03/2003

3-15

8850/ 510DP

PQ 11, PQ 12

Print Quality

PQ 11 Deletions (spots) PQ 12 Finger Marks

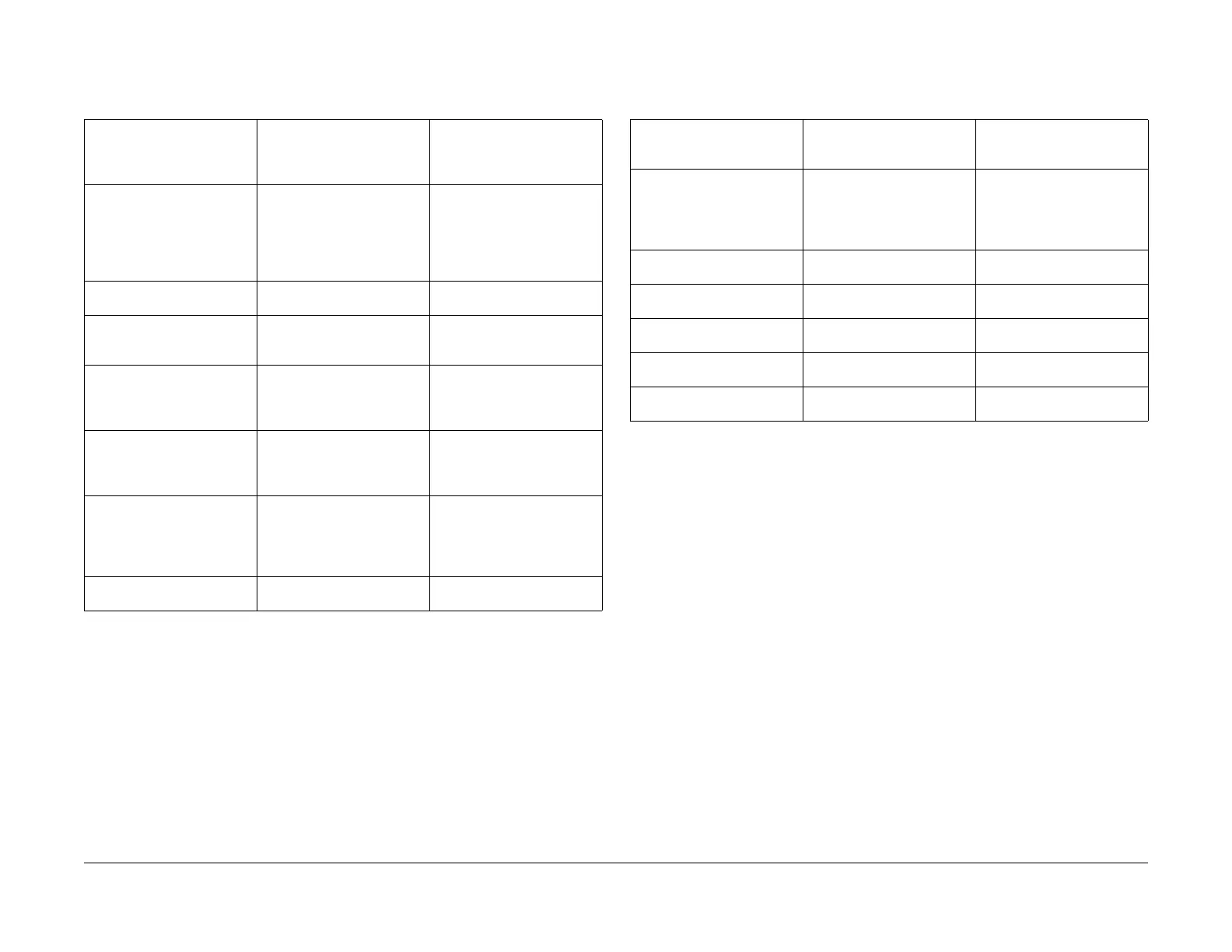

Table 1 Deletions (spots) Symptom / Check

Symptom/ check

Localized areas of deletion in

the solid or halftone areas in

the print feed direction.

Probable Cause Corrective Action

1. Damp media 1A. Refer to BSD 7.1 and

BSD 7.3 to check for correct

operation of the Paper heat-

ers.

1B. Ensure that the Customer

is storing the media correctly.

2. BTR contaminated or dam-

aged.

2. Clean/ replace BTR or

Spacing Rolls, (REP 9.22).

3. Detack Corotron 3. Perform GP 1, Xero-

graphic HVPS Checkout Pro-

cedure.

4. Developer Housing 4A. Ensure that the housing

is latched securely.

4B. Check the mag roll for

damage or binding.

5. Insufficient toner resulting

in developer bead carryover.

5A. Perform Electrostatic

Series (ADJ 9.2).

5B. Perform Image Density

(ADJ 9.3).

6. The surface of the Fuser

Heat Roll and/or Pressure

Roll is damaged. Could also

be caused by Incorrect Oiler

operation.

6. Determine and correct the

cause of the damage to the

Rolls. Replace the Roll(s)

(REP 10.2, 10.8)

7. Defective Drum 7. Replace the Drum (REP

9.3).

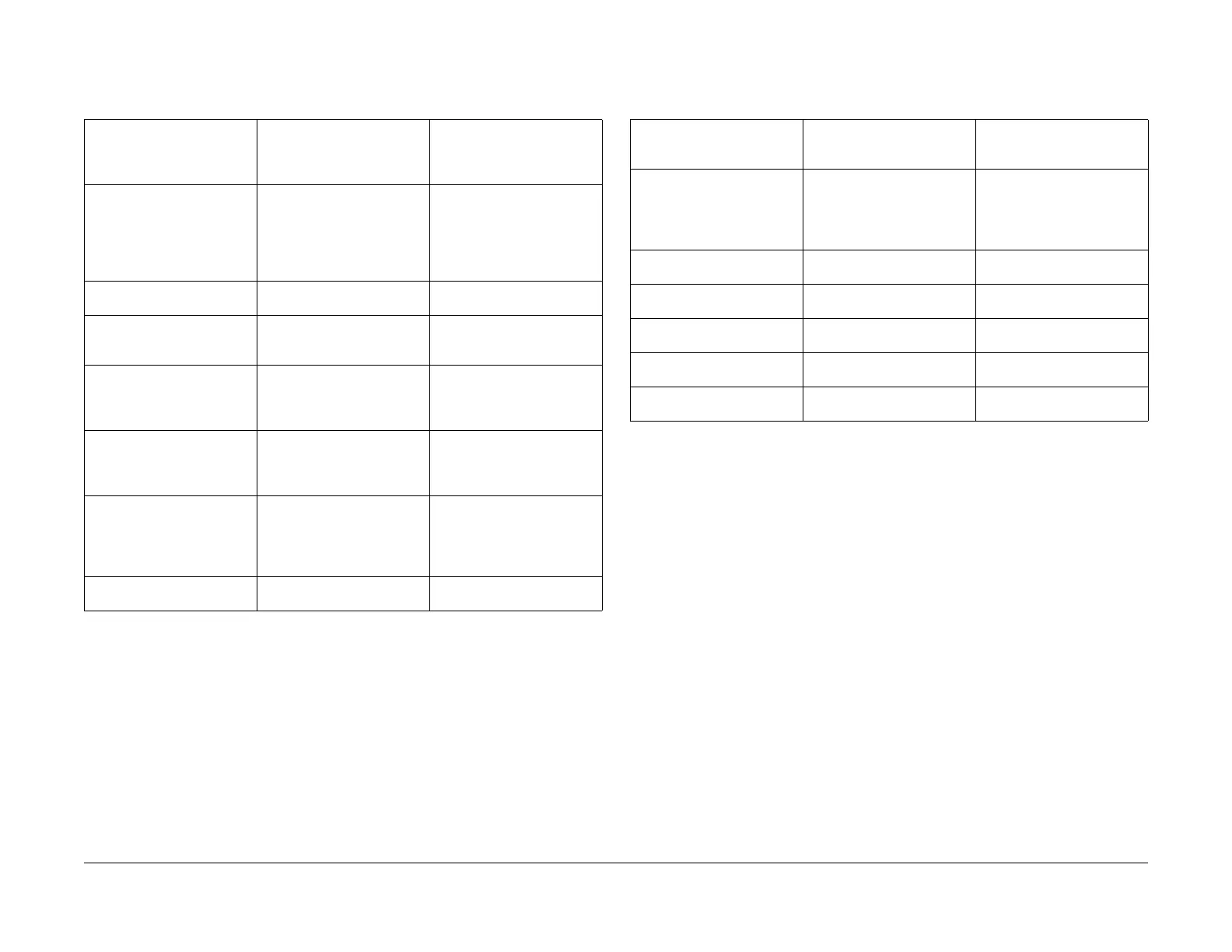

Table 1 Finger Marks Symptom / Check

Symptom/ check

Toner marks on the lead edge

or trail edge of the print.

Probable Cause Corrective Action

1. Defective or dirty Detack

Corotron

1A. Clean or replace the

Corotron (PL 9.4).

1B. Perform GP 1, Xero-

graphic HVPS Checkout Pro-

cedure.

2. Cleaner Seal 2. Check / clean as required.

(PL 9.5)

3. Web Oiler 3. Check/ Replace the Web

Oiler (REP 10.5).

4. Turnaround Baffle 4. Ensure that the baffle is

free of contamination (PL 8.2).

5. Fuser Heat Roll 5. Check / replace (REP

10.2)

6. Incorrect speed of paper

feed.

6. Check for incorrect soft-

ware revision level.

Loading...

Loading...