15-3

dummyheaddummyhead

CRANKSHAFT/PISTON/CYLINDER

SERVICE INFORMATION

GENERAL

This motorcycle provides cracking connecting rods. Be sure to install each part in its original position, as noted during removal. Do

not reuse the improperly installed connecting rod and bearing cap, because their mating surfaces are damaged.

• The crankcase must be separated to service the following:

– Crankshaft (page 15-5)

– Piston/cylinder (page 15-14)

• Mark and store the connecting rods, bearing caps and bearing inserts to be sure of their correct locations for reassembly.

• The crankpin and main journal bearing inserts are select fit and are identified by color codes. Select replacement bearings from

the code tables. After selecting new bearings, recheck the oil clearance with a plastigauge. Incorrect oil clearance can cause

major engine damage.

• Clean the oil passages in the upper crankcase with compressed air before installing the pistons.

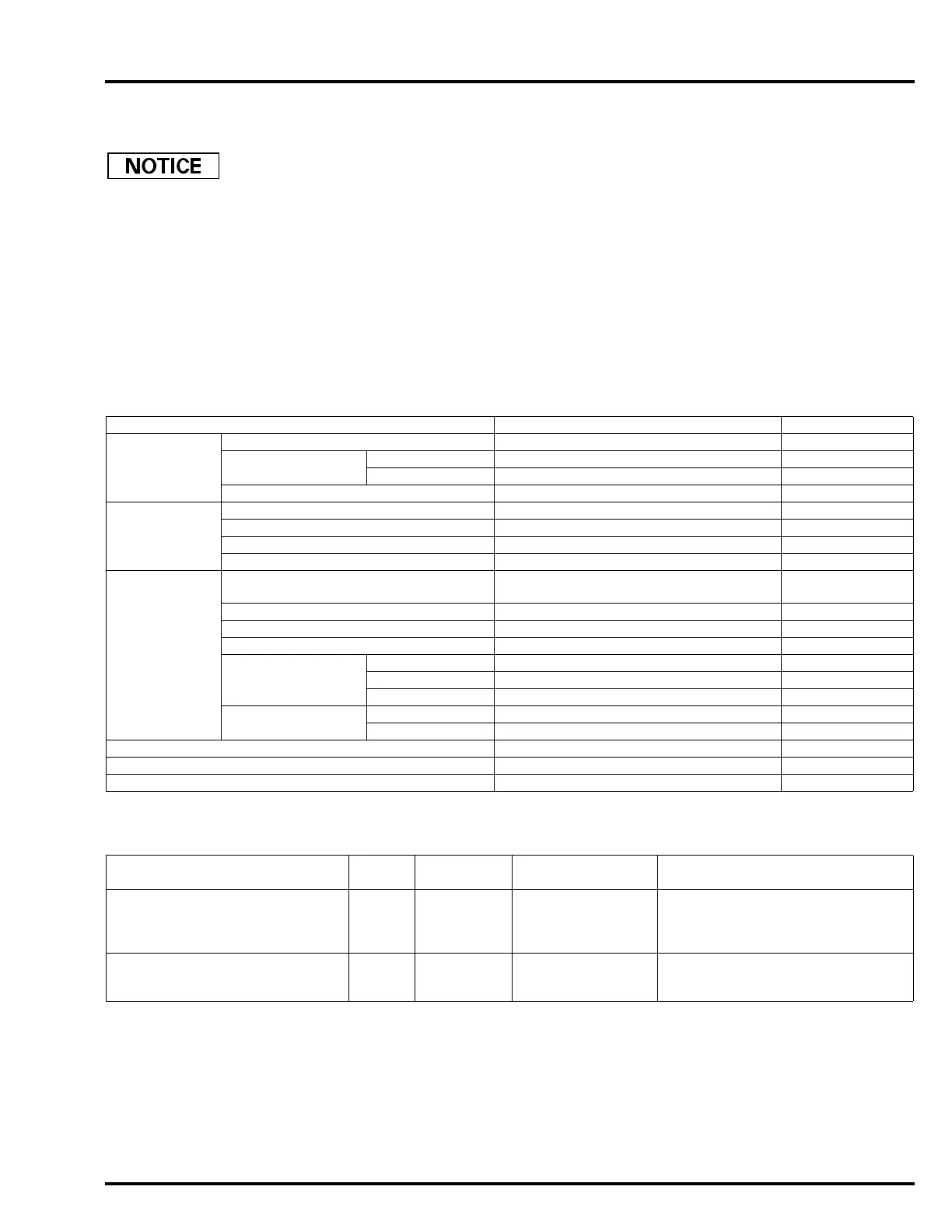

SPECIFICATIONS

Unit: mm (in)

TORQUE VALUES

ITEM STANDARD SERVICE LIMIT

Crankshaft Connecting rod side clearance 0.15 – 0.35 (0.006 – 0.014) 0.45 (0.018)

Runout Right side – 0.03 (0.001)

Left side – 0.03 (0.001)

Main journal bearing oil clearance 0.019 – 0.037 (0.0007 – 0.0015) 0.05 (0.002)

Cylinder I.D. 73.000 – 73.015 (2.8740 – 2.8746) 73.07 (2.877)

Out-of-round – 0.10 (0.004)

Taper – 0.10 (0.004)

Warpage – 0.10 (0.004)

Piston, piston

rings

Piston O.D. at 13 mm (0.5 in) from

bottom

72.976 – 72.990 (2.8731 – 2.8736) 72.970 (2.8728)

Piston pin bore I.D. 18.010 – 18.013 (0.7091 – 0.7092) 18.023 (0.7096)

Piston pin O.D. 17.996 – 18.000 (0.7085 – 0.7087) 17.988 (0.7082)

Piston-to-piston pin clearance 0.010 – 0.017 (0.0004 – 0.0007) 0.035 (0.0014)

Piston ring end

gap

Top 0.15 – 0.30 (0.006 – 0.012) 0.6 (0.02)

Second 0.30 – 0.42 (0.012 – 0.017) 0.6 (0.02)

Oil (side rail) 0.20 – 0.70 (0.008 – 0.028) 0.8 (0.03)

Piston ring-to-ring

groove clearance

Top 0.035 – 0.080 (0.0014 – 0.0032) 0.15 (0.006)

Second 0.030 – 0.055 (0.0012 – 0.0022) 0.13 (0.005)

Cylinder-to-piston clearance 0.010 – 0.039 (0.0004 – 0.0015) 0.05 (0.002)

Connecting rod small end I.D. 17.964 – 17.977 (0.7072 – 0.7078) 17.985 (0.7081)

Crankpin bearing oil clearance 0.026 – 0.044 (0.0010 – 0.0017) 0.05 (0.002)

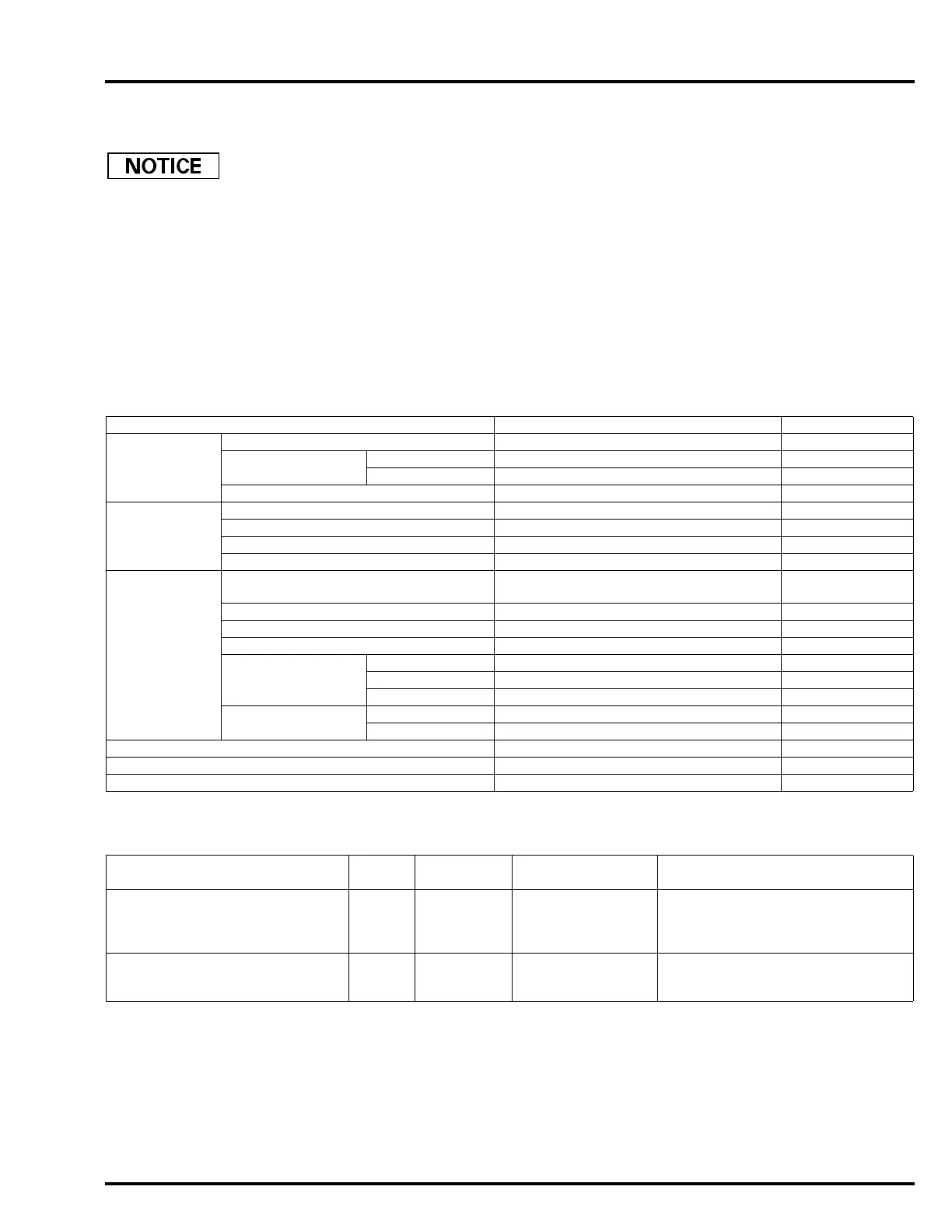

ITEM Q'TY

THREAD TORQUE

REMARKS

DIA. (mm) N·m (kgf·m, lbf·ft)

Crankpin bearing cap bolt 4 6 10 (1.0, 7) + 90° See page 15-7

Replace with a new one.

Apply engine oil to the threads and

seating surface.

Crankcase main journal bolt

(retightening)

6 9 20 (2.0, 15) + 120° See page 15-9

Apply engine oil to the threads and

seating surface.

Loading...

Loading...