03/2003

3-16

8850/ 510DP

PQ 13, PQ 14

Print Quality

PQ 13 Light Image PQ 14 Misregistration

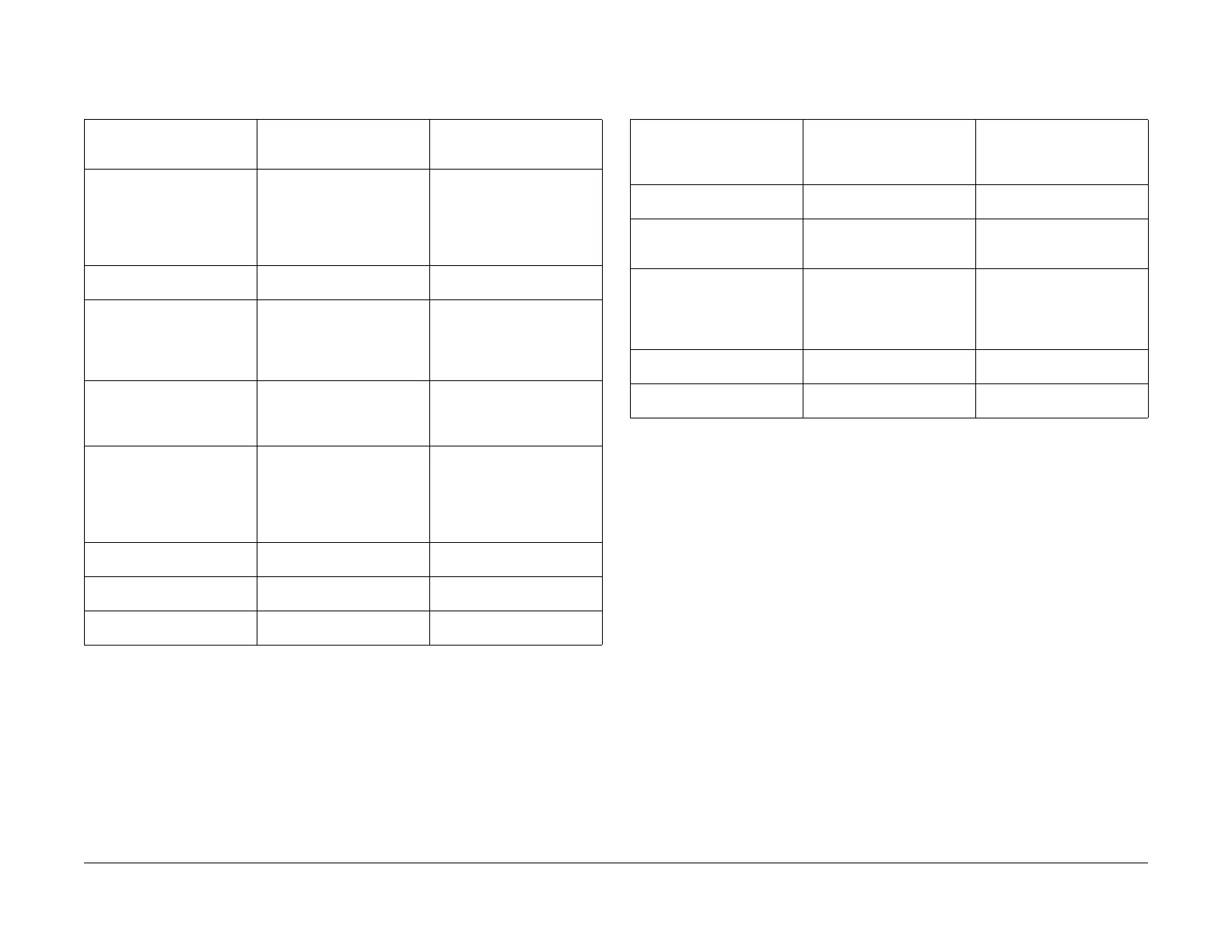

Table 1 Light Image Symptom / Check

Symptom/ check

Image area of a print has low

density.

Probable Cause Corrective Action

1. Damp media 1A. Refer to BSD 7.1 and

BSD 7.3 to check for correct

operation of the Paper heat-

ers.

1B. Ensure that the Customer

is storing the media correctly.

2. Incorrect Image Module

LED duty cycle

2. Perform Electrostatic

Series (ADJ 9.2).

3. Incorrect Corotron opera-

tion

3A. Perform Electrostatic

Series (ADJ 9.2)

3B. Perform GP 1, Xero-

graphic HVPS Checkout Pro-

cedure.

4. Incorrect Image Density

adjustment

4A. Perform Electrostatic

Series (ADJ 9.2).

4B. Perform Image Density

(ADJ 9.3).

5. Contaminated BTR, dam-

aged drive gears or poor elec-

trical connection

5. Check/ clean/ repair BTR

Slip Ring connection.

Check/ replace drive gears

(PL).

Clean/ replace BTR (REP

9.22),

6. Defective Drum ground. 6. Ensure that the Drum is

correctly grounded.

7. Defective Drum. 7. Replace the Drum (REP

9.3).

8. Developer Housing 8. Ensure the housing is

latched securely.

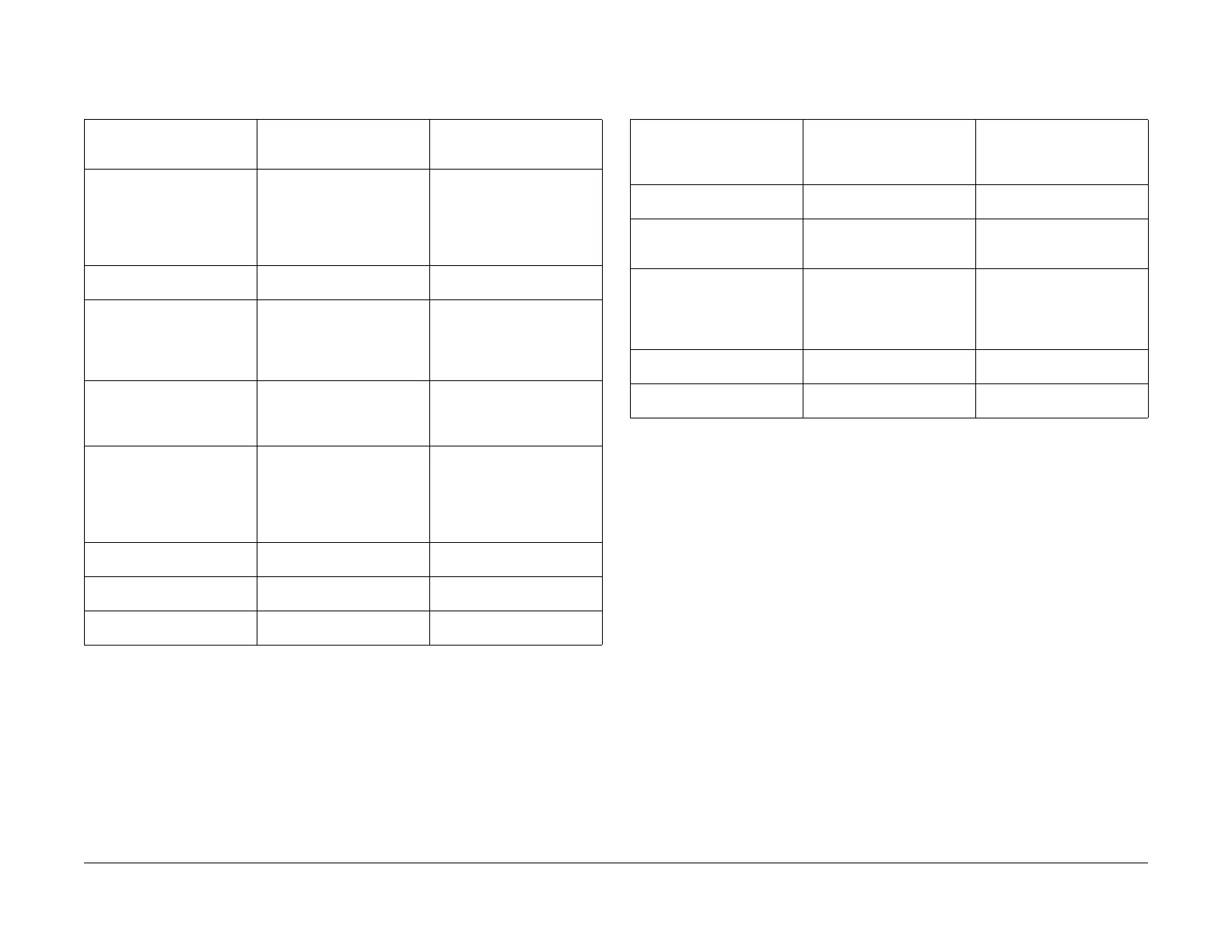

Table 1 Misregistration Symptom / Check

Symptom/ check

The registration of the image

on the prints is incorrect from

top to bottom or side to side.

Probable Cause Corrective Action

1. Incorrect registration

adjustment

1. Adjust Lead Edge Registra-

tion (ADJ 8.2).

2. Damaged or worn compo-

nents in the media feeding

area

2. Check the components for

damage or wear.

3. Defective Media Registra-

tion Sensor

3. Refer to BSD 8.1 and

check the operation of the

Media Registration Sensor.

Replace the sensor if required

(REP 8.8).

4. Incorrect Registration

Pinch Roll nip

4. Clean or replace the Regis-

tration Pinch Roll (PL 8.2).

5. Incorrectly loaded media 5. Instruct the operator on

loading the media correctly.

Loading...

Loading...