Creating a ShopTurn program

8.4 Fundamentals

Turning

Operating Manual, 01/2015, 6FC5398-8CP40-5BA2

245

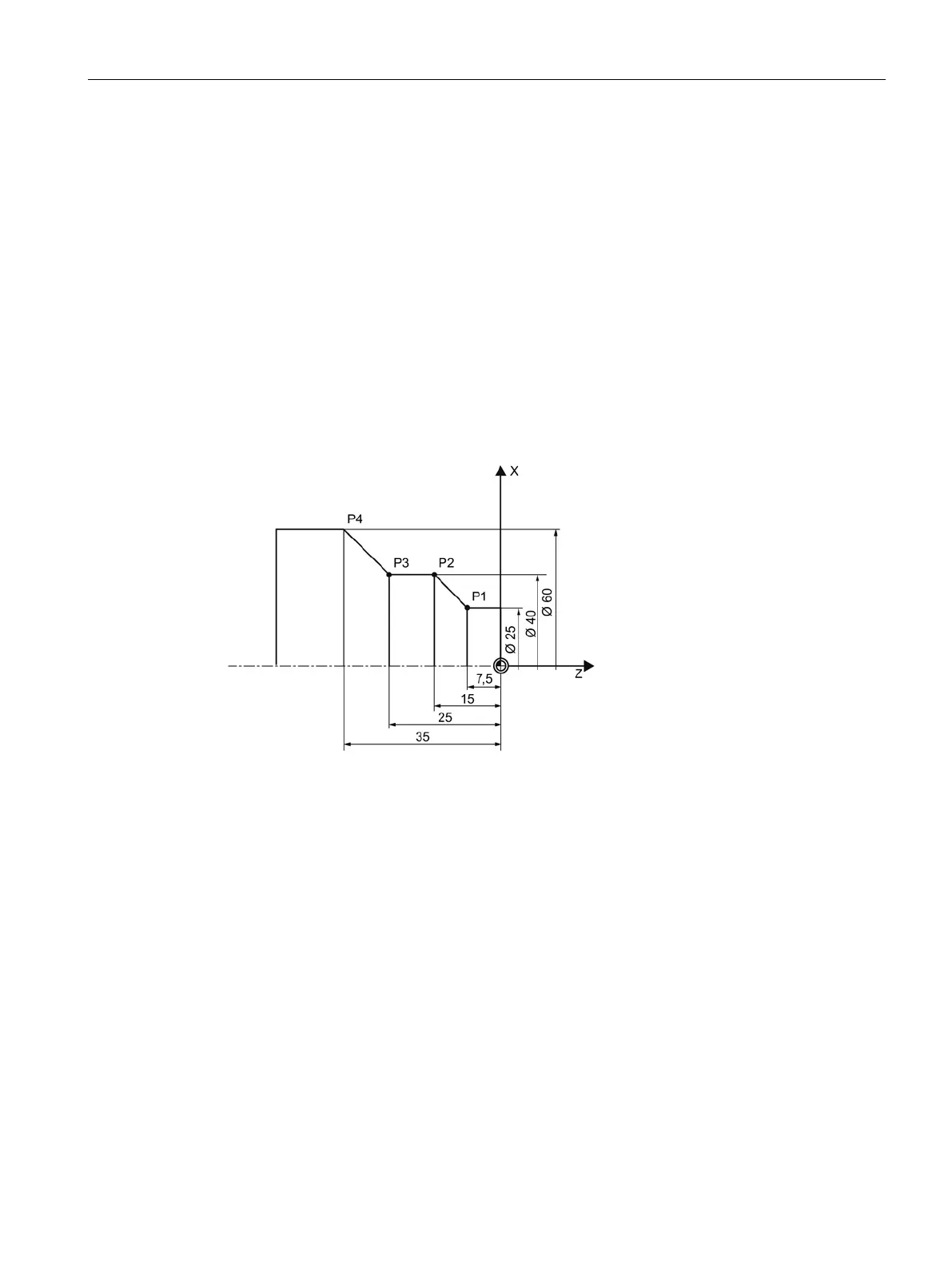

Absolute and incremental dimensions

When generating a machining step program, you can input positions in absolute or

incremental dimensions, depending on how the workpiece drawing is dimensioned.

You can also use a combination of absolute and incremental dimensions, i.e. one coordinate

as an absolute dimension and the other as an incremental dimension.

For the face axis (the X axis, in this case), in the machine data it is established whether the

diameter or radius is programmed in absolute or incremental dimensions.

Please refer to the machine manufacturer's specifications.

Absolute dimensions (ABS)

With absolute dimensions, all position specifications refer to the zero point of the active

coordinate system.

Figure 8-7 Absolute dimensions

The position specifications for the points P1 to P4 in absolute dimensions refer to the zero

point:

P1: X25 Z-7.5

P2: X40 Z-15

P3: X40 Z-25

P4: X60 Z-35