03/2003

3-9

8850/ 510DP

Damaged Media, Media Handling Problems

Print Quality

Damaged Media Media Handling Problems

Introduction

Experience has shown that many media transportation problems have more than one cause

and must be handled using a systematic approach. Media transportation problems appear as

one of the following symptoms:

• Pre-fuser jams

• Bias Transfer Roll/transfer area jams

• Print quality defects

• Physical distortion of media

When these symptoms occur, perform the following checks of the media and Printer and per-

form the corrective actions.

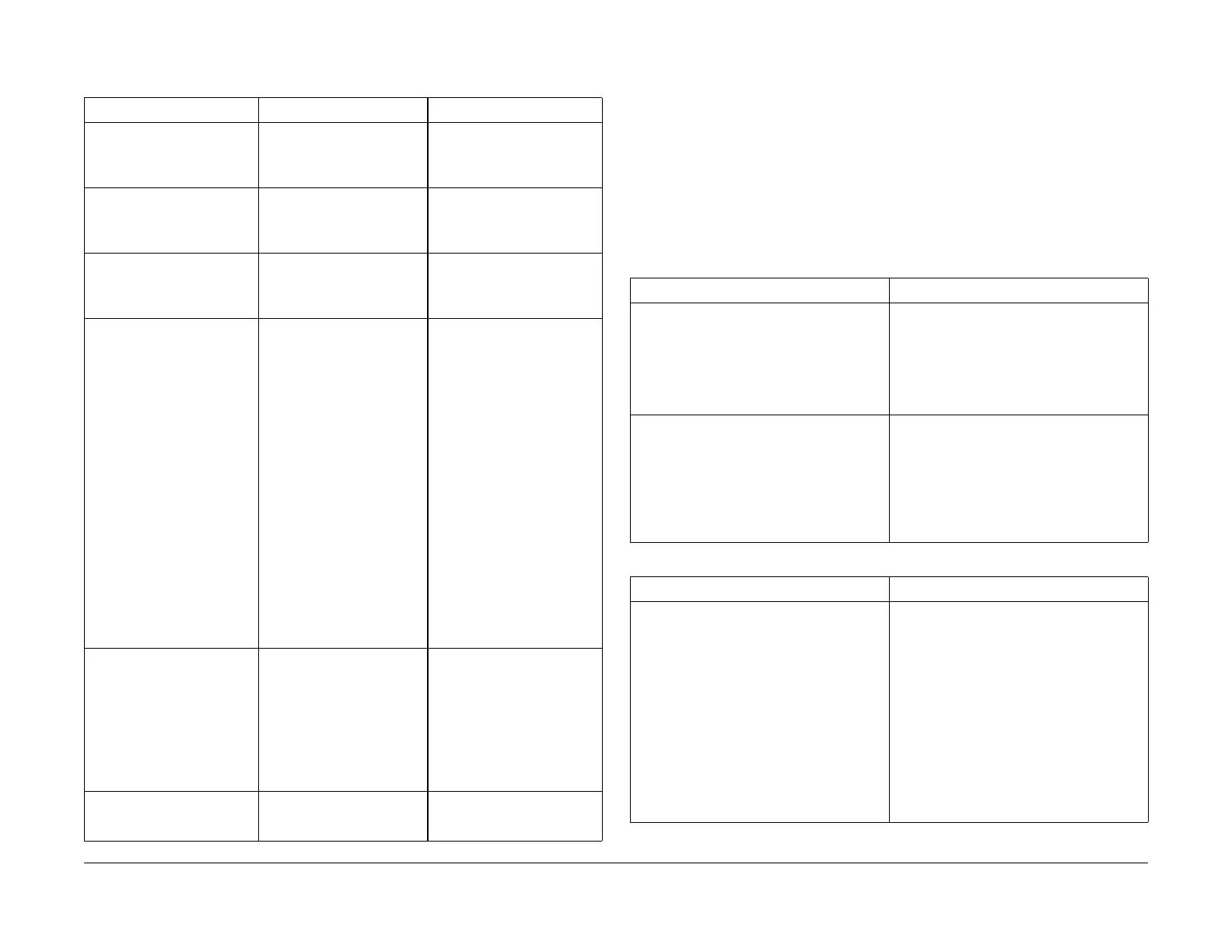

Table 1 Damaged Media

Defect probable cause corrective action

1. Crease Marks

A thin irregular line on the

media caused by stressing the

media.

1. This defect can be caused

by incorrect handling of the

media.

1. Ensure that the media is

stored correctly and is not

damaged when inserted in the

Printer.

2. Dog Ears

This is a corner of the lead

edge of the print that has been

bent back.

2. Curled media caused by a

failed or damaged Detack

Corotron.

2a. Try using a new roll of

media.

2b. Check for an obstruction

caused by a Detack Corotron.

3. Frayed Side Edge

This is damage to the sides of

the print.

3. Incorrect media side to

side registration

3. Ensure that the media is

loaded correctly.

Check the media path for an

obstruction.

4. Wrinkle

This is damage that is proba-

bly caused by the fuser sub-

system. This is a severe case

of creases that runs in the

direction of media travel.

4a. Damage or obstruction in

the media path.

4b. Damp media

4c. Pressure Roll is contami-

nated or damaged.

4d. Incorrect fuser pressure.

4e. Fuser Heat Roll is con-

taminated or damaged.

4f. Pressure Roll is contami-

nated or damaged.

4a. Clear the media path of

obstructions.

4b. Ensure that the Customer

is storing the media correctly.

Refer to BSD 10.3, BSD 7.2

and BSD 7.4 to check for cor-

rect operation of the Media

heaters (HR1, HR3).

4c. Refer to BSD 10.3 and

check that the Pressure Roll is

not contaminated or damaged.

4d. Check that the Pressure

Roll Springs (2) are not dam-

aged and are installed cor-

rectly.

4e. Clean/ replace the Fuser

Heat Roll (REP 10.2).

4f. Clean/ replace the Pres-

sure Roll REP 10.8.

4g. Check that Tag 4 Media

Corner Curl kit is installed.

5. Cockle

The media has a rough sur-

face like an orange peel.

This damage could be caused

by the fuser subsystem.

5a. Damage or obstruction in

the media path

5b. Fuser is too hot.

5c. Damp media.

5a. Clear the media path of

obstructions.

5b. Check Fuser Temperature

(ADJ 10.1)

5c. Ensure that the Customer

is storing the media correctly.

Refer to BSD 7.1 and BSD 7.3

to check for correct operation

of the Paper heaters.

6. Other Damage 6. If there are other defects on

the print, go to Media Handling

Problems on, following page.

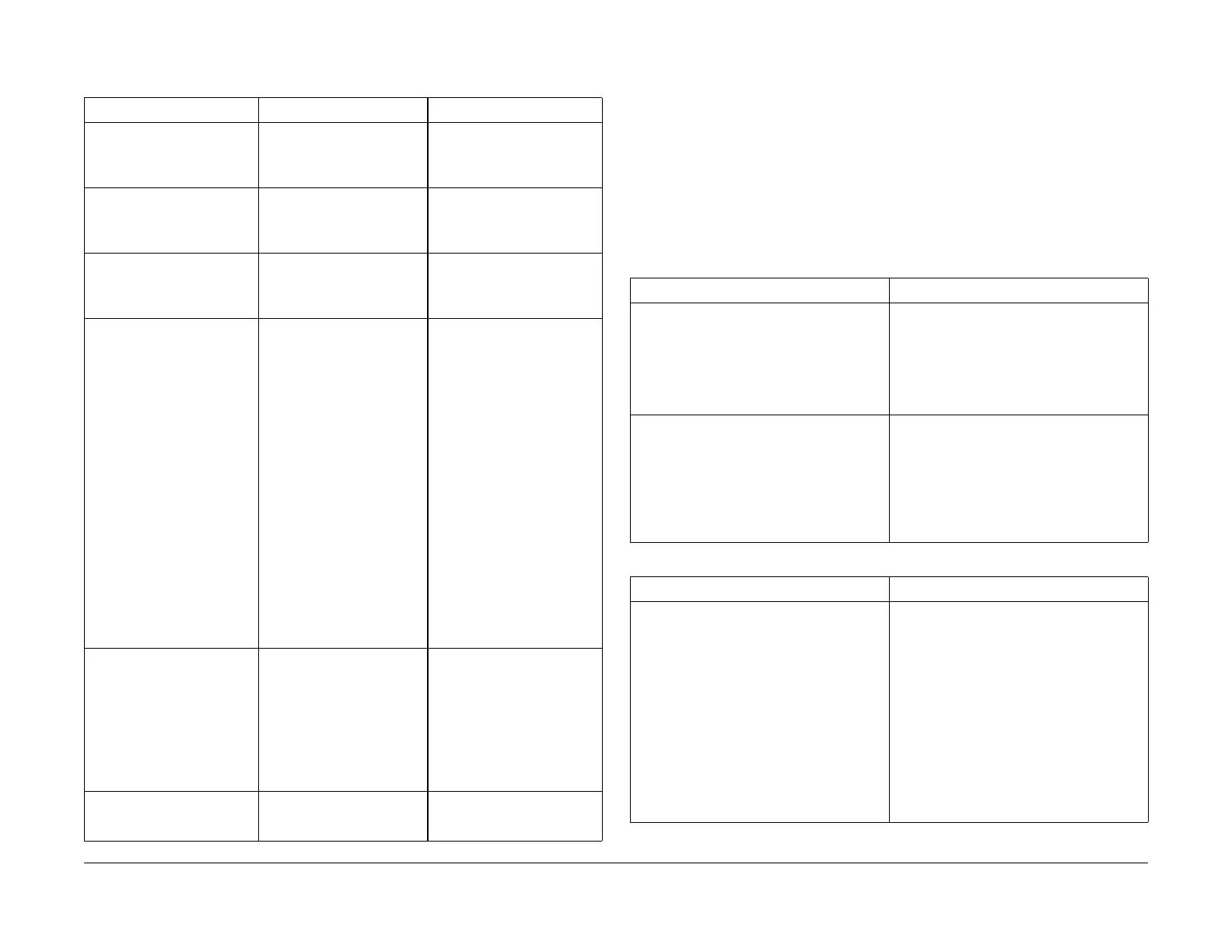

Table 1 Media Check

Media Check Corrective Action

1. Check the type of media:

a. Bond media less than 20 lb may perform

with less reliability than Xerox 20 lb.

b. Other brands of media may have different

design specifications than Xerox media and

may not give acceptable performance in the

Printer.

a. Use Xerox-qualified media.

b. After all media checks, test with fresh Xerox

media.

2. Check the storage of media:

a. Media that is exposed to the environment

may have damp areas.

b. Media may have curled ends because of

incorrect storage.

a. Suggest keeping the media in the package

in which the Xerox media is shipped until the

media is to be used.

b. Suggest that the media should be stored

correctly.

c. Recommend keeping the Printer switched

on overnight to help eliminate moisture

buildup.

Table 2 Printer Check

Printer Check Corrective Action

1. Contaminated or damaged Detack

Corotron resulting in an open circuit or arcing.

2. An incorrect electrostatic value can cause

jams or deletions.

3. Warped Media Transport Module frame.

4. Broken or damaged Media Shield

5. Check the stainless steel media Clips (PL

8.3) are seated fully (no space between the

Clips and the wall of the Detack Corotron

channel).

6. Check that Tag 4, Media Corner Curl Kit is

installed.

1. Clean or replace if necessary (REP 9.9).

2. Check the following:

a. Clean or replace the Detack Corotron as

required (PL 8.3).

3. With a straight edge, check flatness of the

extrusion wall between the BTR and Detack.

Replace Detack and BTR Exreusion (PL 8.1)

4. Replace the Media Shield (PL 8.3)

5. Replace the Clips as required (PL 8.3) .

6. Install the Media Corner Curl Kit. (8850

Change Tag Information)

Loading...

Loading...