03/2003

1-13

8850/ 510DP

Maintenance Procedures

Service Call Procedures

Maintenance Procedures

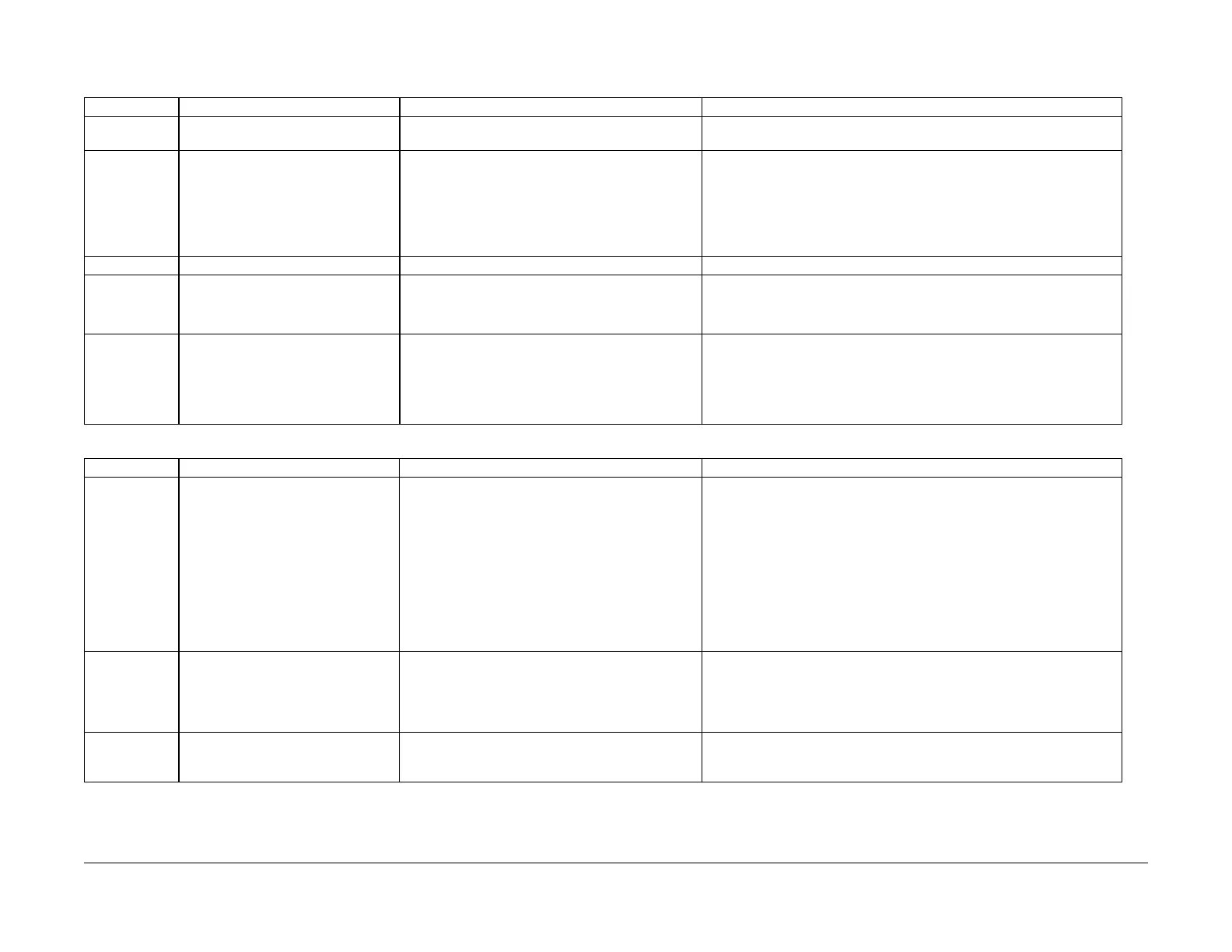

Table 1 Image Module

INTERVAL TASK REASON TASK ENABLER

Normal Call Check, clean, or repair spacing wheels

as required.

Contaminated, dirty or worn spacing wheels or Drum

ends cause print quality defects.

Clean or replace spacing wheels and the end surface of the Drum that the

wheels ride on.

Normal Call Check and clean, if required, the

charge Scorotron.

Contaminated grid, bent or contaminated pins. Worn

end blocks, are also causes for scorotron failure,

which results in print quality defects.

WARNING

The scorotron pin arrays are very sharp. Use care when handling the

assembly.

If contaminated, remove scorotron assembly and clean both sides of the

grid with a brush. Examine pins and clean with brush Only if contaminated.

Cleaning with a cloth can deposit lint that will cause print quality problems.

Normal Call Clean the image bar. Contamination causes print quality defects. Clean the image bar with a lint free cloth and lens cleaner.

15K ft.

4.5Km

Clean the Scorotron Screen. Contamination on the screen causes print quality

defects

Remove the Scorotron Screen and clean it with a brush.

NOTE: Do not use a cloth to clean the Scorotron Screen as it can leave lint

on the screen, causing print quality problems.

As Required Repair or replace the scorotron/ grid. Contamination causes print quality defects.

WARNING

The scorotron pin arrays are very sharp. Use care when handling the

assembly.

Replace the grid and/or pin array.

Perform ADJ 9.2 Electrostatic Series.

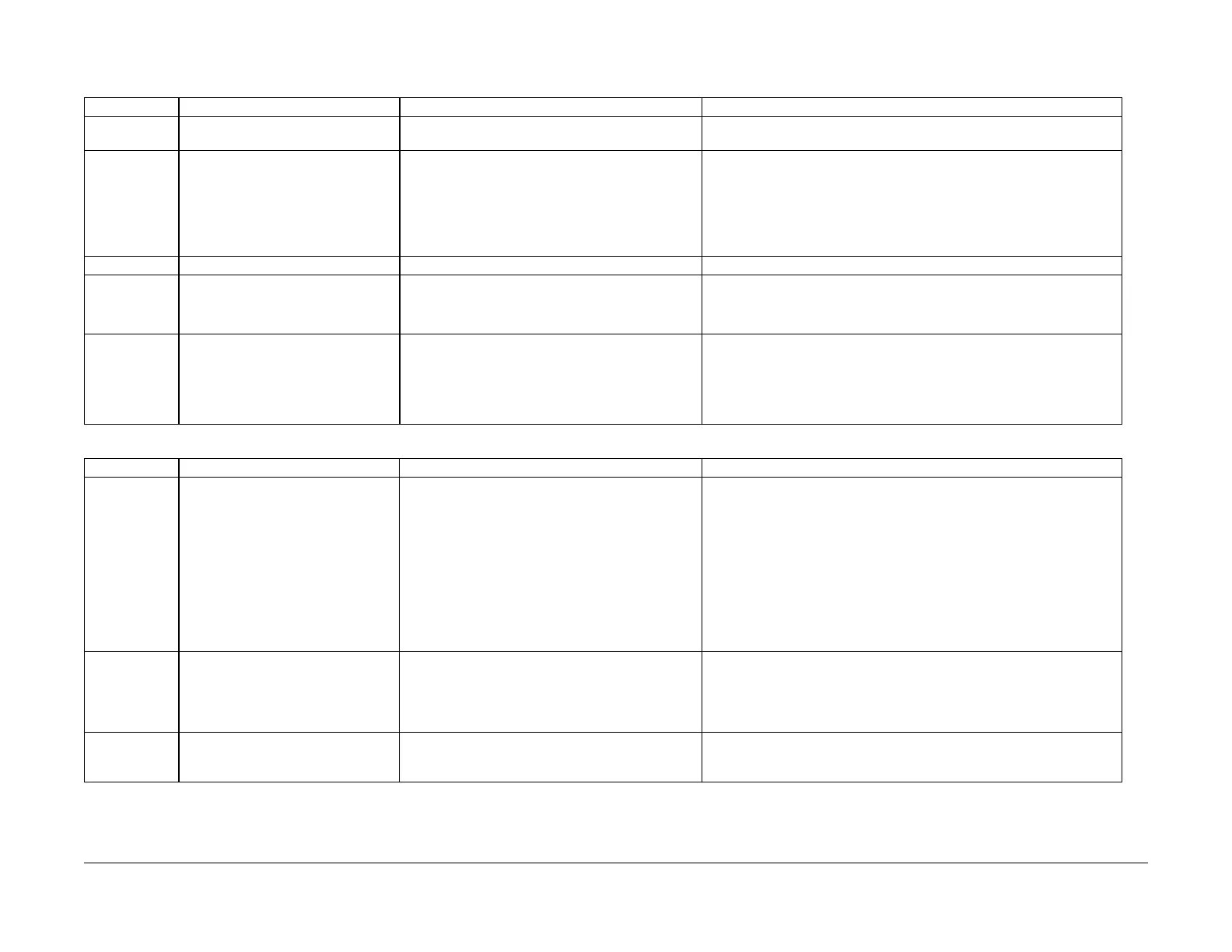

Table 2 Drum/ Cleaner Module

INTERVAL TASK REASON TASK ENABLER

Normal Call Clean the Drum/cleaner module.

Clean the Erase Bar.

Inspect the Drum for damage.

Inspect components for vellum con-

tamination.

Inspect all seals for damage.

Inspect the Cleaner Blade for damage.

Contamination can cause print quality problems. Con-

taminants can travel to the LED bar and scorotrons,

which results in print quality problems. Fused toner on

the bottom of the module can cause jams.

Contamination reduces the effectiveness of the lamp

to discharge the Drum.

Contaminants from vellum

- Cleaner failure

- Contaminants to prints.

Vellum contamination will contaminate and plug the

cleaner auger at the ends.

Clean the toner from the housing and cleaner blade with a vacuum cleaner.

NOTE: Ensure that the vacuum cleaner does not contact the edge of the

cleaner blade that touches the surface of the Drum.

Perform the Drum Cleaning Enhancement procedure in section 6. Use

cleaning solvent to remove any fused toner from the bottom of the module.

Replace the Drum if damaged.

Clean the Erase Bar with a brush or dry lint free cloth.

Replace any damaged xerographic module seals.

As Required Check/clean the Drum. Contamination/wear, scratches, or chips can generate

print quality problems.

Inspect Drum surface for deep scratches, chips or excessive wear. Replace

Drum if damaged.

Apply zinc stearate to the cleaning blade and Drum. *Note 2

Clean Drum surface with Xerox Film Remover if contaminated. Apply zinc

stearate when surface is dry.

As Required

*Note 3

Check/clean the cleaning blade.

Replace with the new Drum or as

required.

Residual image, streaks, Drum scuffing can occur if

the blade is worn or contaminated.

Vacuum clean the cleaning blade. *Note 1

Apply zinc stearate to the cleaning blade and Drum. *Note 2

Replace the blade if damaged.

Loading...

Loading...