9-7

dummyheaddummyhead

LUBRICATION SYSTEM

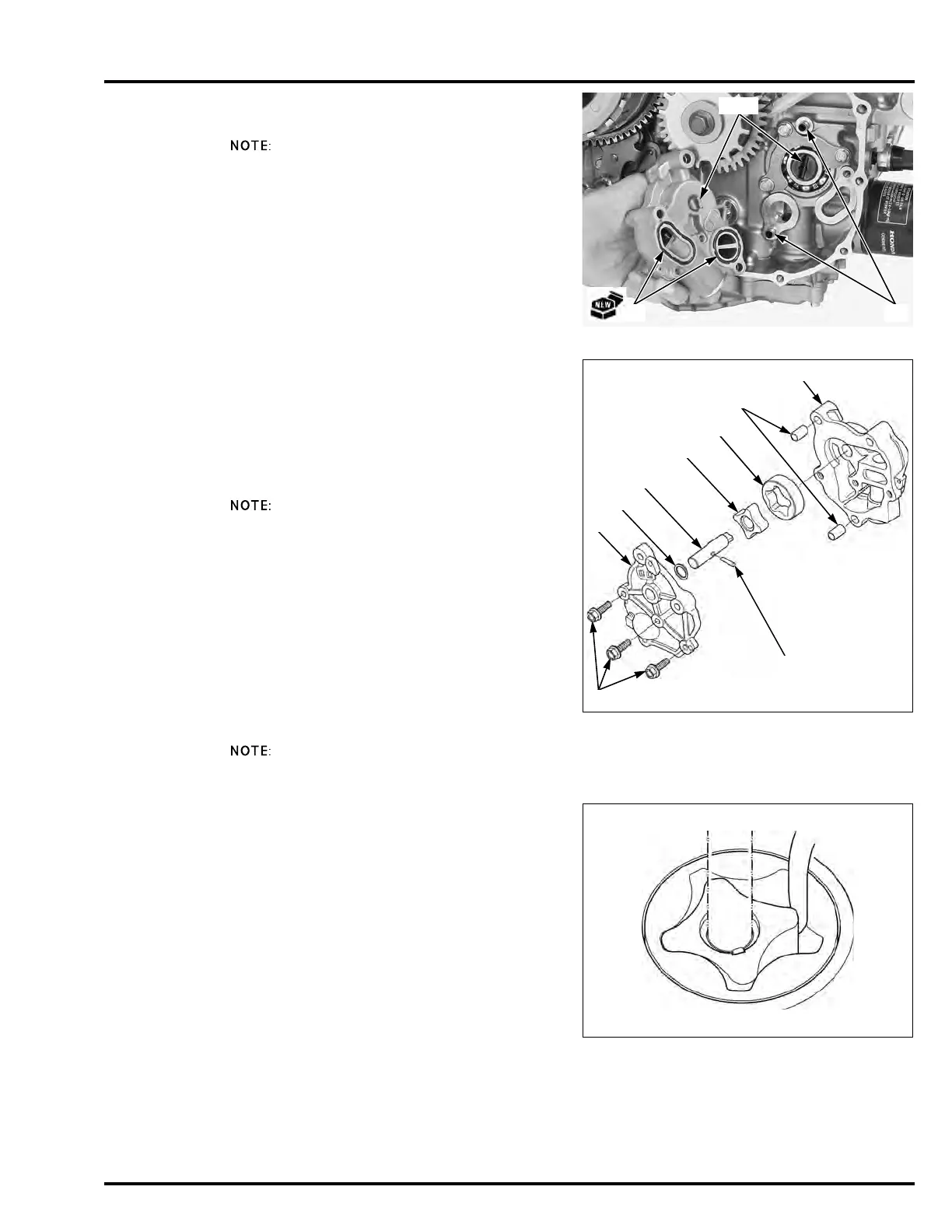

Remove the O-rings [1] and dowel pins [2].

Installation is in the reverse order of removal.

• Replace the O-rings with a new one.

• Align the oil pump shaft tab with the balancer shaft

slit.

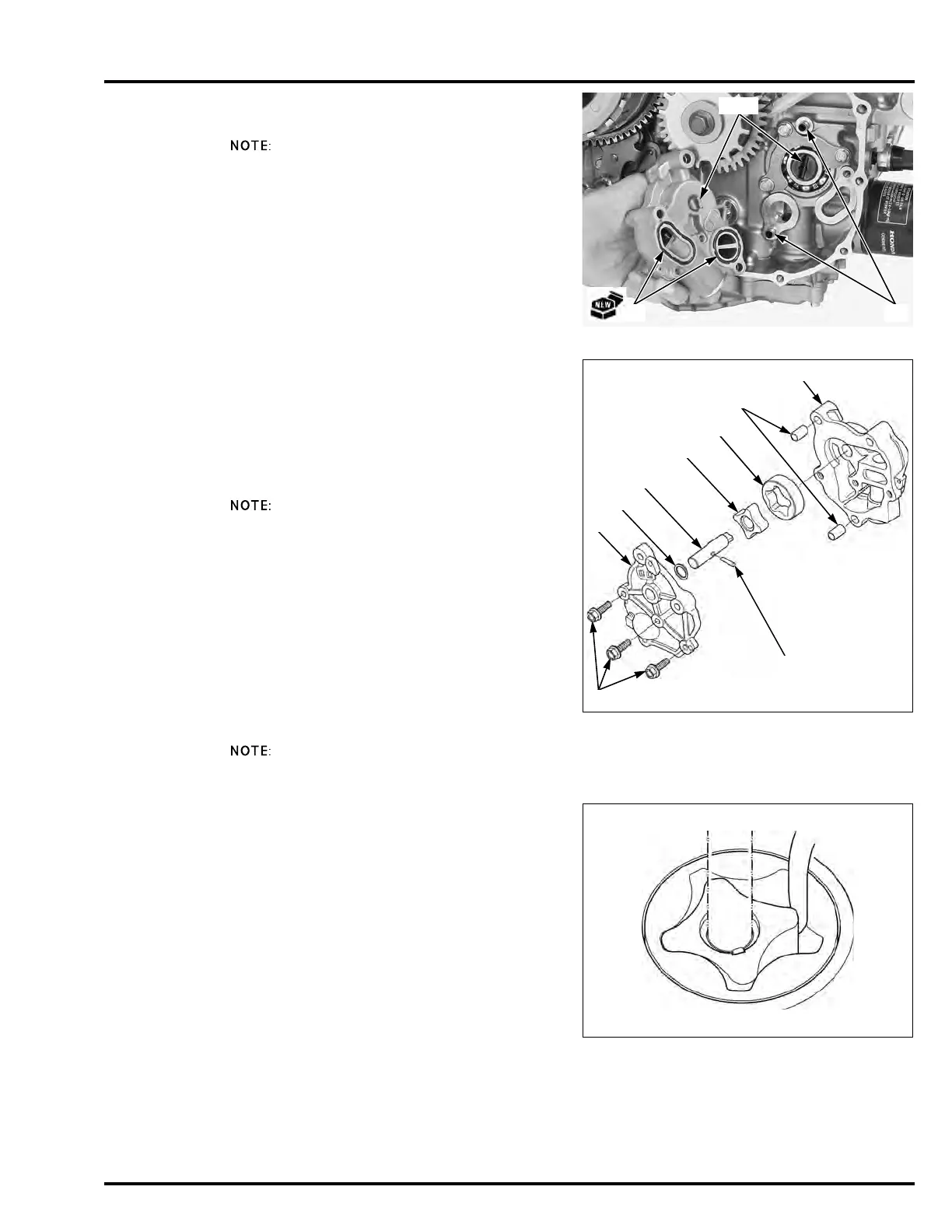

DISASSEMBLY/ASSEMBLY

Remove the bolts [1], oil pump cover [2] and dowel pins

[3].

Remove the thrust washer [4], oil pump shaft [5], drive

pin [6], outer rotor [7] and inner rotor [8] from the oil

pump body [9].

Clean all disassembled parts thoroughly.

Assembly is in the reverse order of disassembly.

Dip all parts in clean engine oil.

INSPECTION

If any portion of the oil pump is worn beyond the service

limit, replace the oil pump as an assembly.

Temporarily install the outer and inner rotors into the oil

pump body.

Temporarily install the drive pin and oil pump shaft.

Measure the rotor tip clearance.

[4]

[1]

[2]

[5]

[6]

[7]

[8]

[9]

[3]

SERVICE LIMIT: 0.20 mm (0.008 in)

Loading...

Loading...