10-21

dummyheaddummyhead

CYLINDER HEAD/VALVES

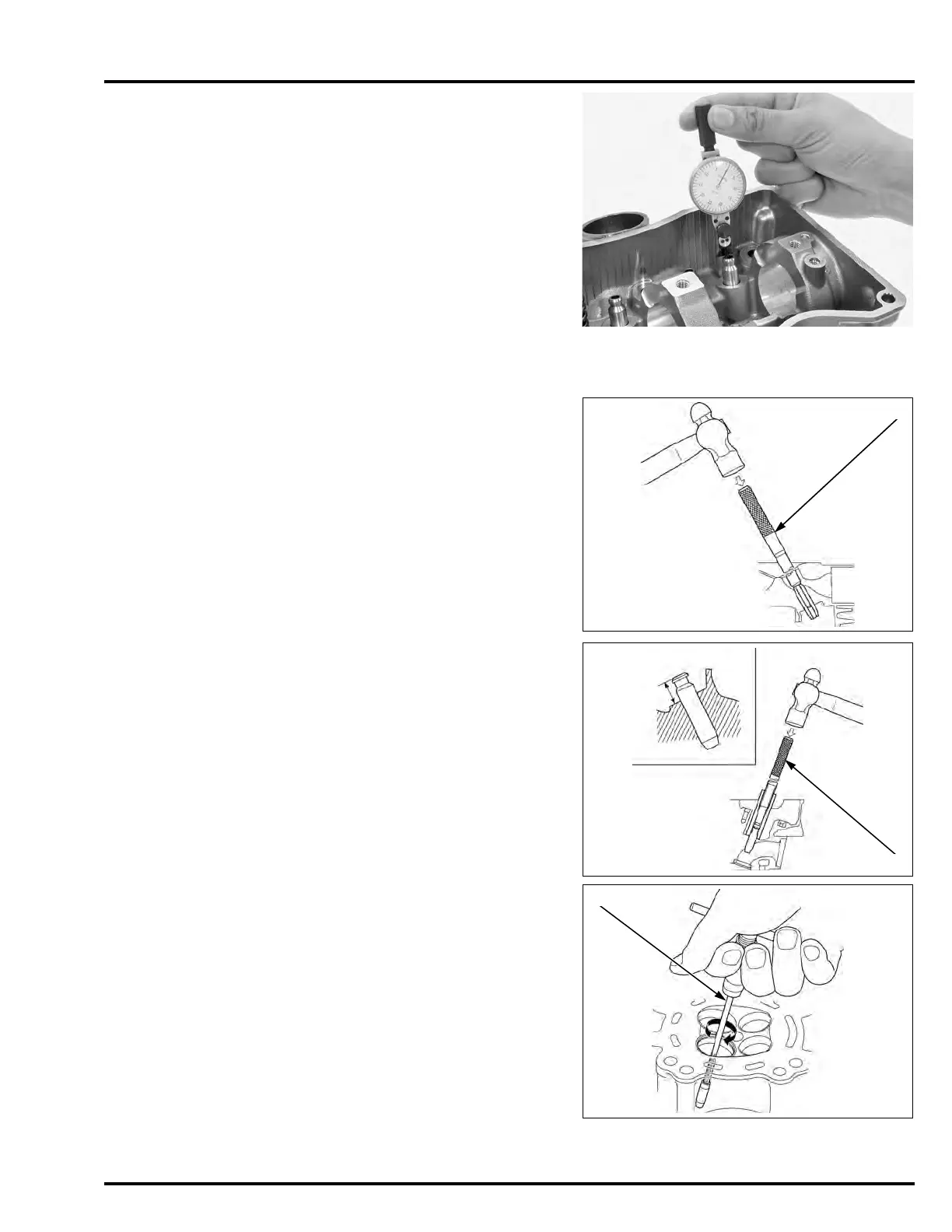

Measure and record each valve guide I.D.

Subtract each valve stem O.D. from the corresponding

guide I.D. to obtain the stem-to-guide clearance.

If the stem-to-guide clearance is out of standard,

determine if a new guide with standard dimensions

would bring the clearance within tolerance. If so,

replace any guides as necessary and ream to fit.

If the stem-to-guide clearance exceeds the service limit

with the new guides, replace the valves and guides.

VALVE GUIDE REPLACEMENT

Chill the replacement valve guides in the freezer

section of a refrigerator for about an hour.

Heat the cylinder head to 100 – 150°C (212 – 302°F)

with a hot plate or oven.

To avoid burns, wear heavy gloves when handling the

heated cylinder head.

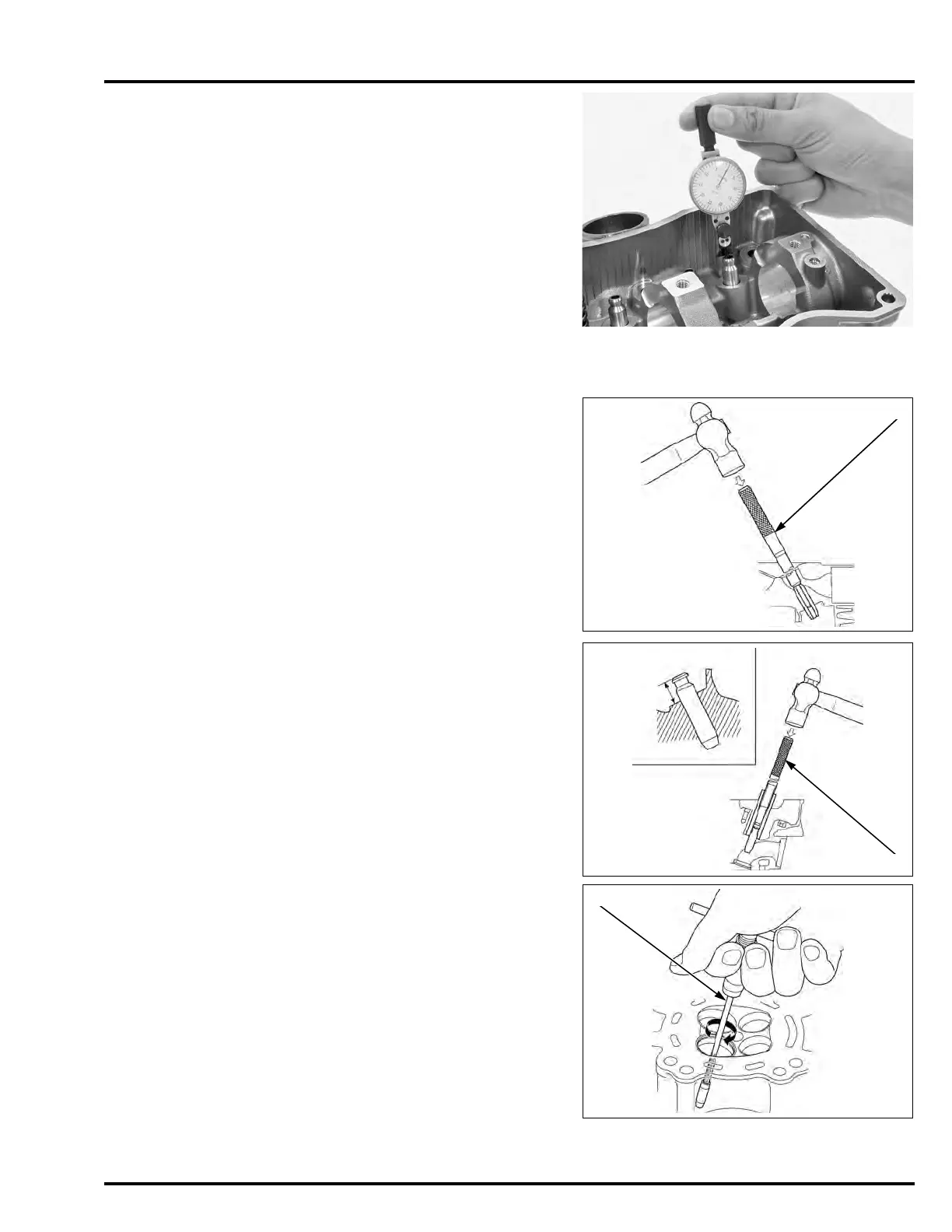

Support the cylinder head and drive out the valve

guides from combustion chamber side of the cylinder

head.

Drive in the valve guides to the specified depth from the

top of the cylinder head.

Let the cylinder head cool to room temperature.

Use cutting oil on

the reamer during

this operation.

Ream new valve guides after installation.

Insert the reamer [1] from the combustion chamber side

of the cylinder head and always rotate the reamer

clockwise.

Clean the cylinder head thoroughly to remove any

metal particles.

Reface the valve seat (page 10-22).

SERVICE LIMIT: 5.04 mm (0.198 in)

SERVICE LIMITS:

IN: 0.075 mm (0.0030 in)

EX: 0.085 mm (0.0033 in)

Reface the valve

seats whenever the

valve guides are

replaced (page 10-

22).

Do not use a torch

to heat the cylinder

head; it may cause

warping.

TOOL:

Valve guide driver [1] 07942-8920000

SPECIFIED DEPTH:

IN: 17.7 – 18.0 mm (0.70 – 0.71 in)

EX: 19.6 – 19.9 mm (0.77 – 0.78 in)

TOOL:

Valve guide driver [1] 07743-0020000

TOOL:

Valve guide reamer, 5.010 mm 07984-MA60001

Loading...

Loading...