Commissioning Manual

160 01/2017

Each scan (SM0.0) MCP_NCK (SBR37) Transferring MCP and HMI signals to

Each scan (SM0.0) HANDWHL (SBR39) Selecting a hand wheel through the

interface signal DB1900.DBB1xxx

Each scan (SM0.0) AXIS_CTL (SBR40) Coordinate enabling control, hardware

Note

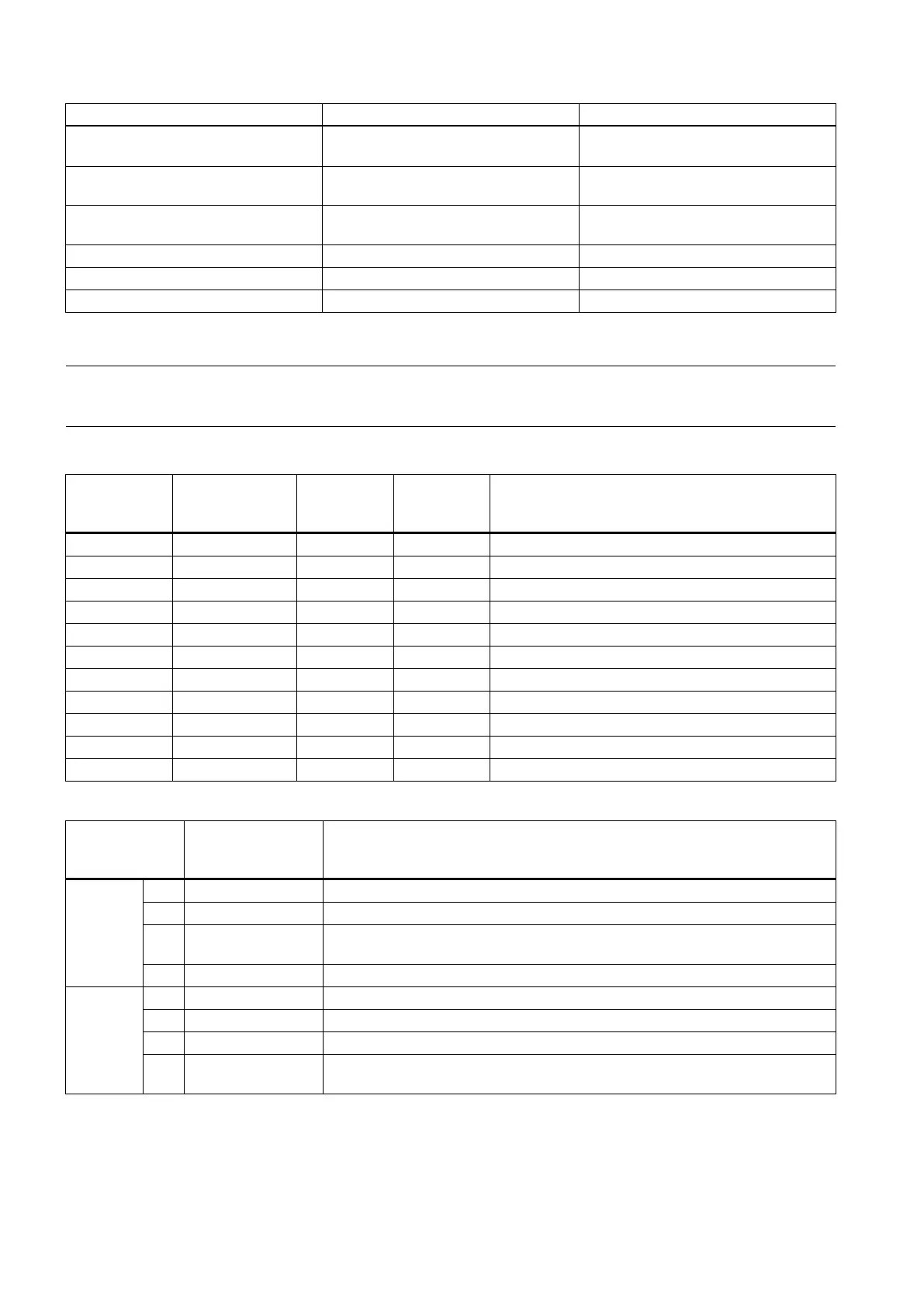

The following tables list

the PLC machine data used in the default PLC applications. The machine data not listed below is

reserved for the manufacturer.

USER_DATA_INT

MD14510

Machine data -

Integer

Layout of the traverse keys

Spindle override 50% key holding on time defined

Spindle override 100% key holding on time defined

Feedrate override 0% key holding on time defined

Feedrate override 100% key holding on time defined

14510[22] DB4500.DBW44 0.1 s 30 to 200 Monitoring time when searching for tools

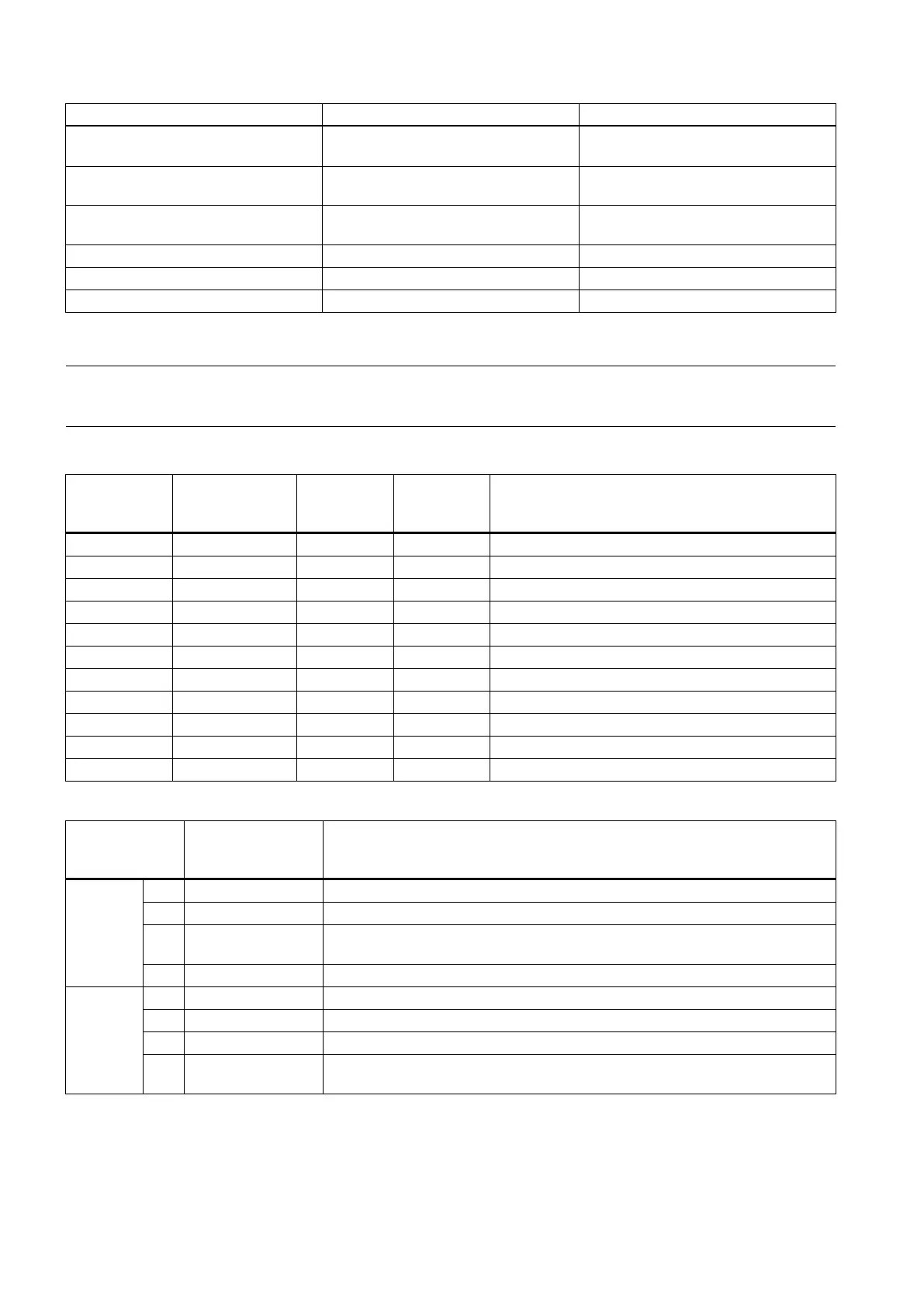

USER_DATA_HEX

MD14512

Machine data -

Hex

14512[16]

Function of chip conveyor (milling)

Function of safety door (milling)

Bit 3 DB4500.DBX1016.3 When the function of safety door is active, it can be triggered by M01/M02 (mill-

Handwheel assignment with the MCP/HMI

14512[17] Bit 0 DB4500.DBX1017.0 Turret (turning); tool magazine (milling)

Clamping function (turning)

Tail stock function (turning)

Bit 3 DB4500.DBX1017.3 Selection between handwheel and hand-held unit (0: handwheel; 1: hand-held

Loading...

Loading...