Machining the workpiece

5.8 Controlling the program run

Turning

Operating Manual, 01/2015, 6FC5398-8CP40-5BA2

139

Controlling the program run

5.8.1

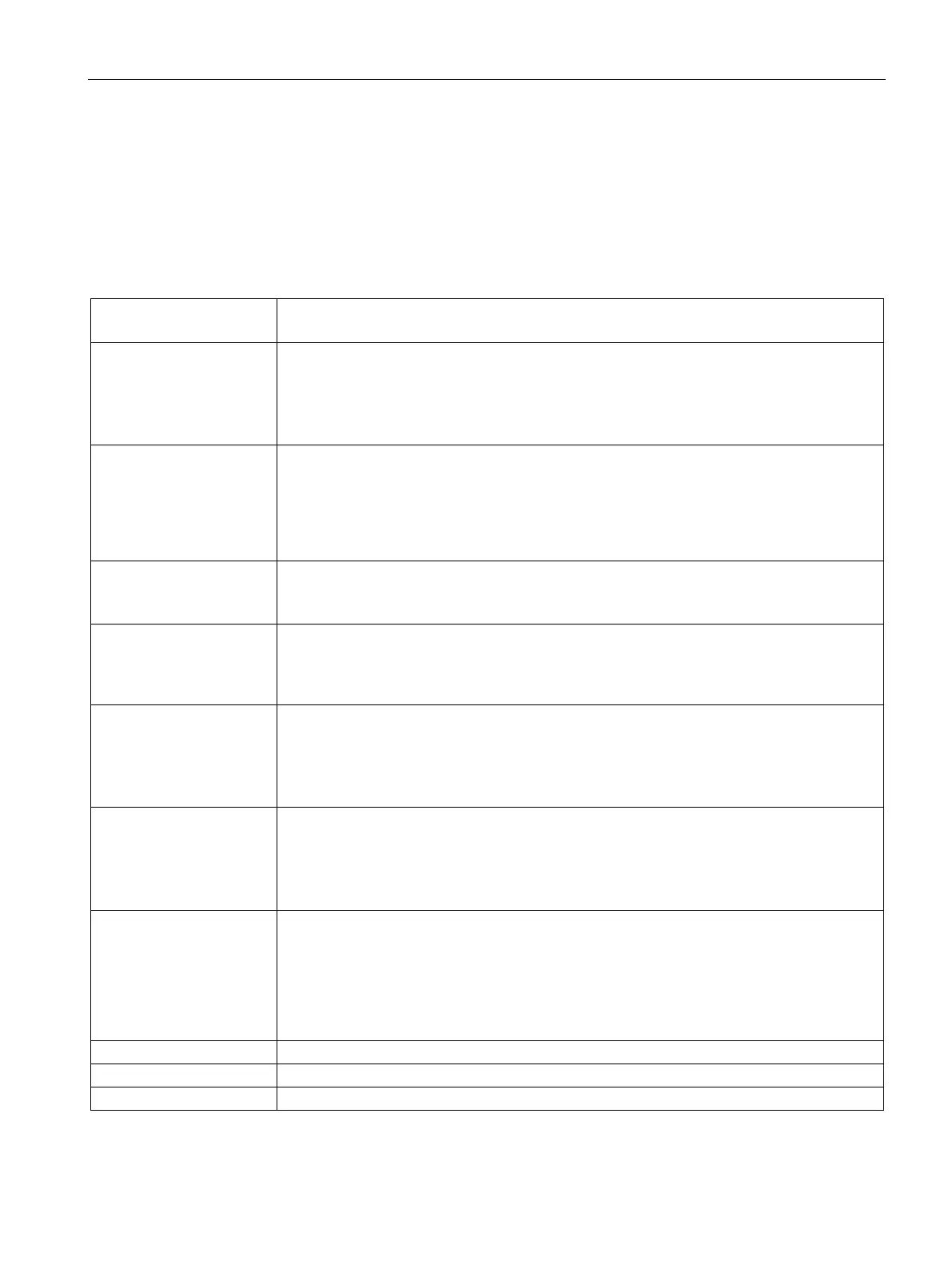

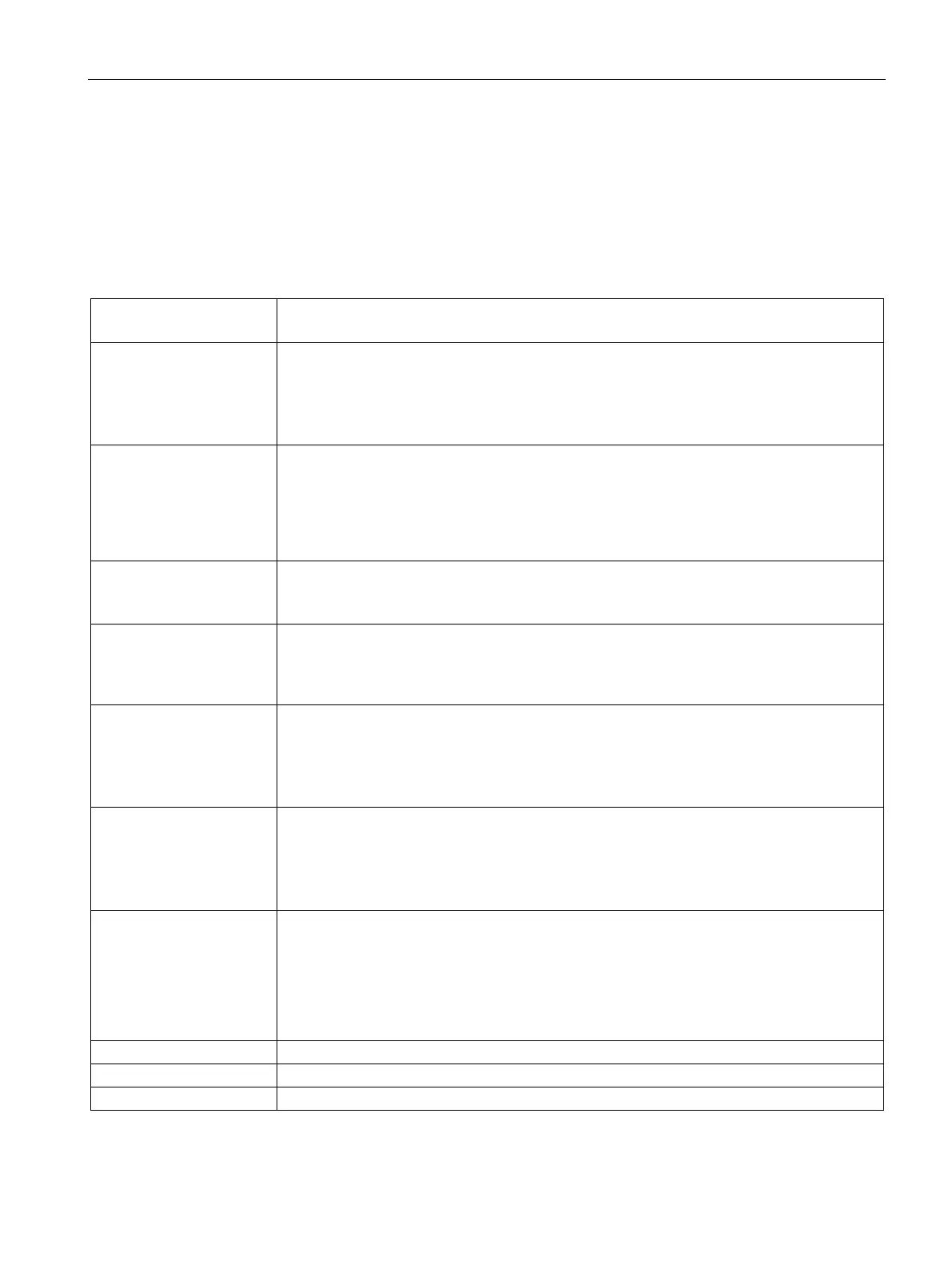

You can change the program sequence in the "AUTO" and "MDI" modes.

Abbreviation/program con-

trol

PRT

No axis motion

The program is started and executed with auxiliary function outputs and dwell times. In this

mode, the axes are not traversed.

The programmed axis positions and the auxiliary function outputs are controlled this way.

Note: Program processing without axis motion can also be activated with the function "Dry

DRY

Dry run feedrate

The traversing velocities programmed in conjunction with G1, G2, G3, CIP and CT are re-

placed by a defined dry run feedrate. The dry run feedrate also applies instead of the pro-

grammed revolutional feedrate.

Caution: Workpieces must not be machined when "Dry run feedrate" is active because the

altered feedrates might cause the permissible tool cutting rates to be exceeded and the

workpiece or machine tool could be damaged.

RG0

Reduced rapid traverse

In the rapid traverse mode, the traversing speed of the axes is reduced to the percentage

value entered in RG0.

Note: You define the reduced rapid traverse in the settings for automatic operation.

M01

Programmed stop 1

The processing of the program stops at every block in which supplementary function M01 is

programmed. In this way you can check the already obtained result during the processing of

a workpiece.

Note: In order to continue executing the program, press the <CYCLE START> key again.

Programmed stop 2

(e.g. M101)

The processing of the program stops at every block in which the "Cycle end" is programmed

(e.g. with M101).

Note: In order to continue executing the program, press the <CYCLE START> key again.

Note: The display can be changed. Please refer to the machine manufacturer's specifica-

DRF

Handwheel offset

Enables an additional incremental work offset while processing in automatic mode with an

electronic handwheel.

This function can be used to compensate for tool wear within a programmed block.

Note: You require the "Extended operator functions" option to use the handwheel offset (for

SB Individual blocks are configured as follows.

Single block, coarse: The program stops only after blocks which perform a machine function.

Data block: The program stops after each block.

Single block, fine: The program also stops only after blocks which perform a machine function

in cycles.

Select the desired setting using the <SELECT> key.

Skip blocks are skipped during machining.

When executing a jobshop program, it is converted into a G-code program.

In the program, the measurement results screen display is activated while machining.

Loading...

Loading...