February 2012 18 – 243

18 Power supply

18.1 Introduction

A machine tool uses different voltages ranging from few volts up to almost 1000 volts.

Some examples:

5 V voltage for powering the electronics

24 V voltage for powering the PLC

12 V voltage for powering the handwheel

650 V dc-link voltage for powering the drives

The voltages are supplied from different voltage sources.

Some examples:

400 V primary voltage

24 V PLC power supply unit

24 V NC power supply unit

Low-voltage power supply unit in the inverter or the UEC

In this chapter, the voltage sources are described as well as the systems and devices that operate

with these voltages.

18.2 Supply voltages in the HSCI system

Two 24 V supply

voltages

Two separate 24 V power supplies must be used to supply the +24 V power to the individual control

components in the HSCI system:

+24 V NC

+24 V PLC

Insulation of the

24 V supply

voltages

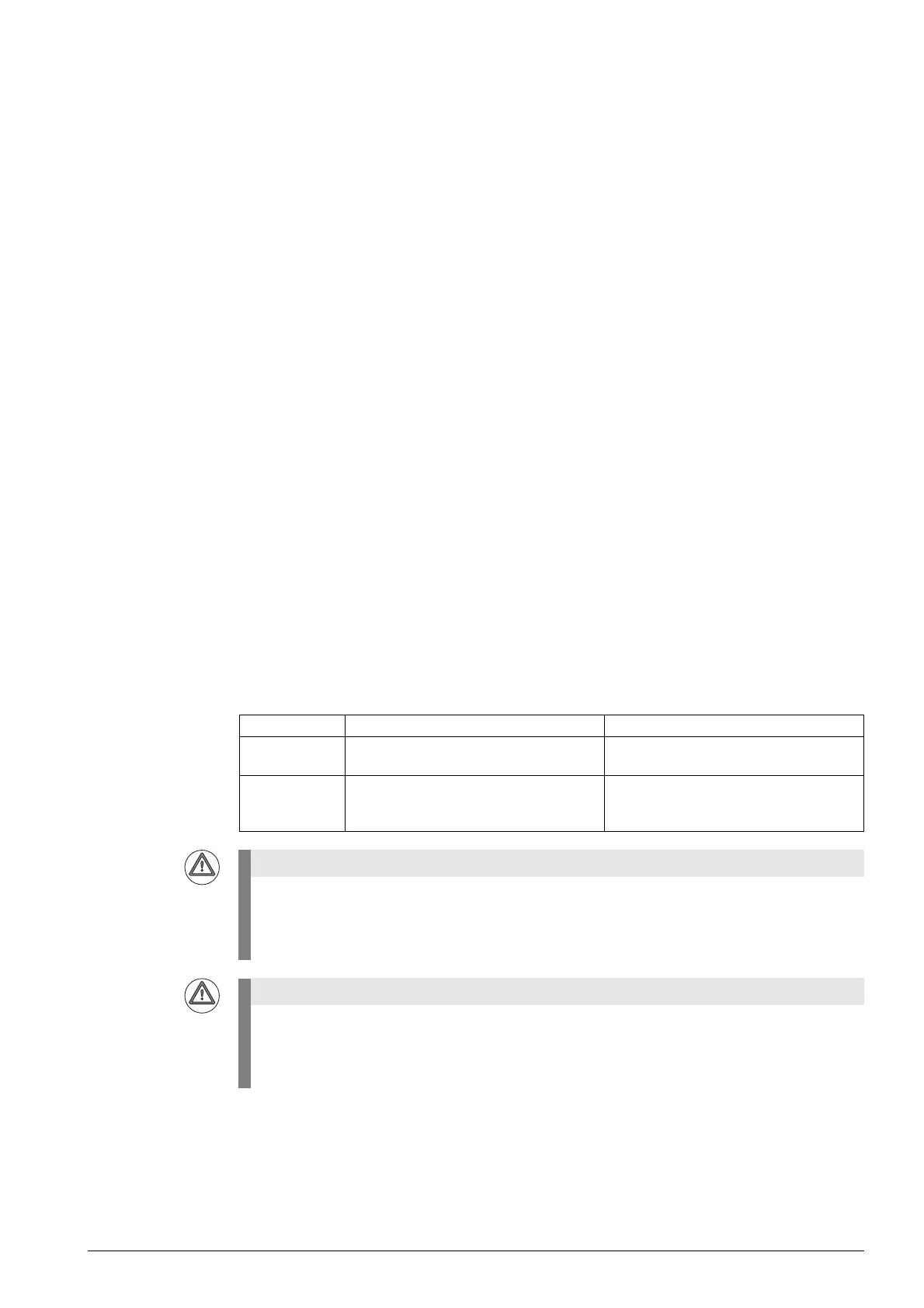

Designation 24 V-NC 24 V-PLC

Insulation Double basic insulation according to

EN 50 178 (PELV).

Simple basic insulation

according to EN 61800-5-1 (ELV)

Reason Electrical safety, e.g. accessibility of

connecting elements supplied with

+24 V NC voltage.

The two supply voltages must not be connected to each other.

The double basic insulation of the NC power supply would be removed through "mixed operation,"

i.e. +24 V NC voltage with double basic insulation connected to PLC components with simple

basic insulation. This is not permitted in an HSCI system.

VDE 0160/EN 50178 is to be observed for the +24 V NC voltage lines and cable routing.

Lines or cables for safely separated electric circuits thus must have double or reinforced insulation

between the wire and the surface if they are routed without spatial separation from other cables

and lines.

Loading...

Loading...