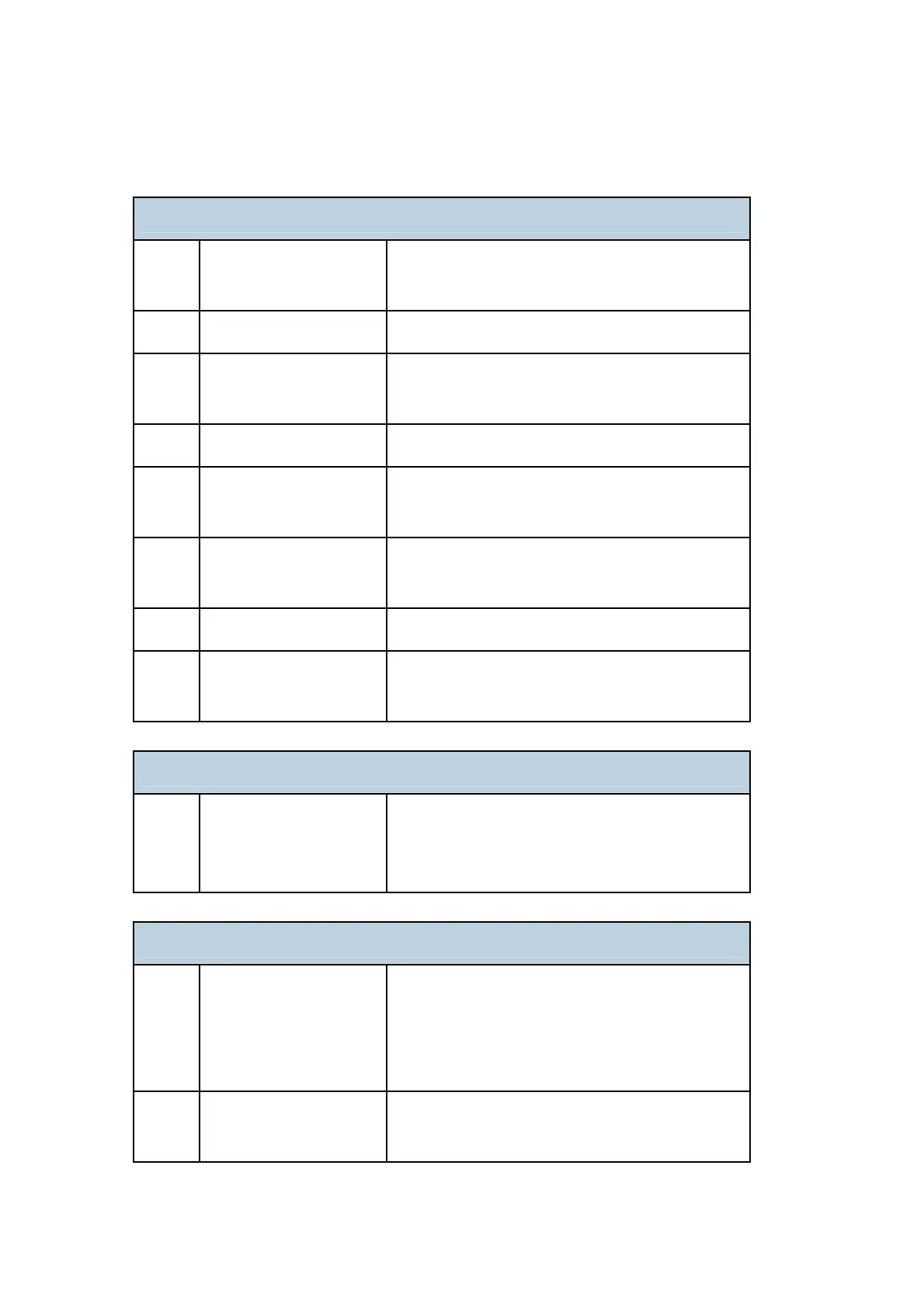

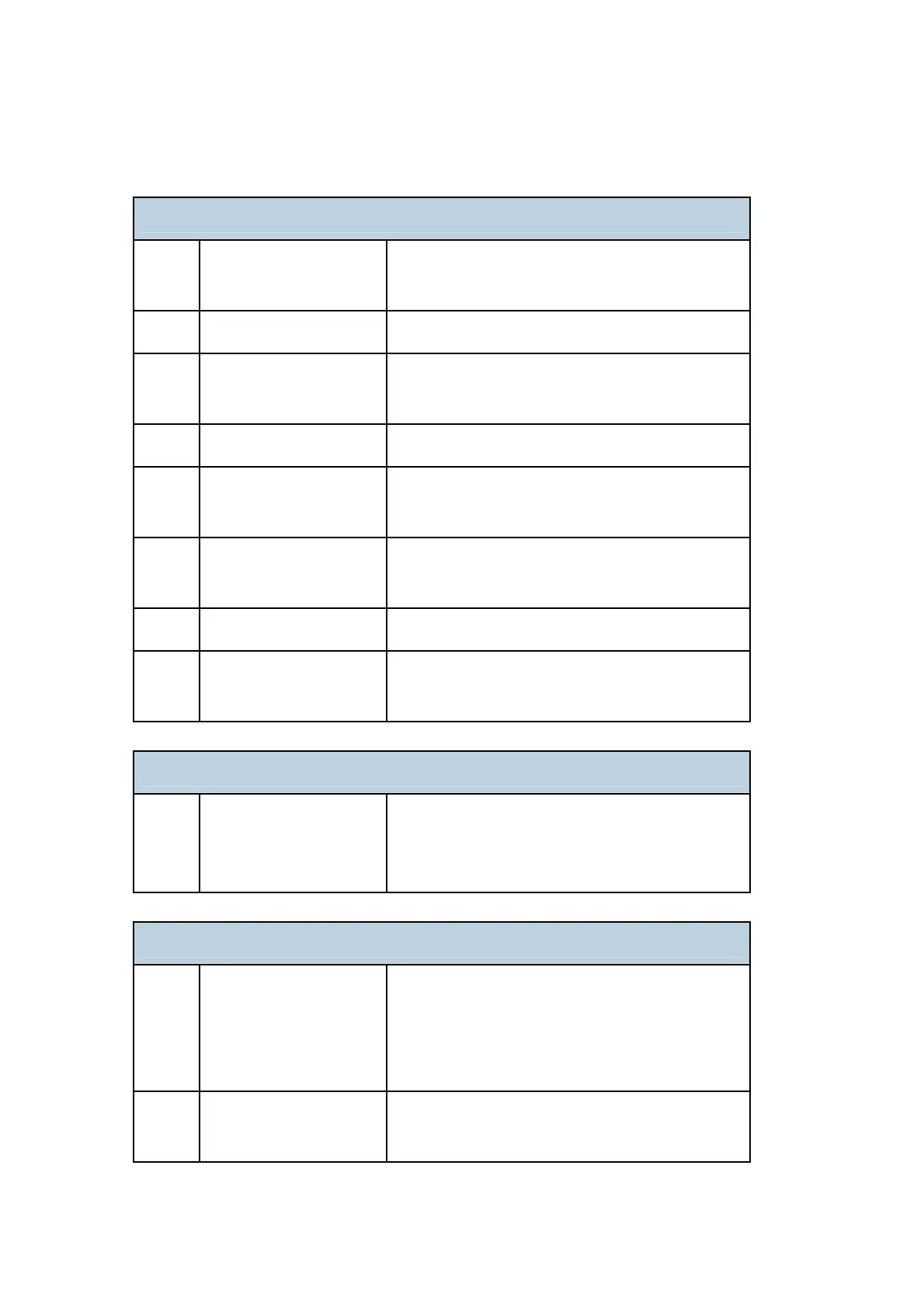

Electrical Components

D372 52 SM

2.7.2 SUMMARY OF ELECTRICAL COMPONENTS

Motors

M1 Feed-Out Belt Motor

Drives the two feed-out belts (1 pawl each). The

pawls push the finished stack out of the finisher.

M2 Front Fence Motor Moves the front fence to the back and front.

M3

Positioning Roller Arm

Motor

Lowers and raises the positioning roller arm and

positioning roller.

M4 Rear Fence Motor Moves the rear fence to the front and back.

M5

Stapler Movement

Motor

Moves the stapler to the front and back.

M6 Transport Motor

Drives all the rollers in the finisher: entrance

roller, positioning roller, return rollers, exit roller

M7 Tray Lift Motor Raises and lowers the output tray.

M8 Stapler Motor

The motor inside the stapler that drives staple

supply and stapling.

Board

PCB1 Main Board

Controls operation of the finisher. DIP switches

can be changed to adjust the positions of the

front and rear side fences.

Sensors

S1 Entrance Sensor

Detects the leading edge of the paper when it

enters the finisher. Readings of this sensor are

used for timing of finisher operation. Also detects

jams.

S

Feed Out Belt HP

Sensor

Detects the HP of the feed-out belt pawls on the

two feed-out belts (one pawl on each belt).

Loading...

Loading...