M800S/M80/E80 Series Connection and Setup Manual

16 Setup Outline

378

IB-1501269-J

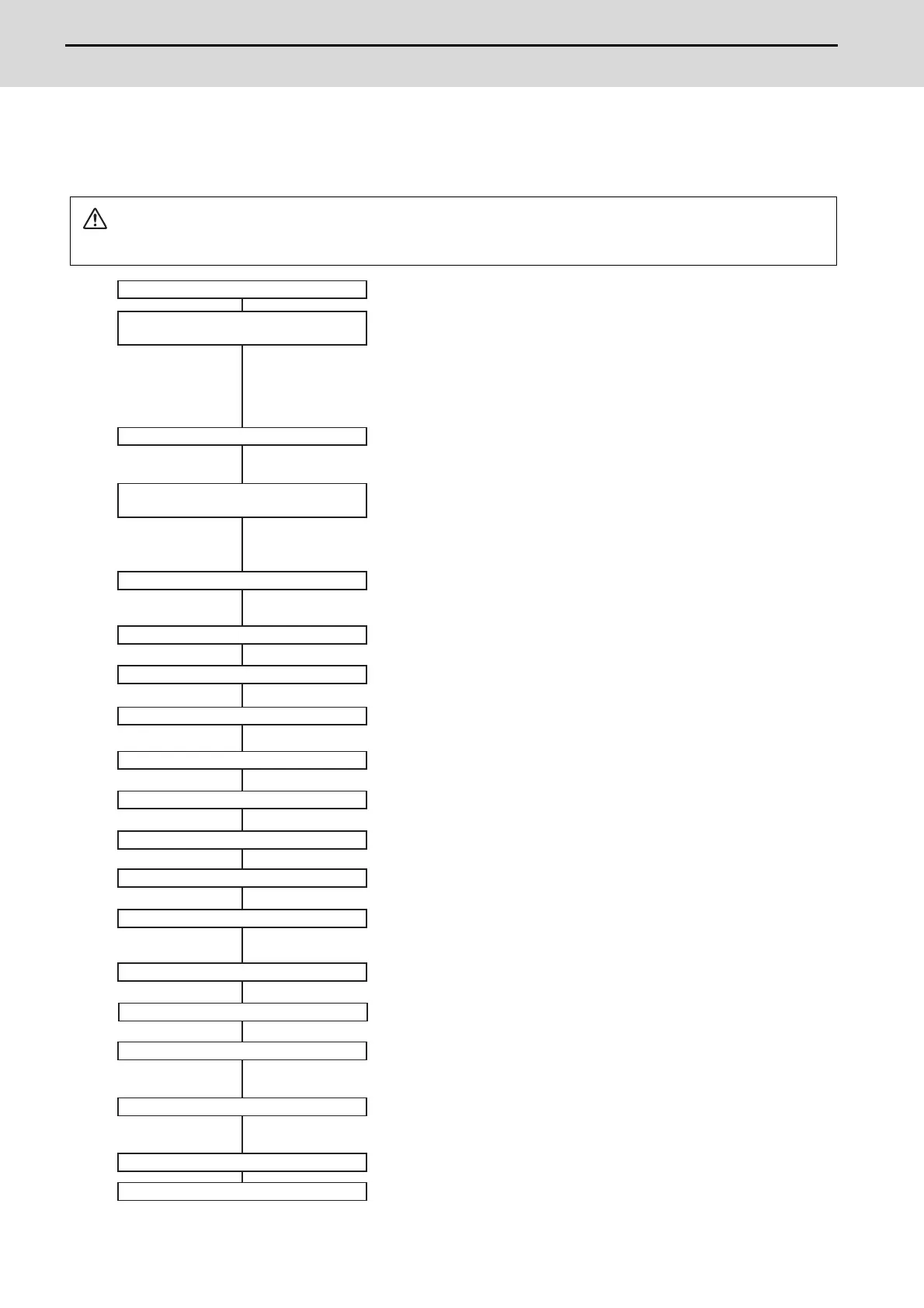

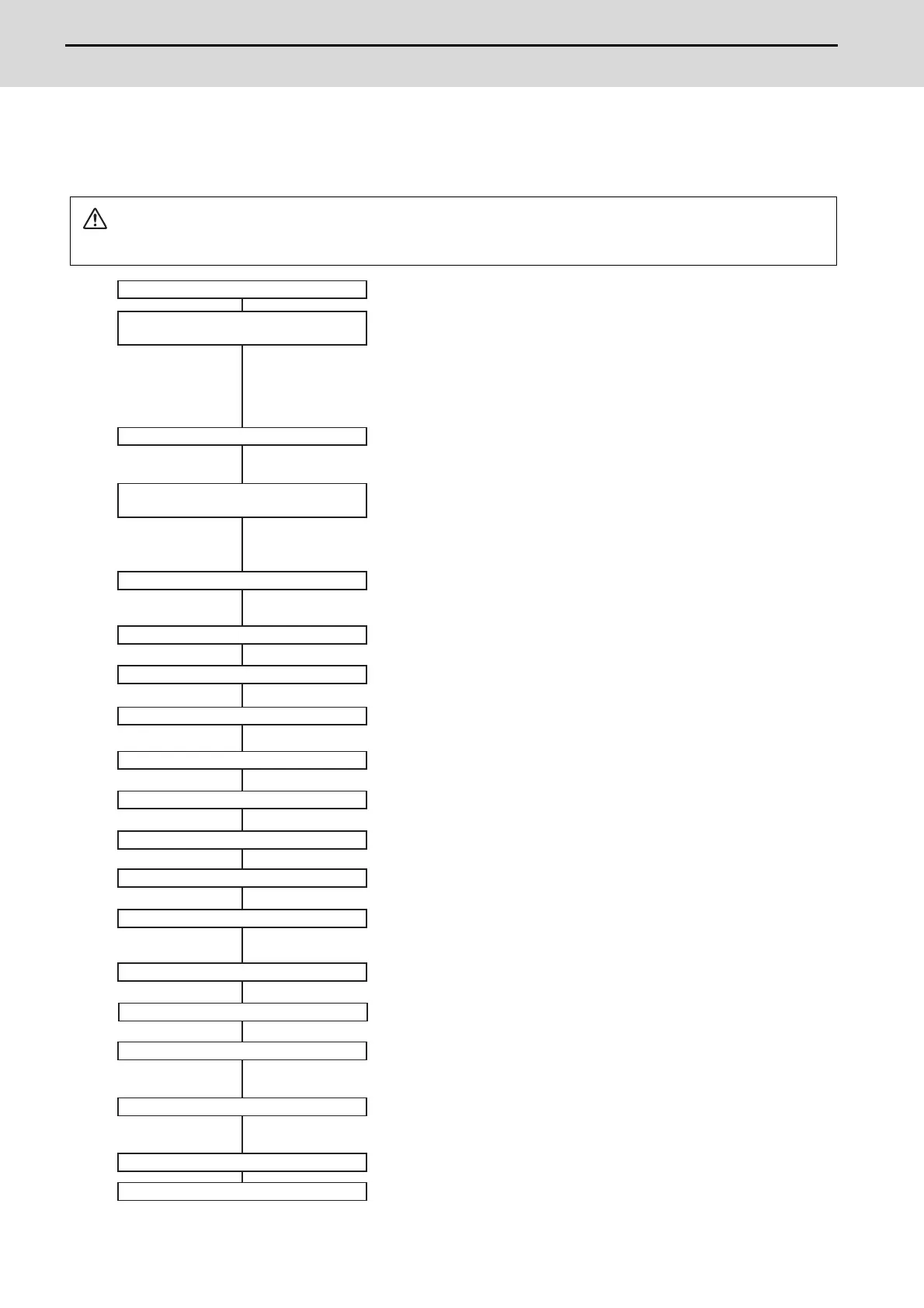

16.2 Flow of Initial Setup

The following flow chart shows the procedures of the initial setup.

(Note) When setting up with backup files, refer to the chapter of "Data Backup and Restoration".

WARNING

Do not cancel the emergency stop before confirming the basic operation.

Setting the machine parameters (1)

Formatting the NC memory

Setting the machine parameters (2)

Setting Date and Time

Refer to section 19.2

Refer to section 19.1 to 19.2

Refer to section 19.3

Refer to section 19.4

Selecting the NC system type and displayed language.

Setting the parameters for the system specifications.

Setting the parameters for the machine specifications.

Set the date and time on the integrated time screen.

Refer to section 17

Refer to section 18

Refer to section 20

Refer to section 21

Refer to section 22

Refer to section 27

Refer to the Instruction Manual

Refer to section 23

Points

Is the power supply within a specified range?

Is the power supply polarity correct?

Is the connection of the motor power cable and the encoder cable correct?

Is the grounding correct?

Carry out the connecting and setting of drive units, batteries and remote I/O units.

Initialize the NC Internal data (SRAM).

Write the created sequence program to NC's ROM using GX Developer or GX Works2.

Confirm input/output of signals, alarm display and manual operation.

Carry out the setting for establishing the reference position (zero point).

Set the tool entry prohibited range.

Confirm that the spindle operates properly in manual/MDI operation.

Confirm the spindle rotation speed as well.

Start

Confirming the connection between

control unit and peripheral devices

Connecting and Setting the Hardware

Sequence Program Writing

Confirming the Basic Operation

Setting the Position Detection System

Setting the Stored Stroke Limit

Confirming the Spindle Operation

Inputting the machining program

End

Setting Up with

M80/M800S SETUP INSTALLER

Refer to section 28

Input the customized data for the handy terminal.

(Note) This procedure is required only when connecting the handy terminal.

Install the custom data (G code guidance data),

start-up screen and user cycle.

If you do not need the installation, go to the next section.

Setting the Handy Terminal

Refer to section 24Setting the Machine Error Compensation

Refer to section 25

Set the position switches.

Setting the Position Switches

Refer to section 26

Set the backlash compensation and the backlash compensation II.

Setting the Backash Compensation

Set the memory-type pitch error compensation, the memory-type relative position error

compensation, and the bidirectional pitch error compensation.

Loading...

Loading...