Theory of Operation 2-23

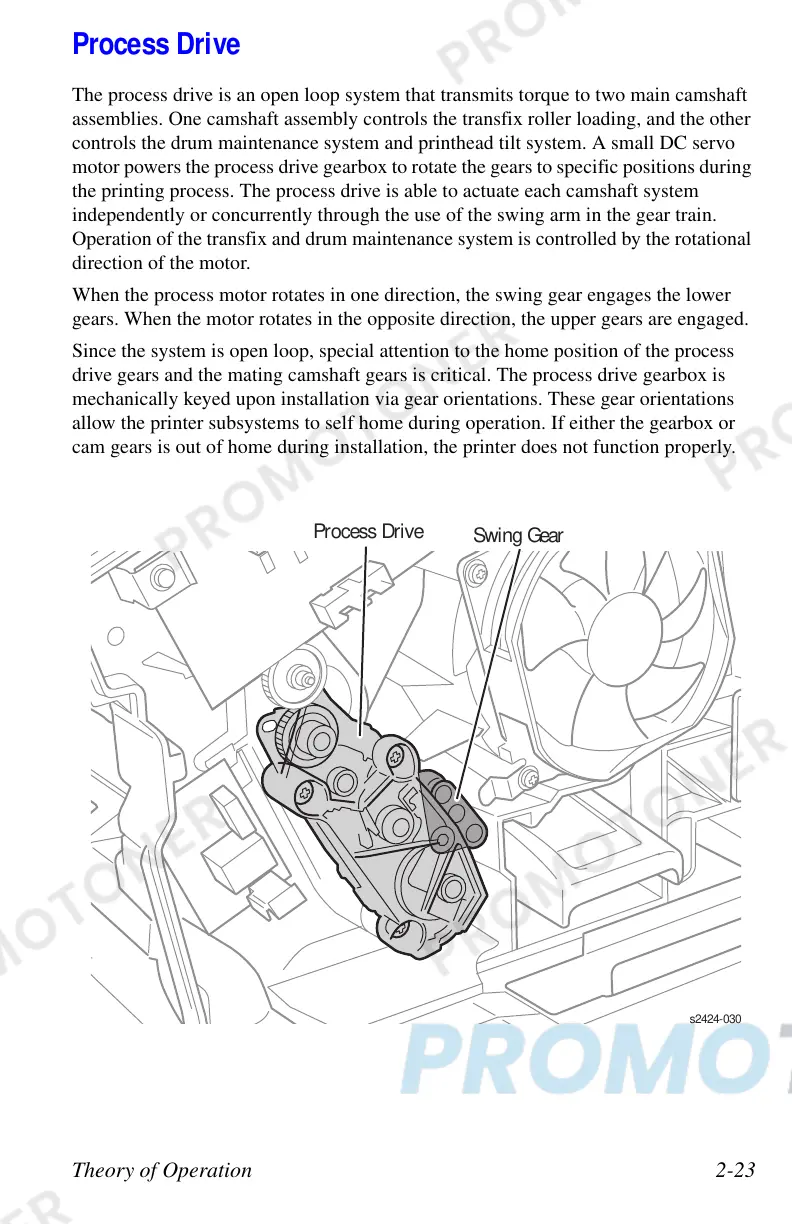

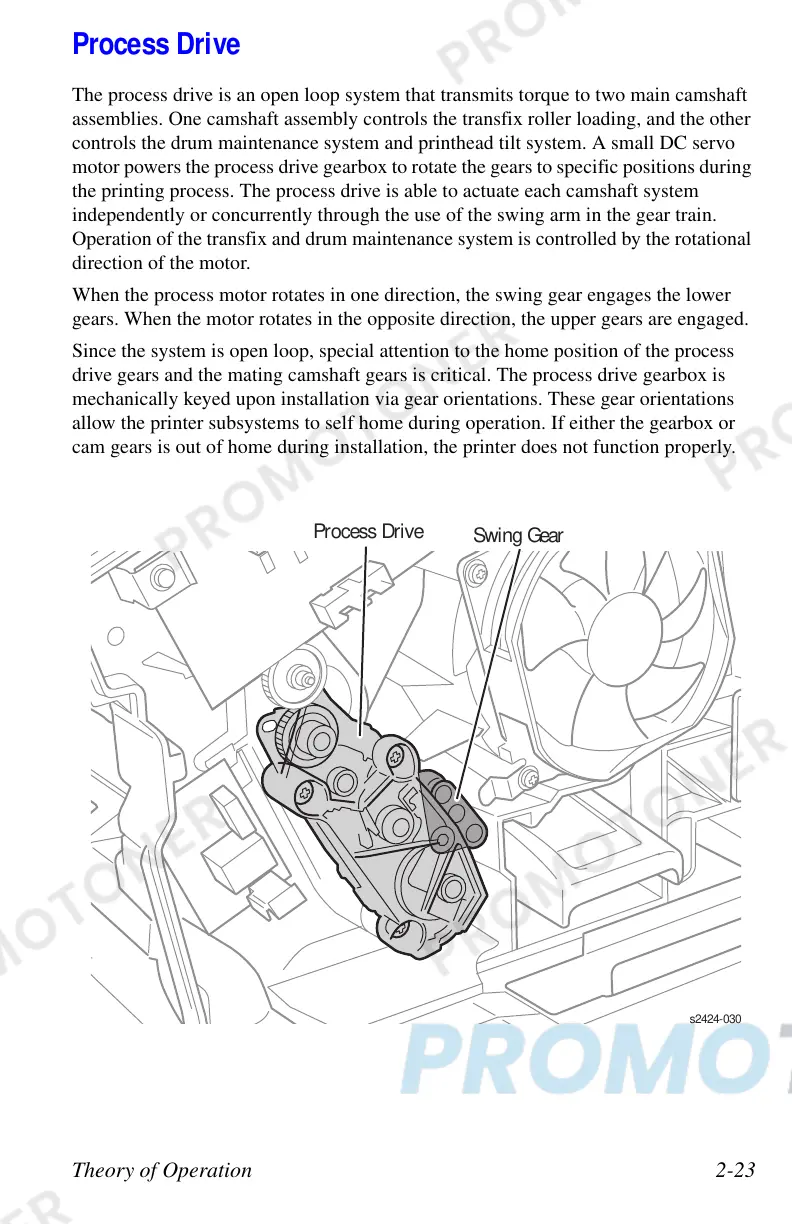

Process Drive

The process drive is an open loop system that transmits torque to two main camshaft

assemblies. One camshaft assembly controls the transfix roller loading, and the other

controls the drum maintenance system and printhead tilt system. A small DC servo

motor powers the process drive gearbox to rotate the gears to specific positions during

the printing process. The process drive is able to actuate each camshaft system

independently or concurrently through the use of the swing arm in the gear train.

Operation of the transfix and drum maintenance system is controlled by the rotational

direction of the motor.

When the process motor rotates in one direction, the swing gear engages the lower

gears. When the motor rotates in the opposite direction, the upper gears are engaged.

Since the system is open loop, special attention to the home position of the process

drive gears and the mating camshaft gears is critical. The process drive gearbox is

mechanically keyed upon installation via gear orientations. These gear orientations

allow the printer subsystems to self home during operation. If either the gearbox or

cam gears is out of home during installation, the printer does not function properly.

s2424-0

Swing Gear

Loading...

Loading...