OIL PUMP

5-53

EAS24930

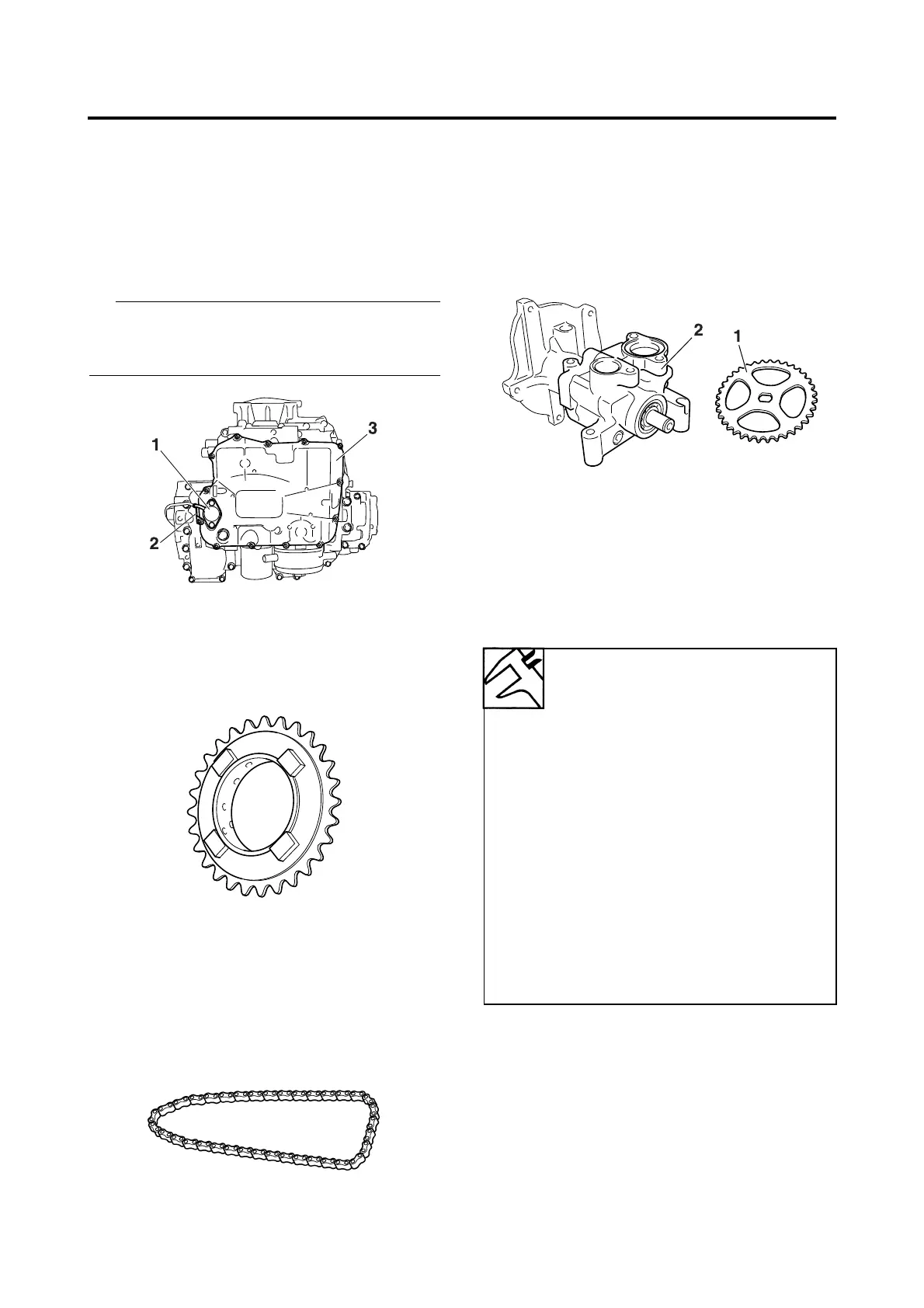

REMOVING THE OIL PAN

1. Remove:

• Oil level switch “1”

• Oil level switch lead holder “2”

• Oil pan “3”

•Gasket

• Dowel pins

Loosen each bolt 1/4 of a turn at a time, in

stages and in a crisscross pattern. After all of

the bolts are fully loosened, remove them.

EAS14B1021

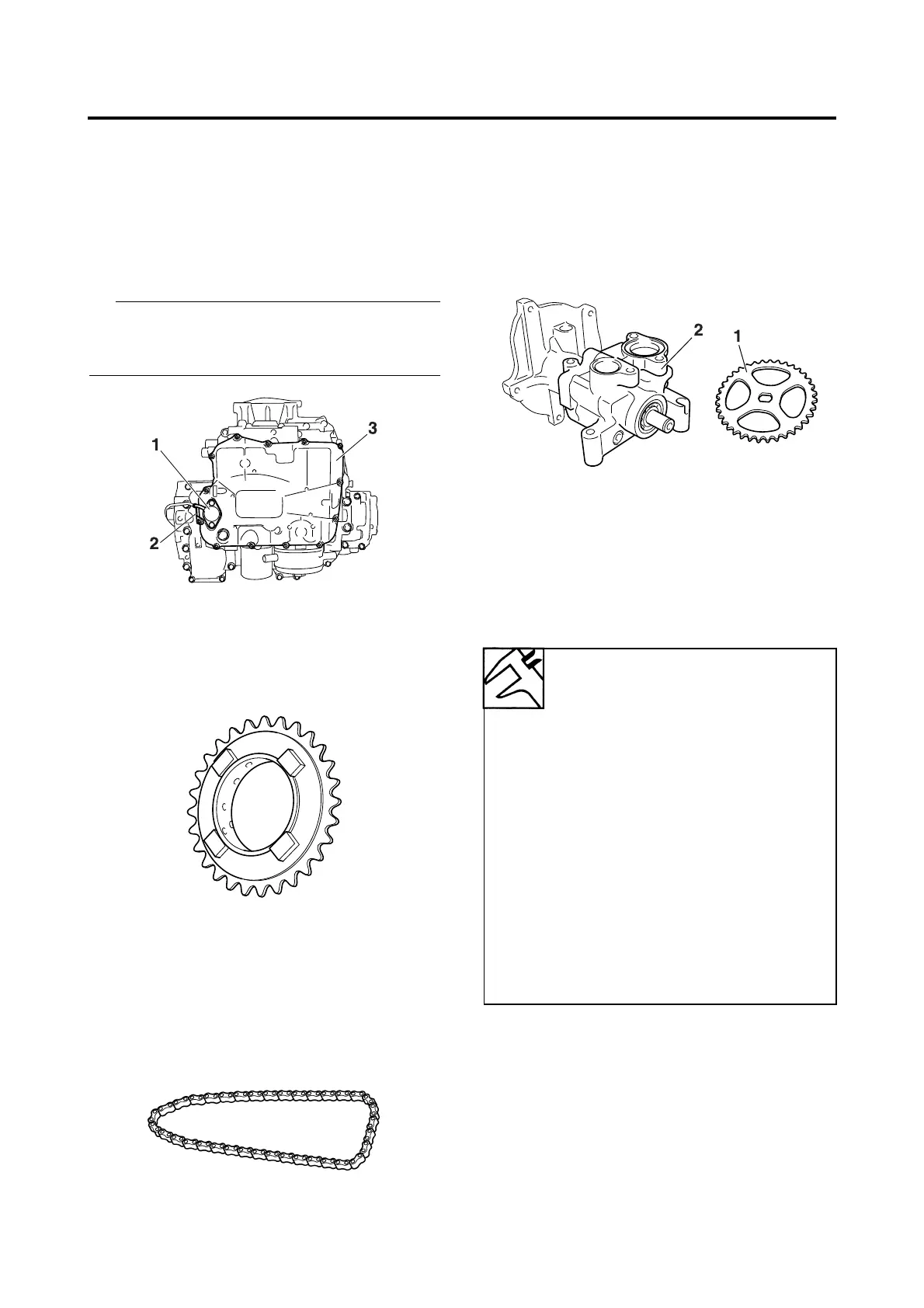

CHECKING THE SPROCKET AND CHAIN

1. Check:

• Oil/water pump assembly drive sprocket

Cracks/damage/wear → Replace.

2. Check:

• Oil/water pump assembly drive chain

Damage/stiffness → Replace the oil/

water pump assembly drive chain and oil/

water pump assembly drive sprocket as a

set.

EAS24960

CHECKING THE OIL PUMP

1. Check:

• Oil pump driven gear “1”

Cracks/damage/wear → Replace.

• Oil pump housing “2”

Cracks/damage/wear → Replace the oil/

water pump assembly.

2. Measure:

• Inner-rotor-to-outer-rotor-tip clearance “a”

• Outer-rotor-to-oil-pump-housing clear-

ance “b”

• Oil-pump-housing-to-inner-rotor-and-

outer-rotor clearance “c”

Out of specification → Replace the oil/

water pump assembly.

Inner-rotor-to-outer-rotor-tip

clearance

Less than 0.12 mm (0.0047 in)

Limit

0.20 mm (0.0079 in)

Outer-rotor-to-oil-pump-hous-

ing clearance

0.090–0.190 mm (0.0035–

0.0075 in)

Limit

0.260 mm (0.0102 in)

Oil-pump-housing-to-inner-and-

outer-rotor clearance

0.06–0.13 mm (0.0024–0.0051

in)

Limit

0.200 mm (0.0079 in)

Loading...

Loading...