CRANKSHAFT

5-89

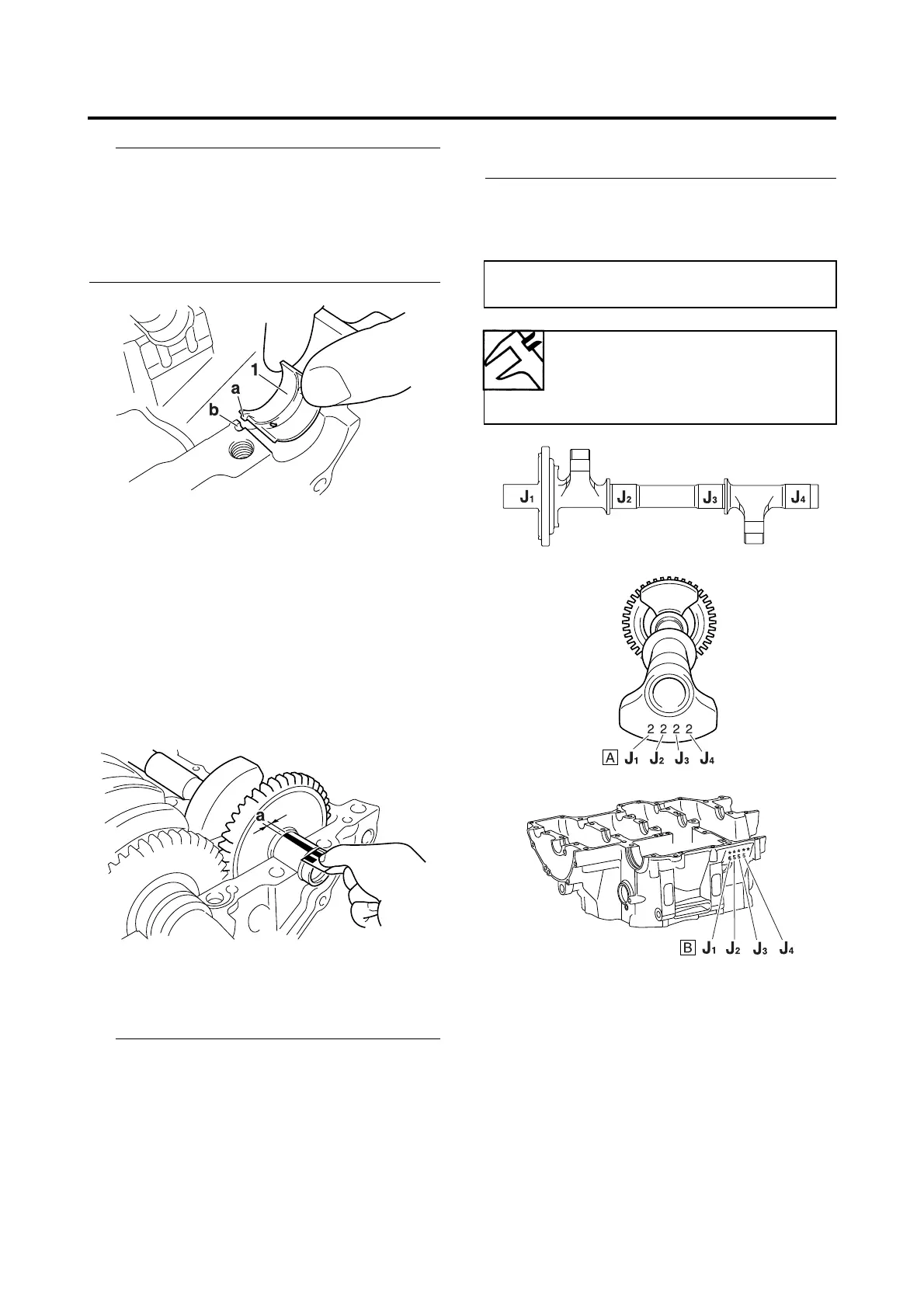

• Align the projections “a” of the balancer shaft

journal lower bearings with the notches “b” in

the lower crankcase.

• Do not move the balancer shaft until the

clearance measurement has been com-

pleted.

f. Tighten the bolts to specification in the

tightening sequence cast on the crankcase.

Refer to “CRANKCASE” on page 5-70.

g. Remove the lower crankcase and the bal-

ancer shaft journal lower bearings.

h. Measure the compressed Plastigauge®

width “a” on each balancer shaft journal.

If the balancer shaft-journal-to-balancer

shaft-journal-bearing clearance is out of

specification, select replacement balancer

shaft journal bearings.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

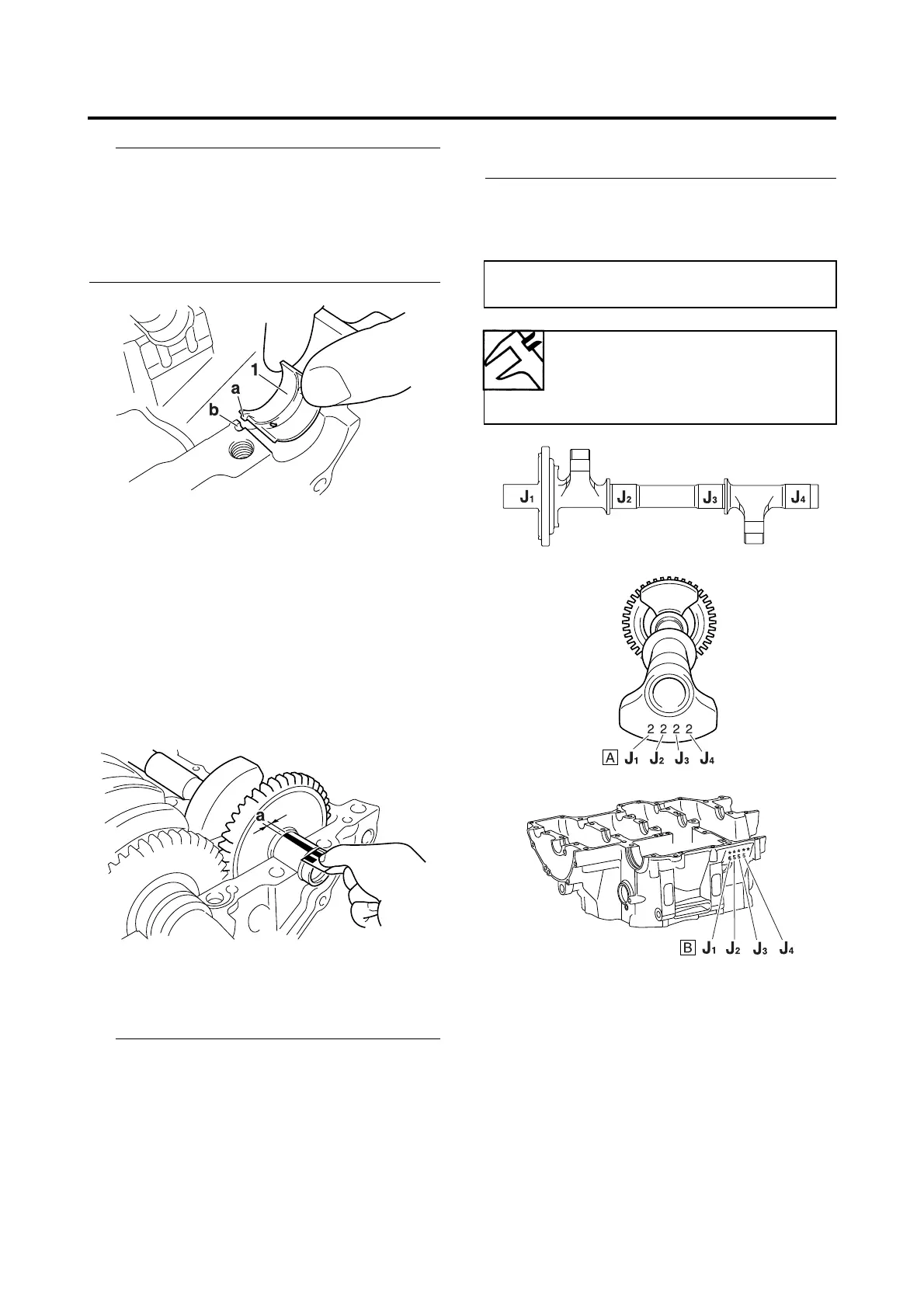

4. Select:

• Balancer shaft journal bearings (J

1

–J

4

)

• The numbers “A” stamped into the balancer

shaft web and the numbers “B” stamped into

the lower crankcase are used to determine

the replacement balancer shaft journal bear-

ing sizes.

•J

1

–J

4

refer to the bearings shown in the bal-

ancer shaft illustration.

• If J

1

–J

4

are the same, use the same size for

all of the bearings.

For example, if the crankcase J

1

and bal-

ancer shaft web J

1

numbers are 6 and 2

respectively, then the bearing size for J

1

is:

EAS26200

INSTALLING THE CRANKSHAFT

1. Install:

• Crankshaft journal upper bearings

(into the upper crankcase)

• Crankshaft journal lower bearings

(into the lower crankcase)

• Crankshaft

J

1

(crankcase) - J

1

(balancer shaft web) - 1 =

6 - 2 - 1 = 3 (brown)

Bearing color code

0.White 1.Blue 2.Black

3.Brown 4.Green 5.Yellow

6.Pink

Loading...

Loading...