Page 4-8 110XiIIIPlus Maintenance Manual 13185L-002 Rev. A 1/24/06

Section 4 Maintenance

Preventive Maintenance

Clean the Zebra Printer

Refer to Table 4-1 and perform the preventive maintenance procedures at the prescribed

interval.

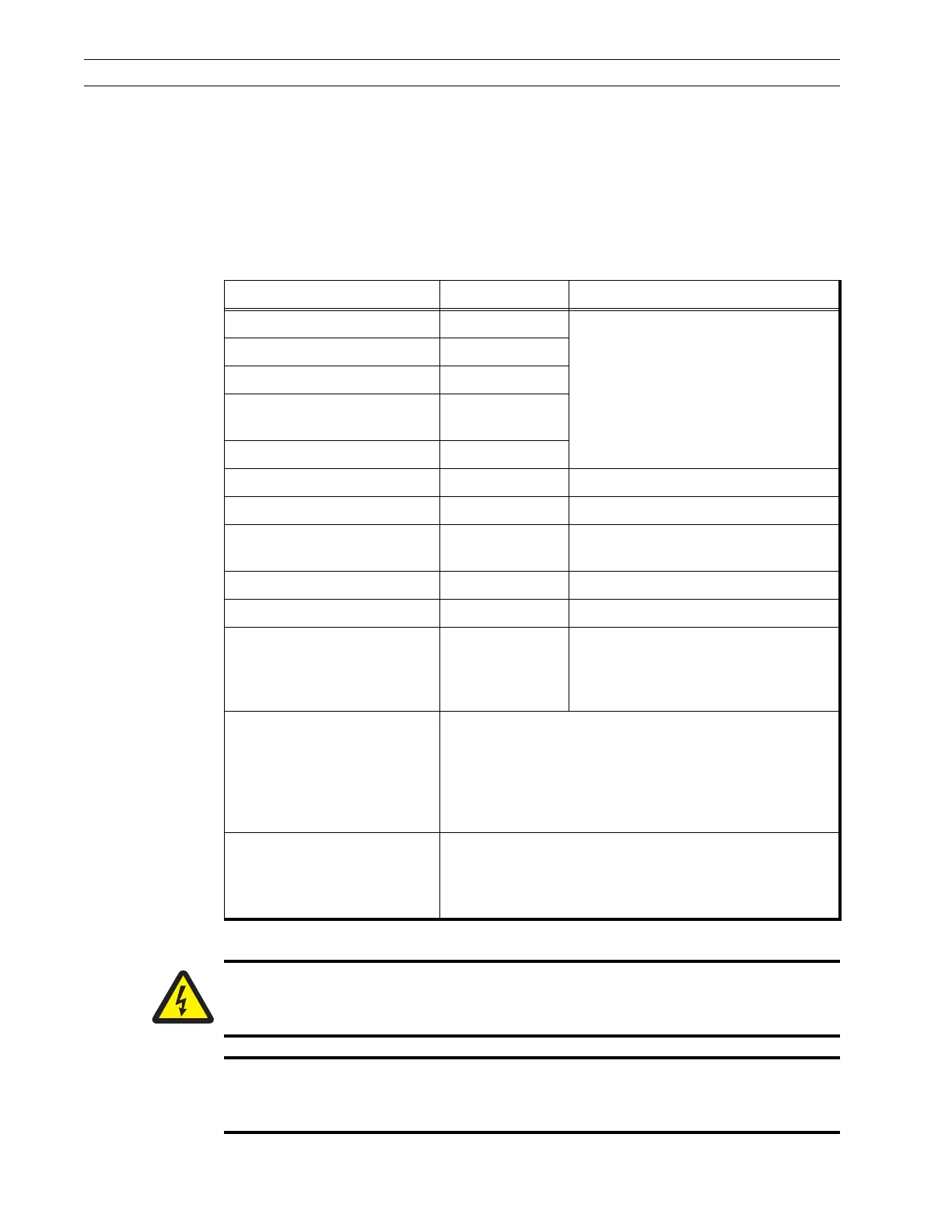

Table 4-1. Recommended Cleaning Schedule

Area Method Interval

Printhead Solvent* After every roll of media (or 500 feet

[150 m] of fanfold media) when

printing in Direct Thermal Mode and

after every roll of ribbon when printing

in Thermal Transfer Mode.

Platen Roller Solvent*

Transmissive Media Sensor Air blow

Reflective (Black-Mark)

Sensor

Air blow

Media Path Solvent*

Tear-Off or Peel-Off Bar Solvent* As needed.

Snap Plate Solvent* As needed.

Take-Label (Label-Available)

Sensors

Air blow Monthly.

Ribbon Sensor Air blow After every roll.

Ribbon Feeding Visual inspection After every roll.

Belts Visual

inspection:

Look for belt

wear.

Every 6 months or after every

500 rolls.

Media Supply Spindle

Media Take-Up Spindle

Ribbon Supply Spindle

Ribbon Take-Up Spindle

The spindle torque should be tested every year, or

500 rolls of media for the media take-up spindle; and

every 200 rolls of ribbon for the ribbon supply and ribbon

take-up spindles.

The spindle torque need not be readjusted unless the

printer is malfunctioning.

Cutter Clean stationary cutter blade with solvent* when it

becomes gummed up with adhesive and cut debris.

After cleaning, apply a small amount of grease to the

moving cutter parts.

*Zebra recommends a solution containing 90% isopropyl alcohol.

Caution:

Unless indicated otherwise, turn the printer power Off (O) and disconnect the

printer from the power source before performing the following maintenance.

Caution:

Use only the cleaning agents described in the following procedures. Zebra

Technologies will not be responsible if any other fluids are used on this printer.

Loading...

Loading...