Development

D017/D018/D019/D020 6-46 SM

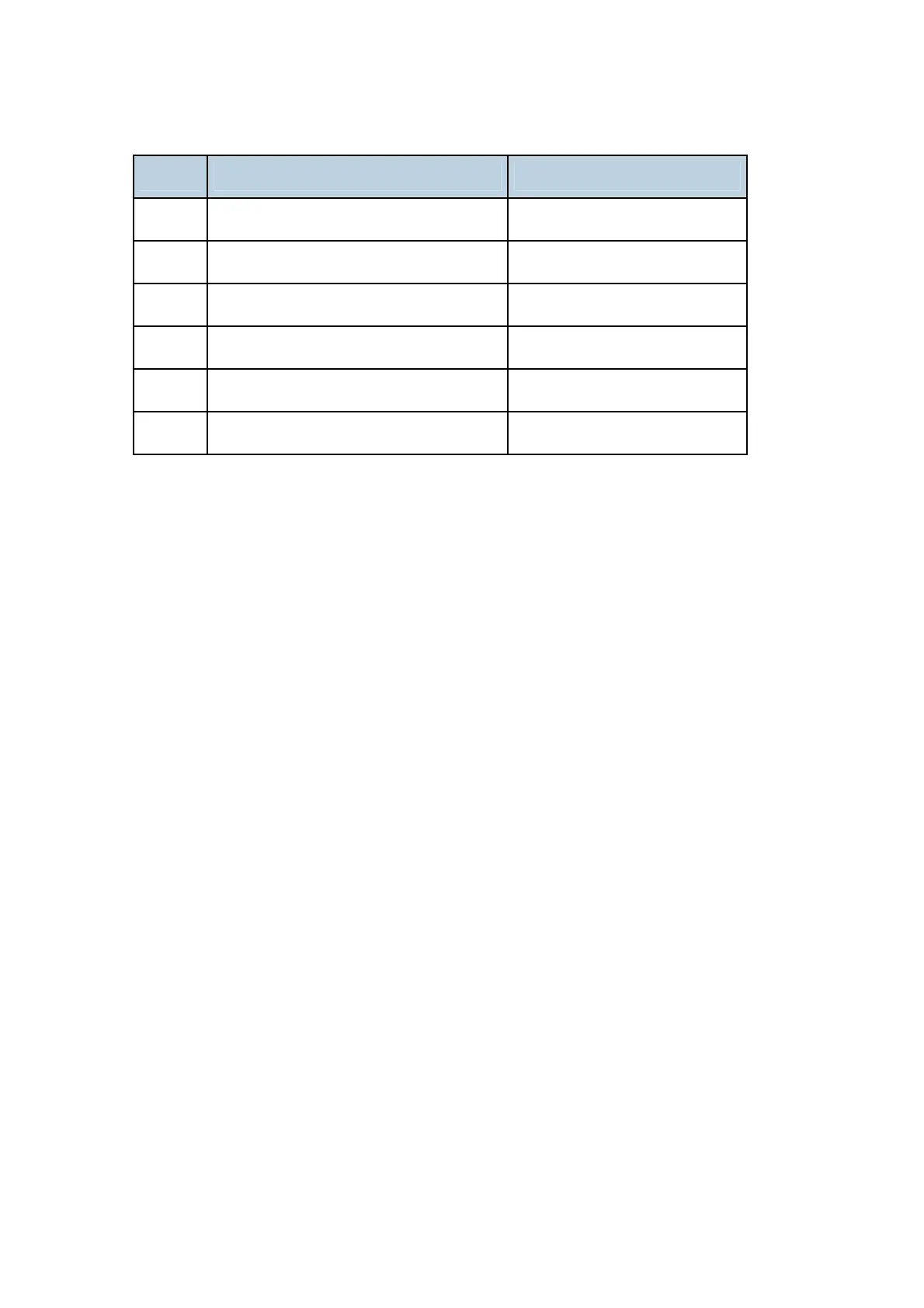

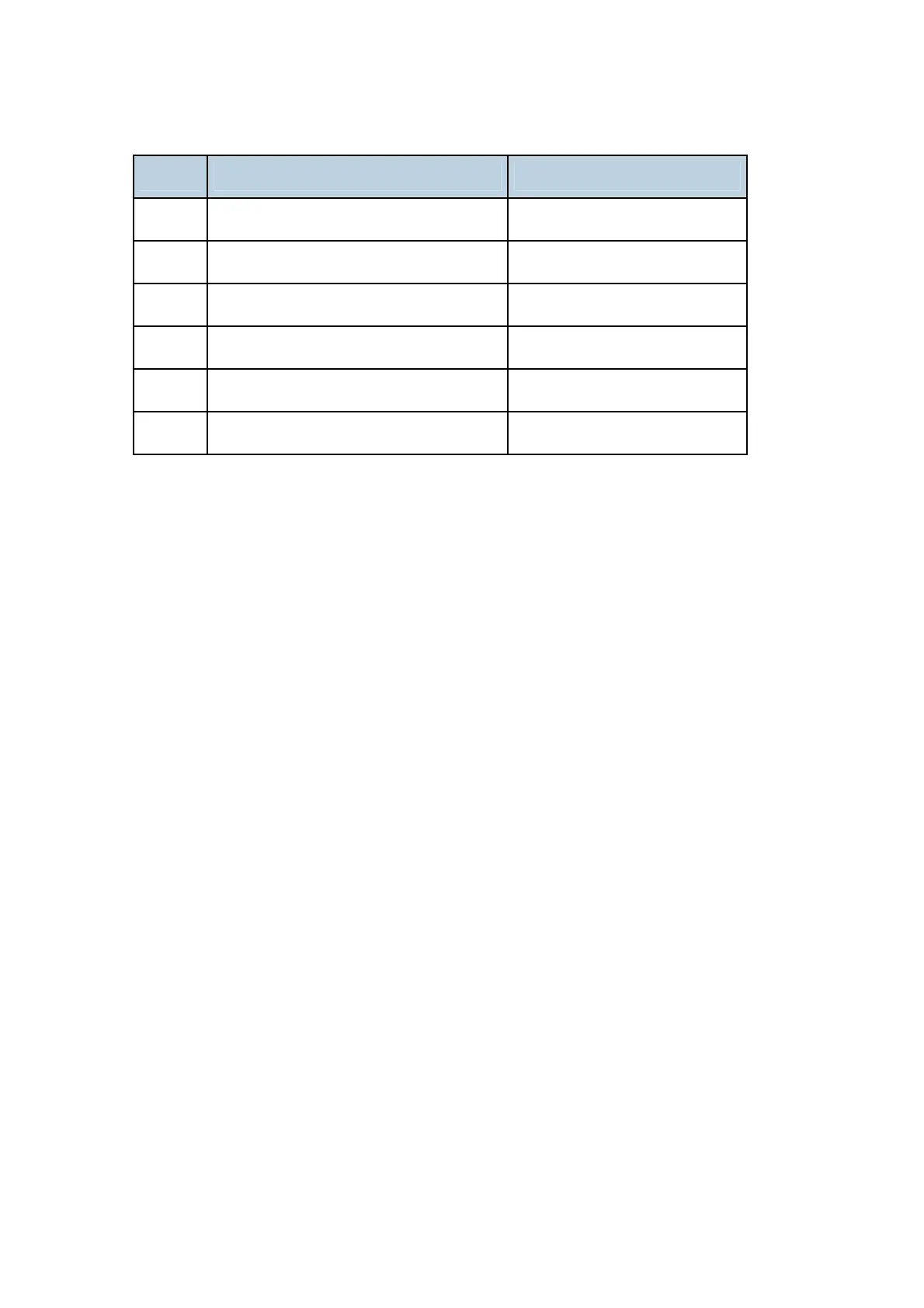

Level Decision Motor On Time (seconds)

2

S/16 <ΔVt < or = S/8

t x 2 (1.2)

3

S/8 <ΔVt < or = S/4

t x 4 (2.4)

4

S/4 <ΔVt < or = S/2

t x 8 (4.8)

5

S/2 <ΔVt < or = 4S/5

t x 16 (9.6)

6

4S/5 <ΔVt < or = S (near-end)

T (30); see note 3

7

S <ΔVt (toner end)

T (30); see note 3

The value of “t” can be changed using SP2-922 (default: 0.6 second)

The value of “T” can be changed using SP2-923 (default: 30 seconds)

T (30) means that toner is supplied intermittently in a half duty cycle (1.5 s on, 1.5 s off)

for 30 seconds

6.9.7 TONER SUPPLY IN ABNORMAL SENSOR CONDITIONS

ID sensor

Readings are abnormal if any of the following conditions occur:

Vsg < or = 2.5V

Vsg < 3.5V when maximum power (254) is applied

Vsp > or = 2.5V

(Vsg – Vsp) < 1.0V

ID sensor power required to make the standard output reaches the maximum value (254)

The above ID sensor values can be checked using SP2-220.

When this is detected, the machine changes the value of Vref to the previous value then

does the toner density control process (in a similar way to sensor control mode 2).

No SC code is generated if the ID sensor is defective.

TD Sensor

The TD sensor is checked every copy. If the readings from TD sensor become abnormal,

the machine changes the toner density control mode to fixed supply mode 2, and the toner

supply amount per page is always 200 ms, regardless of the value of SP2-925. Then at the

end of a job (if the optional fax unit is installed), or 100 copies after the TD sensor error was

detected (if no fax unit is installed), an SC code is generated (SC390) and the machine

must be repaired. The 100-copy threshold can be adjusted with SP 2-992.

Loading...

Loading...