11.4 Option

11-32

[2] Power regenerative PWM converters, RHC series

(1) Overview

Possible to reduce power supply facility capacity

Its power-factor control realizes the same phase

current as the power-supply phase-voltage. The

equipment, thus, can be operated with the

power-factor of almost "1."

This makes it possible to reduce the power

transformer capacity and downsize the other devices,

compared with those required without the converter.

Upgraded braking performance

Regenerated energy occurring at highly frequent

accelerating and decelerating operation and elevating

machine operation is entirely returned to power

supply side.

Thus, energy saving during regenerative operation is

possible.

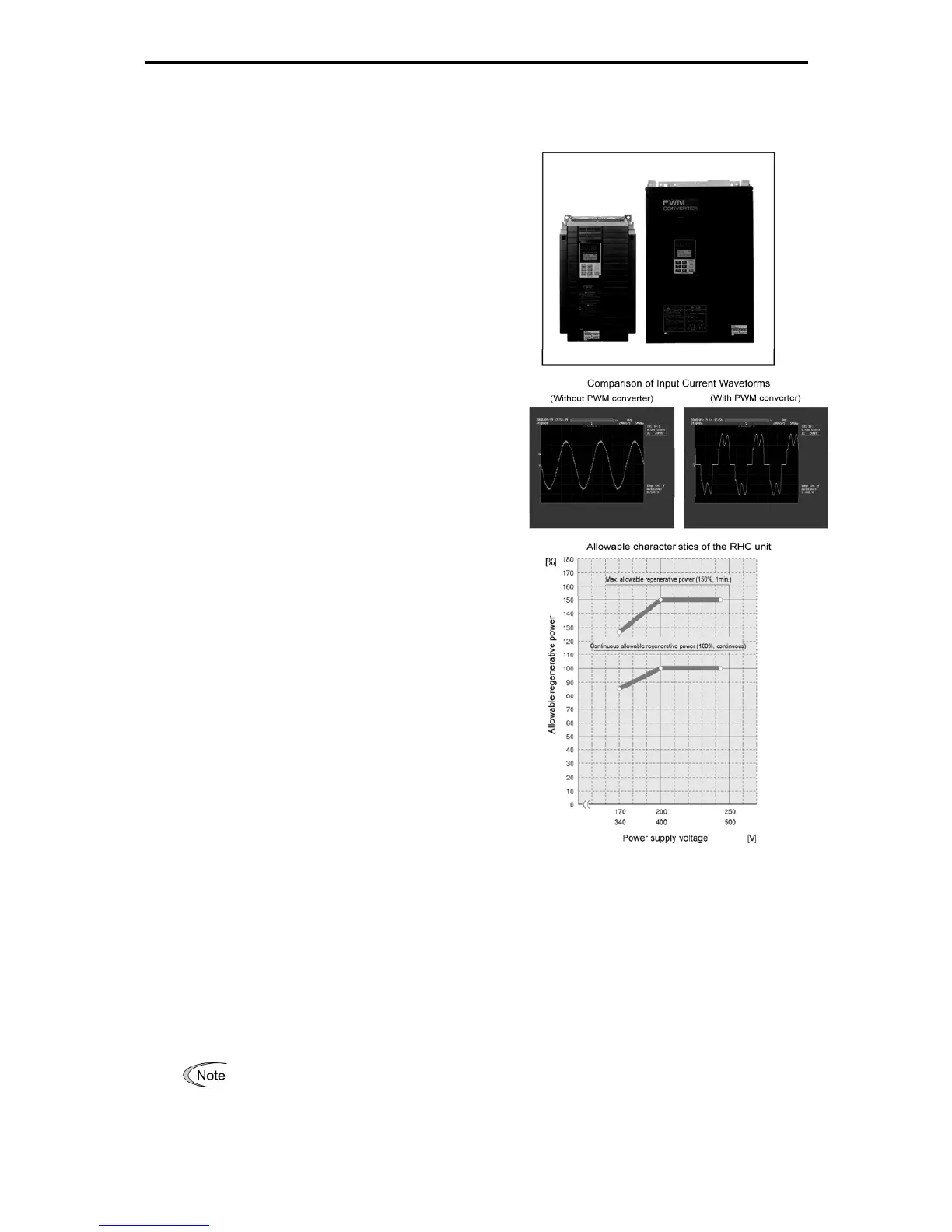

As the current waveform is sinusoidal during

regenerative operation, no troubles are caused to the

power supply system.

Rated continuous regeneration : 100%

Rated regeneration for 1 min 150% (CT use )

120% (VT use )

Enhanced maintenance/protective functions

Failure can be easily analyzed with the trace back

function (option).

(1) The past 10 alarms can be displayed with the

7-segment LEDs.

This helps you analyze the alarm causes and take

countermeasures.

(2) When momentary power failure occurs, the converter

shuts out the gate to enable continuous operation

after recovery.

(3) The converter can issue warning signals like

overload, heat sink overheating, or the end of service

life prior to converter tripping.

Enhanced network support

The converter can be connected to MICREX-SX, F series

and CC-Link master devices (using option).

The RS-485 interface is provided as standard.

When replacing an inverter from an old model

(FRENIC5000VG7S or FRENIC5000G11S) to

FRENIC-MEGA, changes to cabling may be

required. For details, refer to Appendix H.

Loading...

Loading...