03/2003

3-19

8850/ 510DP

PQ 18, PQ 19

Print Quality

PQ 18 Spots PQ 19 Uneven Density

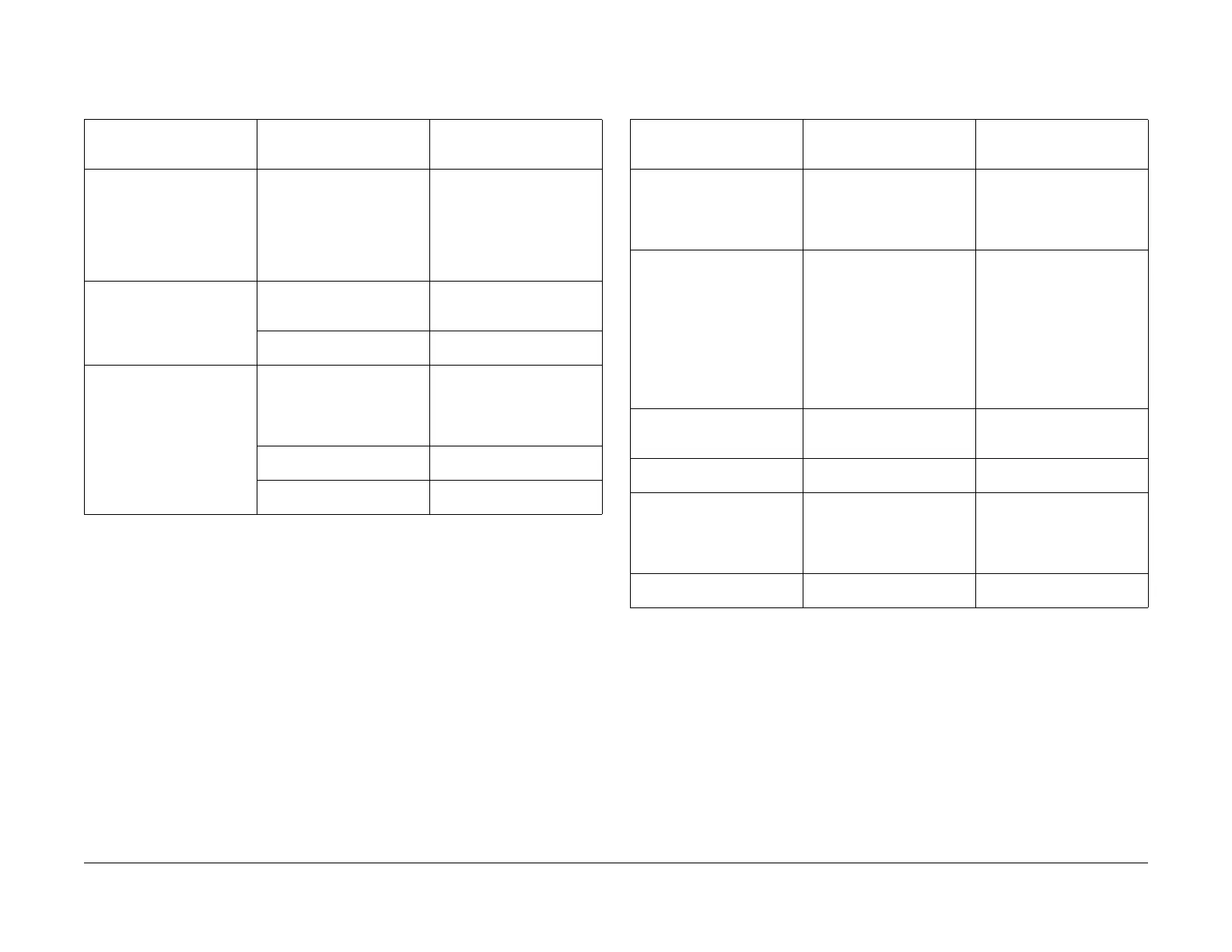

Table 1 Spots Symptom / Check

Symptom/ check

Circular black spots on the

print.

Probable Cause Corrective Action

Perform Panic Stop/Image on

Drum procedure (GP 2), and

examine the Drum for the

defect.

1. Defective, damaged or con-

taminated Drum

1A. Wash the Drum (GP 3

Drum Maintenance)

1B. If the Drum is damaged,

determine and fix the cause of

the damage to the Drum.

1C. Replace the Drum (REP

9.3).

Repetitive spots 2. Contaminated Fuser Heat

and/ or Pressure Roll

2. Clean or replace the Heat/

Pressure roll (REP 10.2, REP

10.8).

3. Contaminated fuser ther-

mistor

3. Clean the thermistor (PL

10.4).

Random spots 4. Contaminated Web Oiler 4A. Check/ replace Web Oiler

(REP 10.5).

4B. Check/ adjust oil dis-

pense rate [10-32] (Special

Tests).

5. Defective Photoreceptor

Seal

5. Check / replace (PL 9.3).

6. Charge scorotron 6. Clean or replace the

scorotron (REP 9.8).

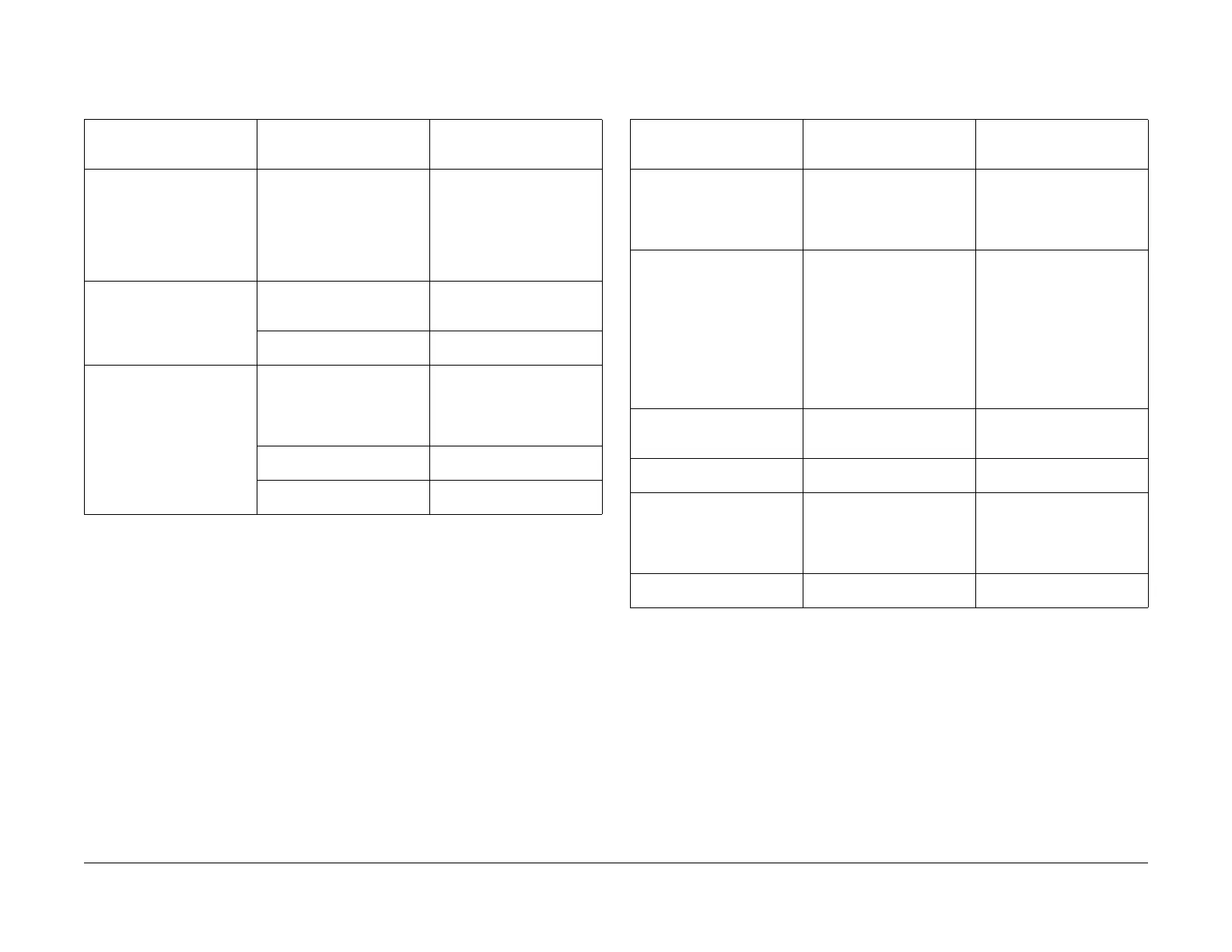

Table 1 Uneven Density Symptom / Check

Symptom/ check

Density and line thickness

vary across the print.

Probable Cause Corrective Action

1. Incorrect Corotron opera-

tion

1A. Perform Electrostatic

Series (ADJ 9.2)

1B. Perform GP 1, Xero-

graphic HVPS Checkout Pro-

cedure.

2. Contaminated LED Image

Bar

2A. Check / clean the Image

Bar. .

2B. Check / clean the Pres-

sure Equalizer Tubes (PL 9.9)

2C. Check that the Toner Dust

Trap, Tubes are not plugged.

Replace as required (PL

9.10).

2D. Check/Replace the Toner

Filter (PL 9.10).

3. Machine level 3. Check the level of the

machine. (See Installation

Procedure in Section 6.

4. Contaminated/ damaged

BTR

4. Clean/ replace BTR or

Spacing Rollers (PL 8.3)

5. Developer mag brush not

contacting the Drum evenly.

5A. Clean Drum ends and the

Spacer Rolls on the Devel-

oper Housing (PL 9.10).

5B. Ensure that the housing

is latched securely.

6. Defective Drum 6. Clean or replace the Drum

(REP 9.3).

Loading...

Loading...