422 ZXP Series 9 Card Printer Service Manual P1086708-001

Magnetic Card Encoder

Magnetic Encoding Type

AAMVA

The data stored on magnetic stripes on American driver’s licenses is specied by the American

Association of Motor Vehicle Administrators (AAMVA).

Alpha-numeric characters on Tracks 1 and 3, numerals only on Track 2.

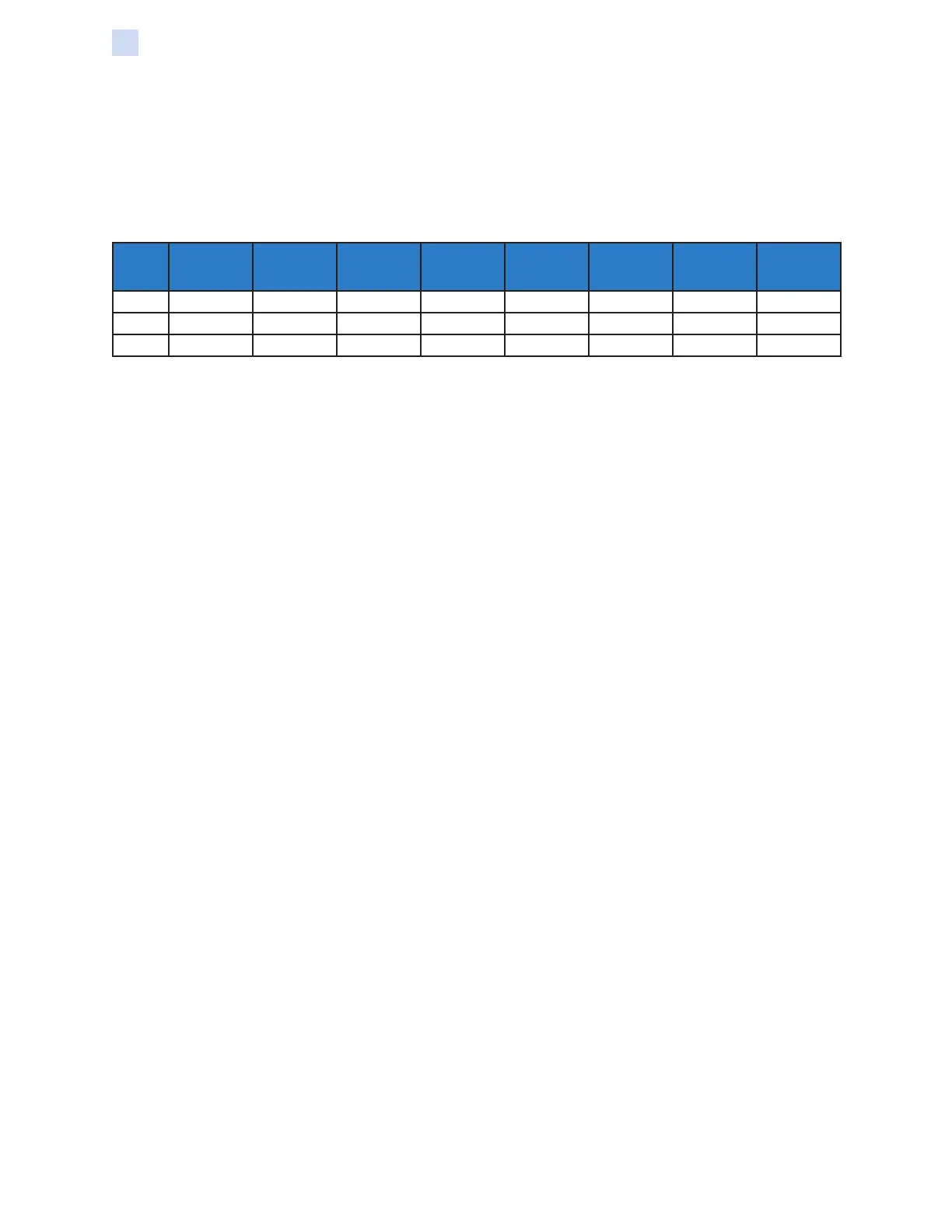

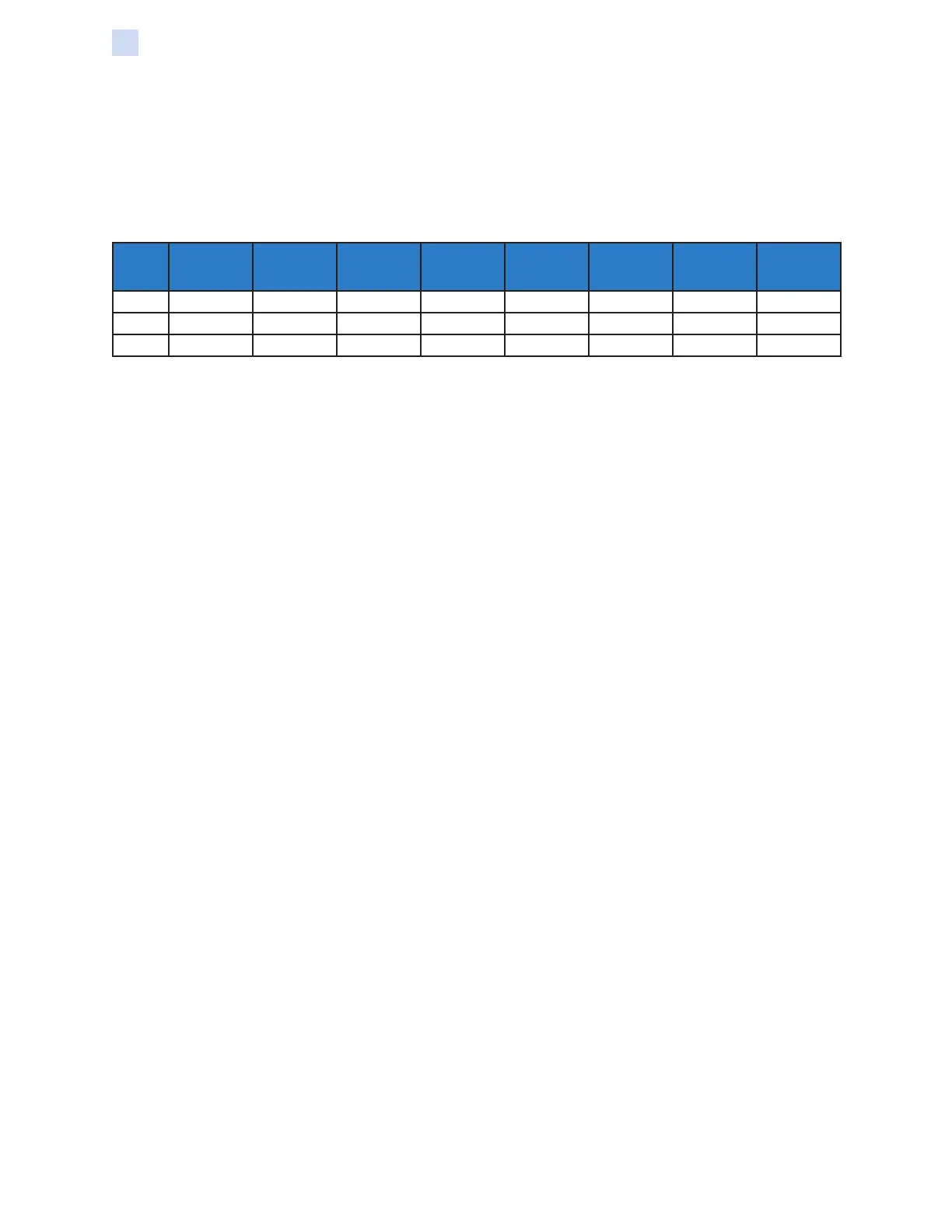

Track

Density (bits

per inch)

Bits per

character

Character

parity

Length

(characters)

LRC parity Start sentinel End sentinel

Start sentinel

offset inches

(mm)

1 210 7 Odd 79 Even % ? 0.293” (7.4)

2 75 5 Odd 37 Even ; ? 0.293” (7.4)

3 210 7 Odd 79 Even % ? 0.293” (7.4)

CUSTOM

If a custom format is desired, the ISO standard format may be used as a starting point. The standard

format can then be modied by assigning different values to any or all of the density, character, and

sentinel attributes. (If any of these attributes is missing, its corresponding value in the standard ISO

format will be substituted.)

BINARY

The binary option allows the user to specify directly the value for each bit on the mag stripe.

In this “direct binary” mode, it is the host’s responsibility to fully populate the magnetic stripe; i.e., the

hex data provided by the host must include the leading zeros, start sentinel, data, end sentinel, LRC,

and trailing zeros. Note that the magnetic stripe is encoded from the right-hand end as viewed from

the “stripe” side, with the stripe uppermost. The least signicant bit of the data is encoded rst.

A sufcient number of leading zeros should be prepended to offset the start sentinel by

approximately 0.3” (7.5 mm) from the right-hand end, as in the ISO format. Care should be taken to

ensure that the payload data does not exceed the capacity of the tracks at their specied recording

densities. (In the binary mode, out-of-range data is not recorded, and no error condition will result.)

A CR-80 size card has a nominal capacity of 252 bits per track at 75 BPI, and 708 bits at 210

BPI. These capacities equate approximately to 31 hex bytes (248 binary bits) and 88 hex bytes

respectively.

The application developer or user can use a preamble or Macro to indicate to the driver that the data

following the Preamble or Macro is to be mag encoded.

The user can have encoding and printing data on the same card, and the driver will filter out the

encoding data from the printing data. The user does not have to know job control syntax or ZMotif

commands to send mag encoding commands to the printer.

Supported Macro commands are:

Step 1. C01<Track1 Data>

C02<Track2 Data>

C03<Track3 Data>

Step 2. ${1<Track1 data>}$

${2<Track2 data>}$

${3<Track3 data>}$

Step 3. ~1=<Track1 data>

~2=<Track2 data>

~3=<Track3 data>

Using Partial-Width Laminate

Loading...

Loading...