M800S/M80/E80 Series Connection and Setup Manual

29 Setting the Deceleration Check

538

IB-1501269-J

29.6 Precautions

(1) When in-position check is valid, set the servo in-position width of the servo parameter.

(2) This function is invalid for the axes in the automatic machine lock.

(3) When the MSTB is commanded to the next block of the cutting commanded block, the MSTB code is output before

the completion of the cutting command deceleration. Confirm the DEN (motion command completion) signal with

PLC before the execution of the MSTB command which needs to be executed after the completion of the axis

movement.

(4) When the control axis in the synchronous/superimposition control exists in the part system for which in-position

check method has been set, the deceleration completion will be determined when the smoothing for all axes

reaches zero. (Same as the smoothing check method)

(5) When the thread cutting commands are issued consecutively, the deceleration check will not be performed at the

block joint.

(6) Deceleration check for opposite direction movement reversal

- When deceleration check is valid (G0Ipfg=1), deceleration check will be executed when the axis reverses its

movement to the opposite direction at the G1 -> G0 successive block regardless of whether G0 non-

interpolation is ON or OFF.

- When deceleration check is valid (G0Ipfg=1), deceleration check will be executed when the axis reverses its

movement to the opposite direction at the G1 -> G0 successive block even in the fixed cycle.

- In the G1 -> G28, G1 -> G29 or G1 -> G30 successive blocks, deceleration check will always be executed

when the G1 movement is completed, when movement to the intermediate point is completed and when

movement to the return point is completed. Note that if the base specification parameter's simple zero point

return "#1222 aux06/bit7" is valid, the base specification parameter G1 -> G0 deceleration check (G0Ipfg) will

be followed when the G1 movement is completed and when movement to the intermediate point is completed.

(Deceleration check will always be executed when movement to the return point is completed even in this

case.)

(7) Designating in-position width

- The in-position width (programmable in-position check width) designated in the machining program has a

priority over the in-position width set in the parameters (SV024, G0inps, G1inps).

- When error detect is ON, in-position check will be forcibly carried out.

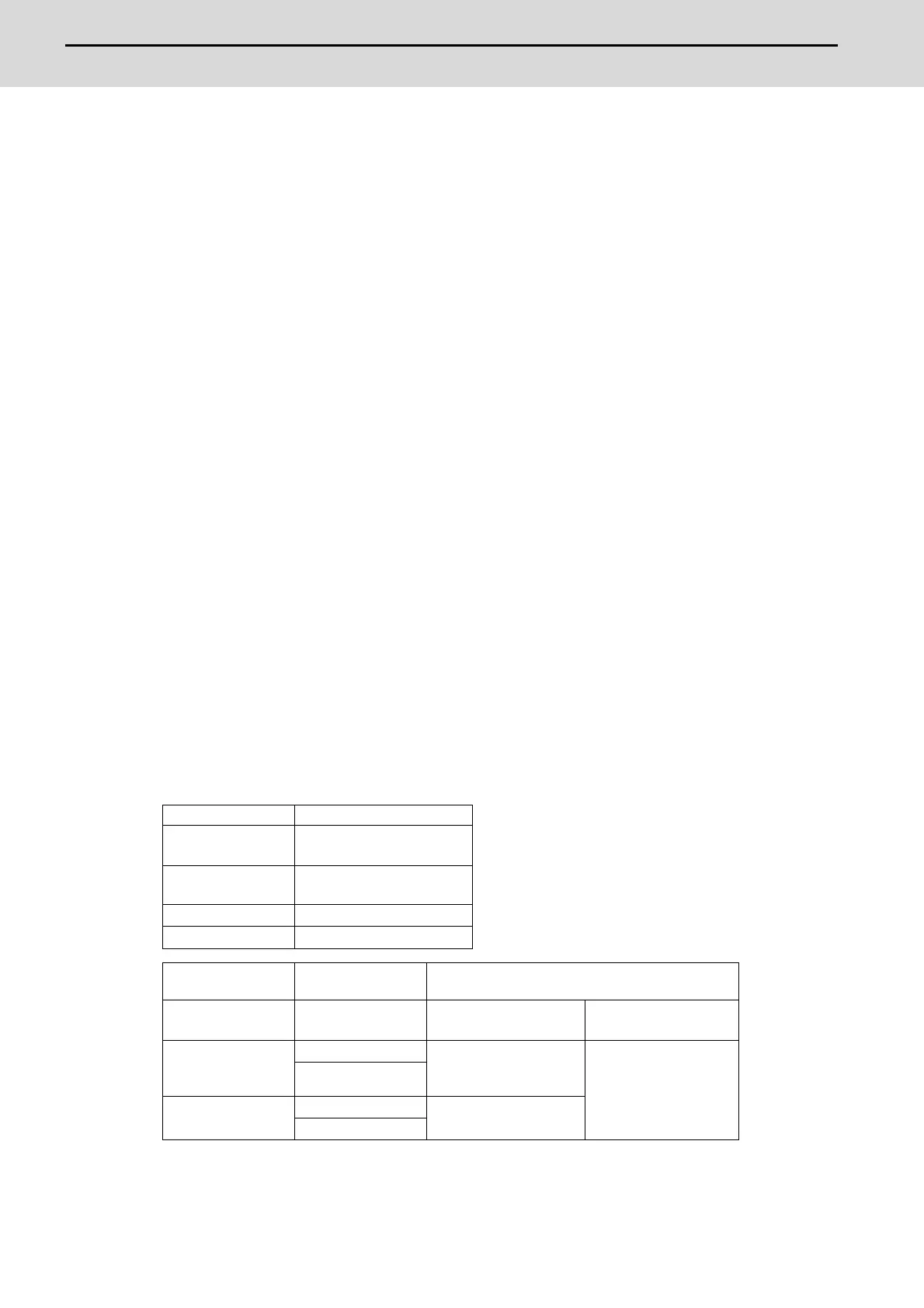

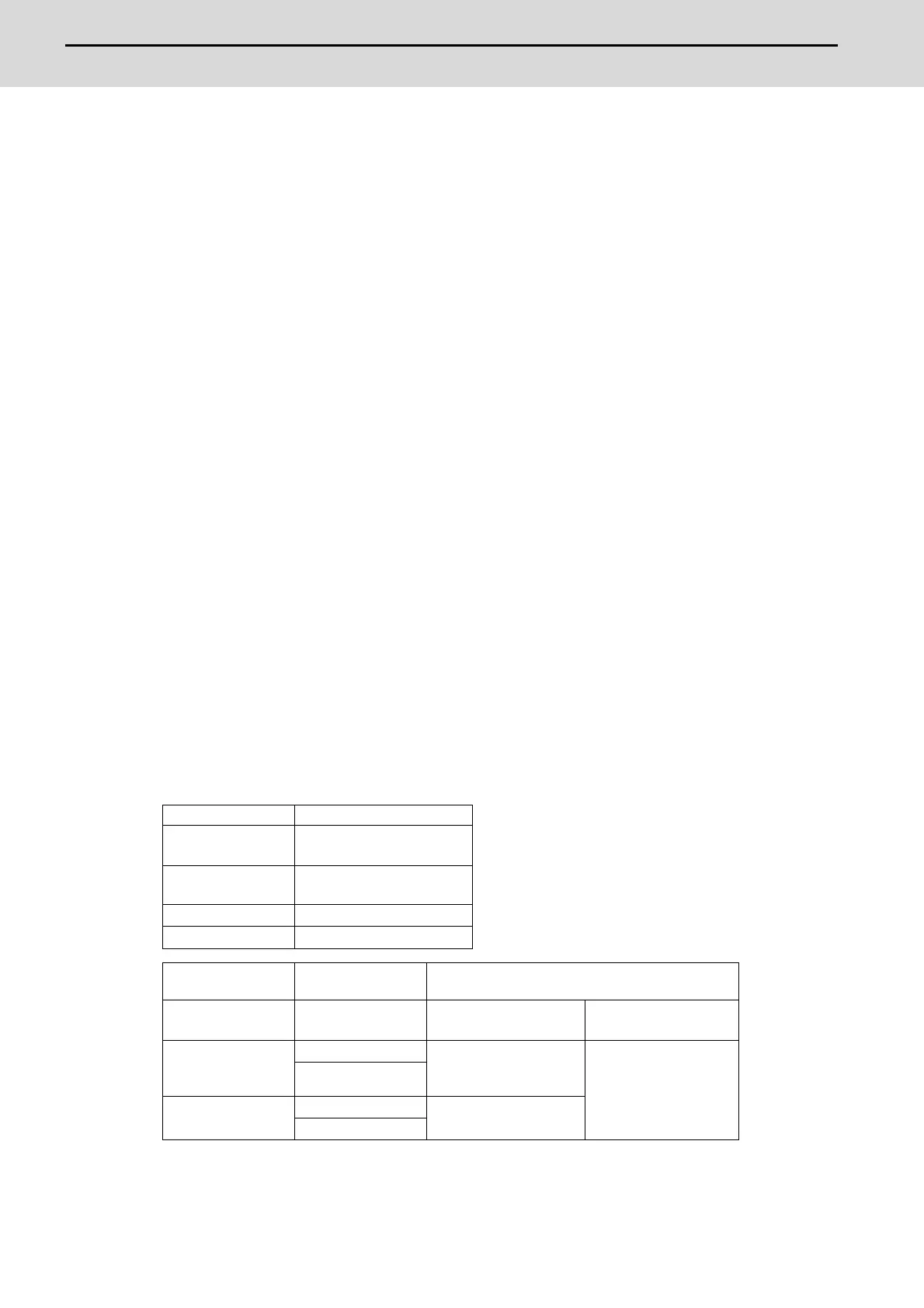

(8) Deceleration check in movement including spindle/C-axis

- The deceleration check for spindle/C-axis movement command is as described in the table below. That is

because a vibration and so on occurs in the machine when the position loop gain (#13002 PGN) is changed

during the axis movement.

(Note 1) When G1 command is issued, the in-position check is performed regardless of the deceleration

check parameter.

(Note 2) XX expresses all commands.

Parameter Rapid traverse command

Inpos(#1193)

G0 → XX

(G0+G9

→ XX)

0

Command

deceleration

check

1 In-position check

2 Smoothing check

Parameter Parameter

Other than rapid traverse command

(G1: other than G0 command)

G1SmthChk(#1389)

AUX07/BIT-1

(#1223/BIT-1)

G1 → G0

(G1+G9 → XX)

G1 → G1

0

0 In-position check

(Applicable only to

SV024)

No deceleration check

1

1

0

Smoothing check

1

Loading...

Loading...