PERIODIC MAINTENANCE

3-9

Example:

Valve pad number = 158

Rounded value = 160

New valve pad number = 160

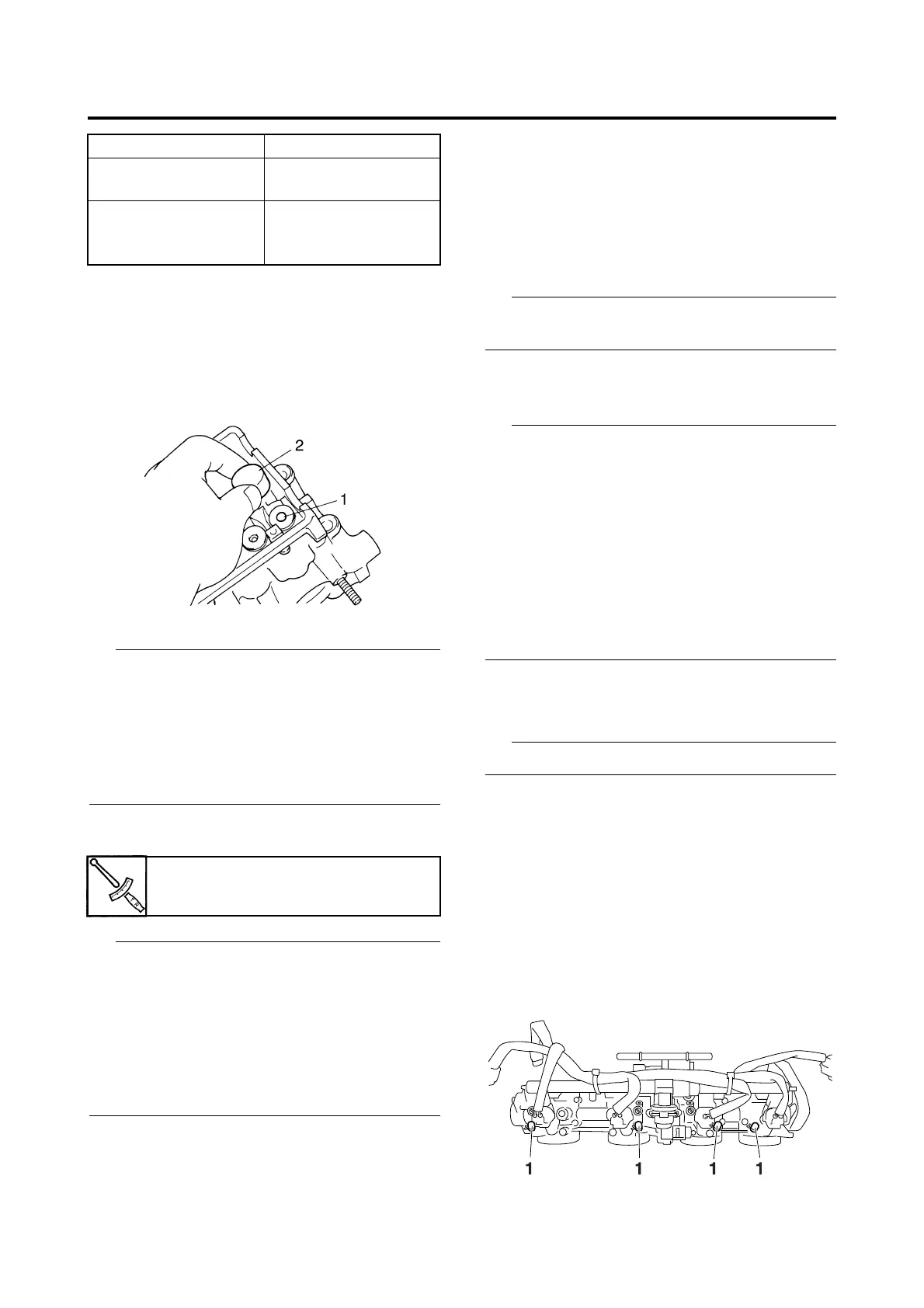

f. Install the new valve pad “1” and the valve

lifter “2”.

• Lubricate the valve pad with molybdenum

disulfide oil.

• Lubricate the valve lifter with engine oil.

• The valve lifter must turn smoothly when

rotated by finger.

• Install the valve lifter and the valve pad in the

correct place.

g. Install the exhaust and intake camshafts,

timing chain and camshaft caps.

• Refer to “CAMSHAFTS” on page 5-13.

• Lubricate the camshaft lobes and camshaft

journals.

• First, install the exhaust camshaft.

• Align the camshaft sprocket marks with the

camshaft cylinder head surface.

• Turn the crankshaft counterclockwise several

full turns to seat the parts.

h. Measure the valve clearance again.

i. If the valve clearance is still out of specifi-

cation, repeat all of the valve clearance

adjustment steps until the specified clear-

ance is obtained.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

7. Install:

• All removed parts

For installation, reverse the removal proce-

dure.

EAS20571

SYNCHRONIZING THE THROTTLE BODIES

Before synchronizing the throttle bodies, check

the following items:

• Valve clearance

• Spark plugs

• Air filter element

• Throttle body joints

• Fuel hoses

• Air induction system

• Exhaust system

• Breather hoses

• Vacuum hose

Checking the throttle body synchronization

1. Stand the vehicle on a level surface.

Place the vehicle on a suitable stand.

2. Remove:

• Rider seat

Refer to “GENERAL CHASSIS” on page

4-1.

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

• Air filter case

Refer to “AIR FILTER CASE” on page 7-

5.

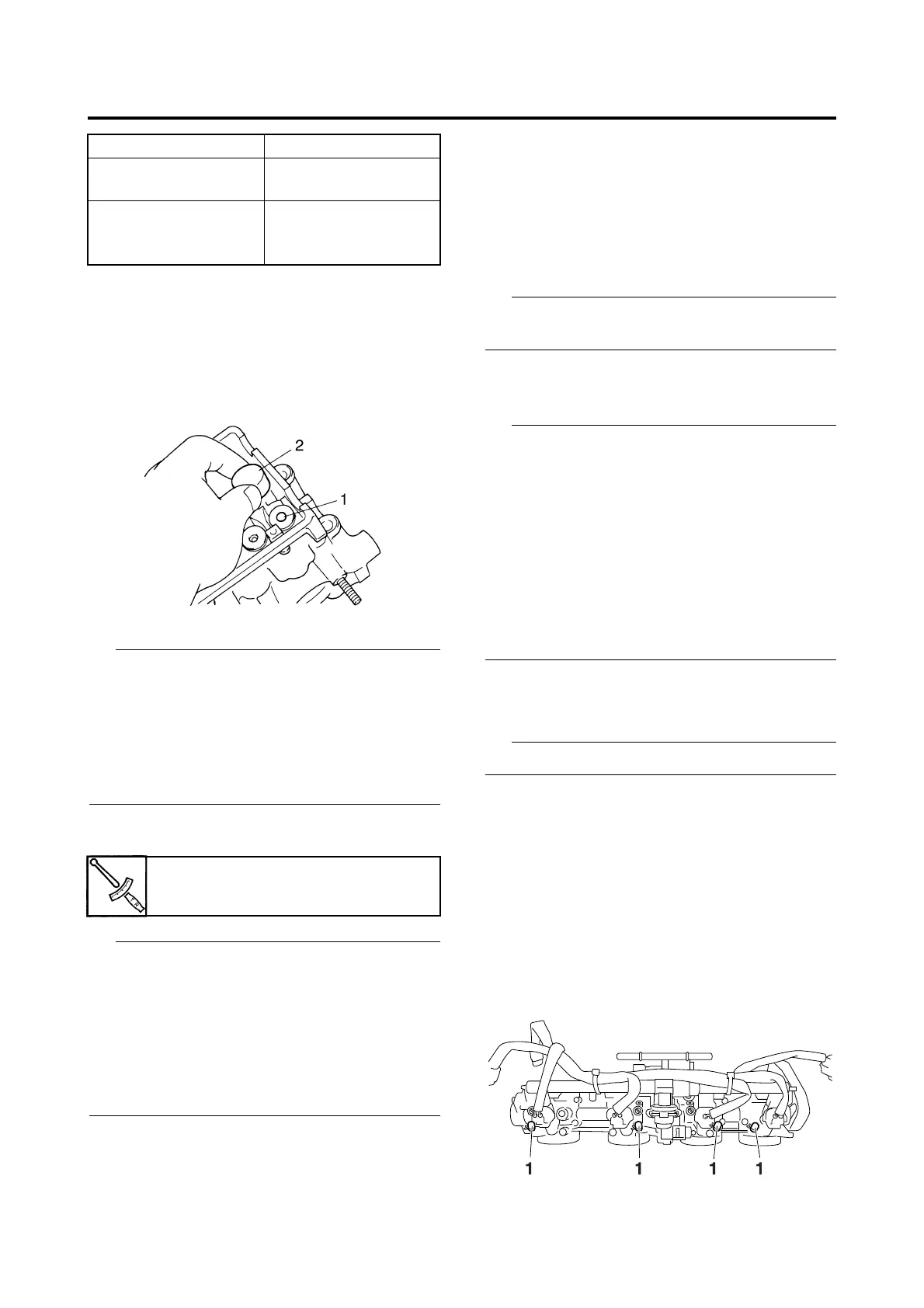

3. Remove:

•Caps “1”

Valve pad range No. 160–240

Valve pad thickness

1.60–2.40 mm

(0.0630–0.0945 in)

Available valve pads

17 thicknesses in

0.05 mm (0.0022 in)

increments

Camshaft cap bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Loading...

Loading...