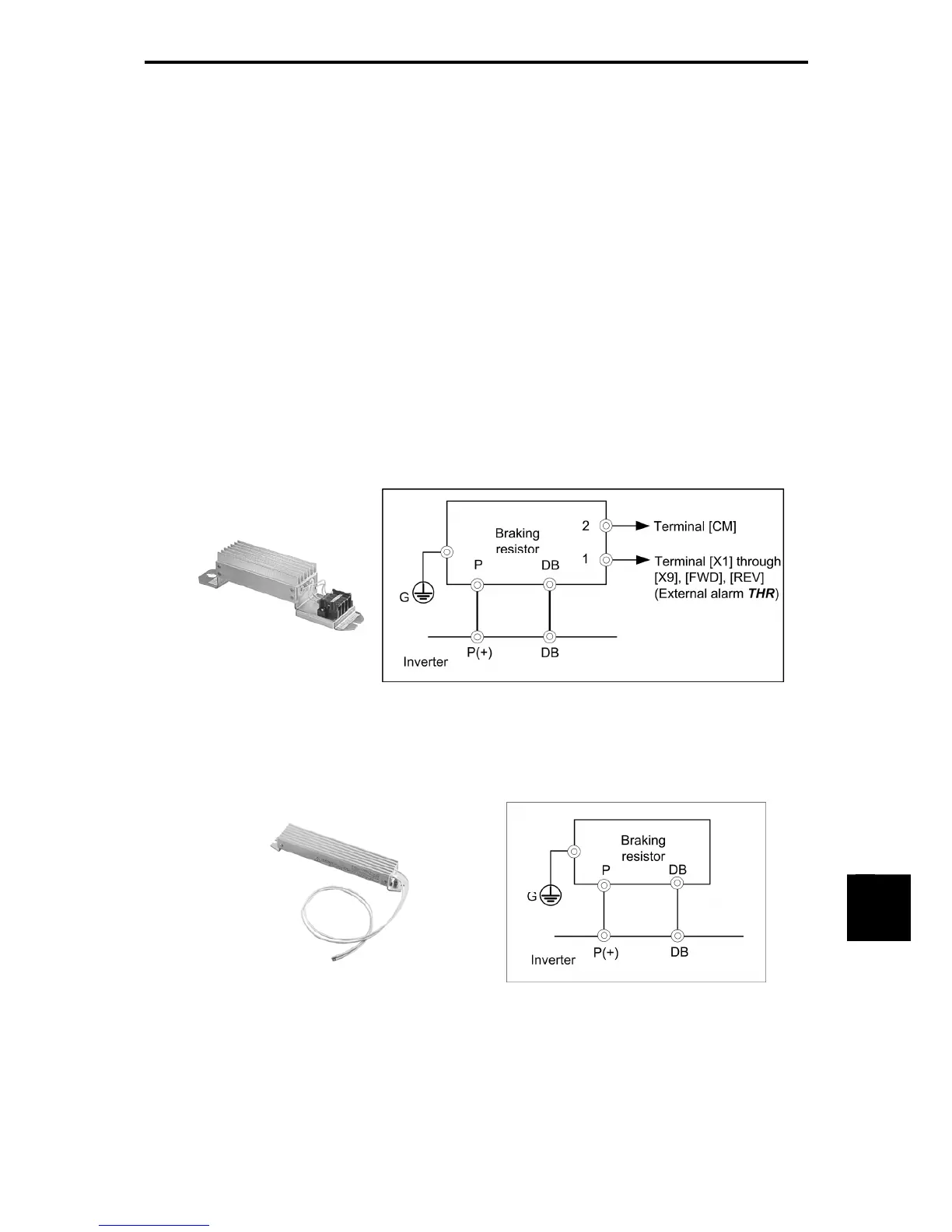

(1.1) Standard model

The standard model of a braking resistor integrates a facility that outputs temperature detection signals. To

ensure that the signal is recognized at one of the digital input terminals of the FRENIC-MEGA, assign the

external alarm THR to any of terminals [X1] to [X9], [FWD] and [REV]. Connect the assigned terminals to

terminals [1] and [2] of the braking resistor. Upon detection of the warning signal (preset detection level:

150°C), the inverter displays alarm

0h2

on the LED monitor and shuts down its power output.

Figure 11.4-1 Braking Resistor (Standard Model) and Connection Example

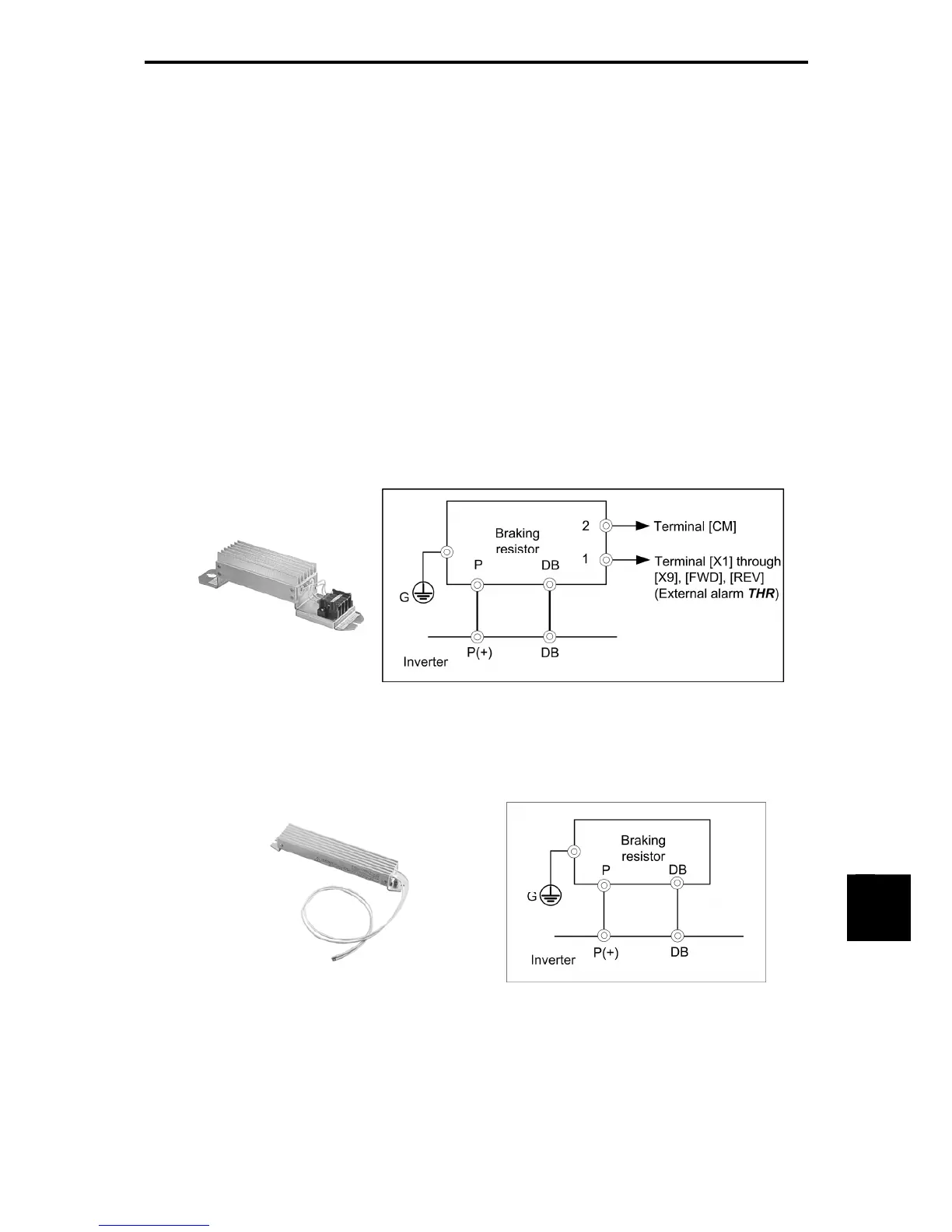

(1.2) 10% ED model

The 10% ED braking resistor does not support overheating detection or warning output, so an electronic

thermal function (function codes F50 and F51) to protect the braking resistor needs to be set.

Figure 11.4-2 Braking Resistor (10% ED Model) and Connection Example

For the specifications and external dimensions of the braking resistors, refer to (3) and (4) in this

section.

Loading...

Loading...