Rockwell Automation Publication 2198-UM002G-EN-P - February 2019 169

Connect the Kinetix 5700 Drive System Chapter 5

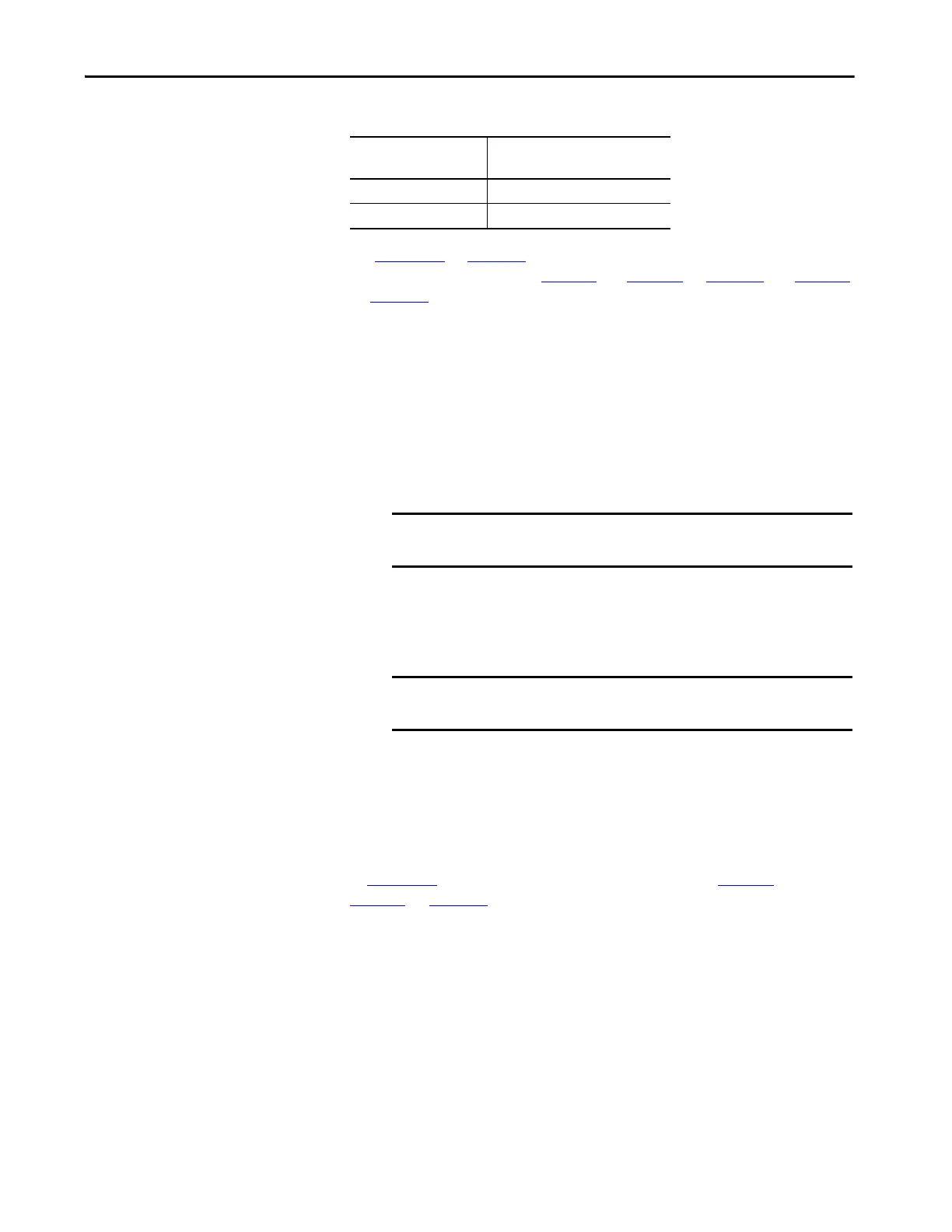

Table 90 - Brake Conductor Trimmed Length

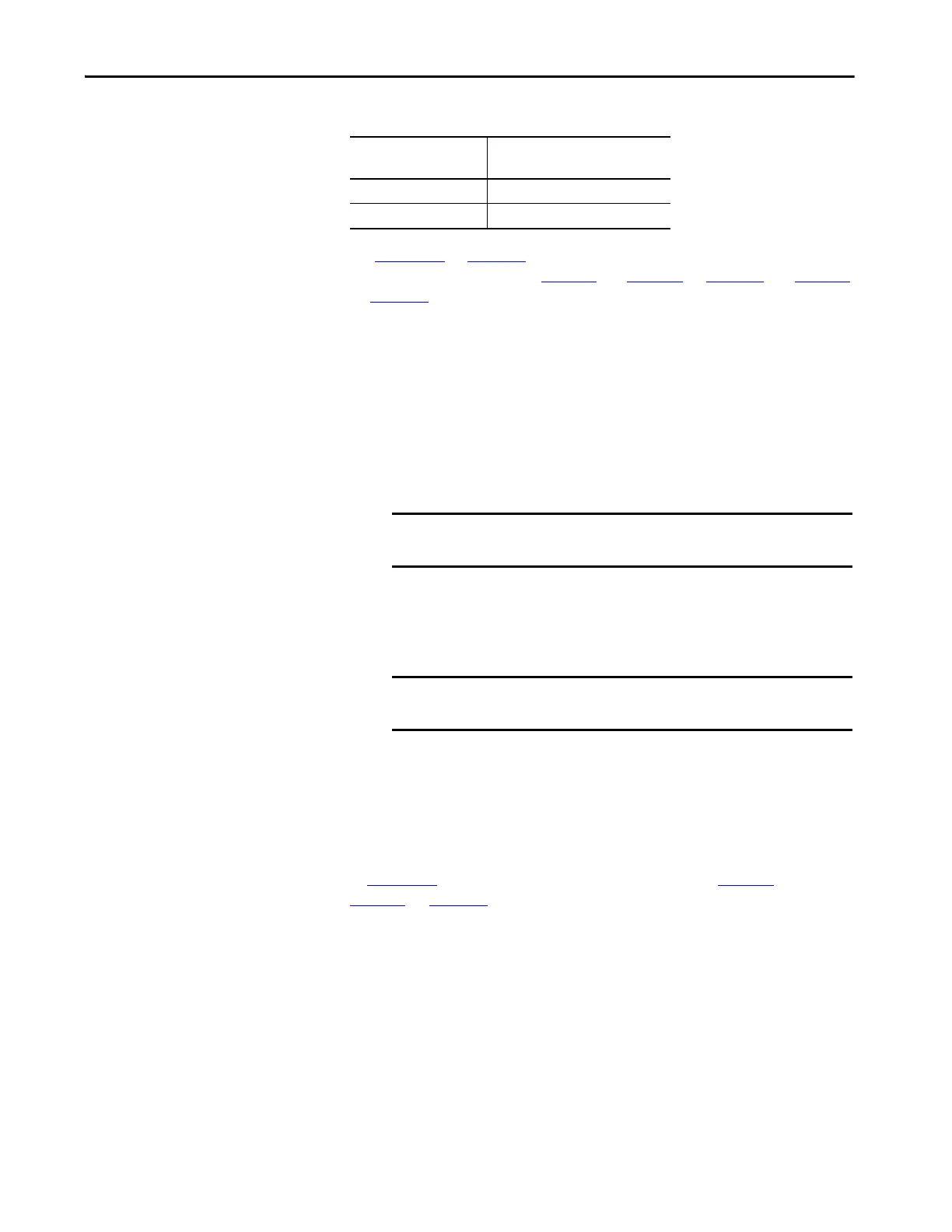

See Figure 112 on page 170 for a typical series-A installation example. For strip

lengths and torque values, see Ta b le 7 6

and Tabl e 77 on page 153 and Ta b le 78

on page 155

.

Single-axis Inverter Shield Clamp Installation

Follow these steps to apply the 2198-S086-ERSx, 2198-S130-ERSx, and

2198-S160-ERSx single-axis inverter motor-cable shield clamp when using

2090-CPBM7DF motor power cables.

1. Remove the larger (lower position) clamp or small (upper position)

clamp, depending on the power conductor size used in your application.

2. Loosen the clamp screw.

3. Position the exposed portion of the cable braid directly in line with the

clamp.

4. Tighten the clamp screw.

Make sure the cable clamp tightens around the overall cable shield and

provides a good bond between the cable shield and the drive chassis.

Torque value 5.6 N•m (50 lb•in), max.

In Figure 112

, 10 AWG (series A) cables are prepared per Tabl e 89 and

Tabl e 90

on page 169, and series B cables do not require preparation.

Power Conductor Size

AWG

Brake Conductor Length

mm (in.)

6, 8, 10 315 (12.4)

2 and 4 375 (14.7)

IMPORTANT Make sure to use the proper size clamp depending on cable

diameter.

IMPORTANT Make sure the clamp is aligned with the shield braid and not

heat shrink.

Loading...

Loading...