February 2012 6 – 65

6.7 Observing essential values with the integrated oscilloscope

The control receives three actual values:

Current

Spindle speed

Position

The actual current is evaluated by means of current sensors in the power output stage.

The actual speed is captured via the motor encoder.

With direct measurement the actual position is provided by, e.g., the linear scale.

From this information most of the signals in the integrated oscilloscope are formed.

The torque-determining current I noml is an important characteristic for the mechanics of the axis

concerned (stiffness, blunt tool, lubrication, utilization, etc.)

Like the current, also the servo lag s diff is an important characteristic for the mechanics of an axis.

At the moment of reversal the following error also allows for conclusions about insufficient feed-

forward adjustment, backlash, characteristics of belt, gear, coupling, etc.

For analog axes s diff also provides information on the speed adjustment.

(See ”Specific for pre-triggering” on page 10 – 104).

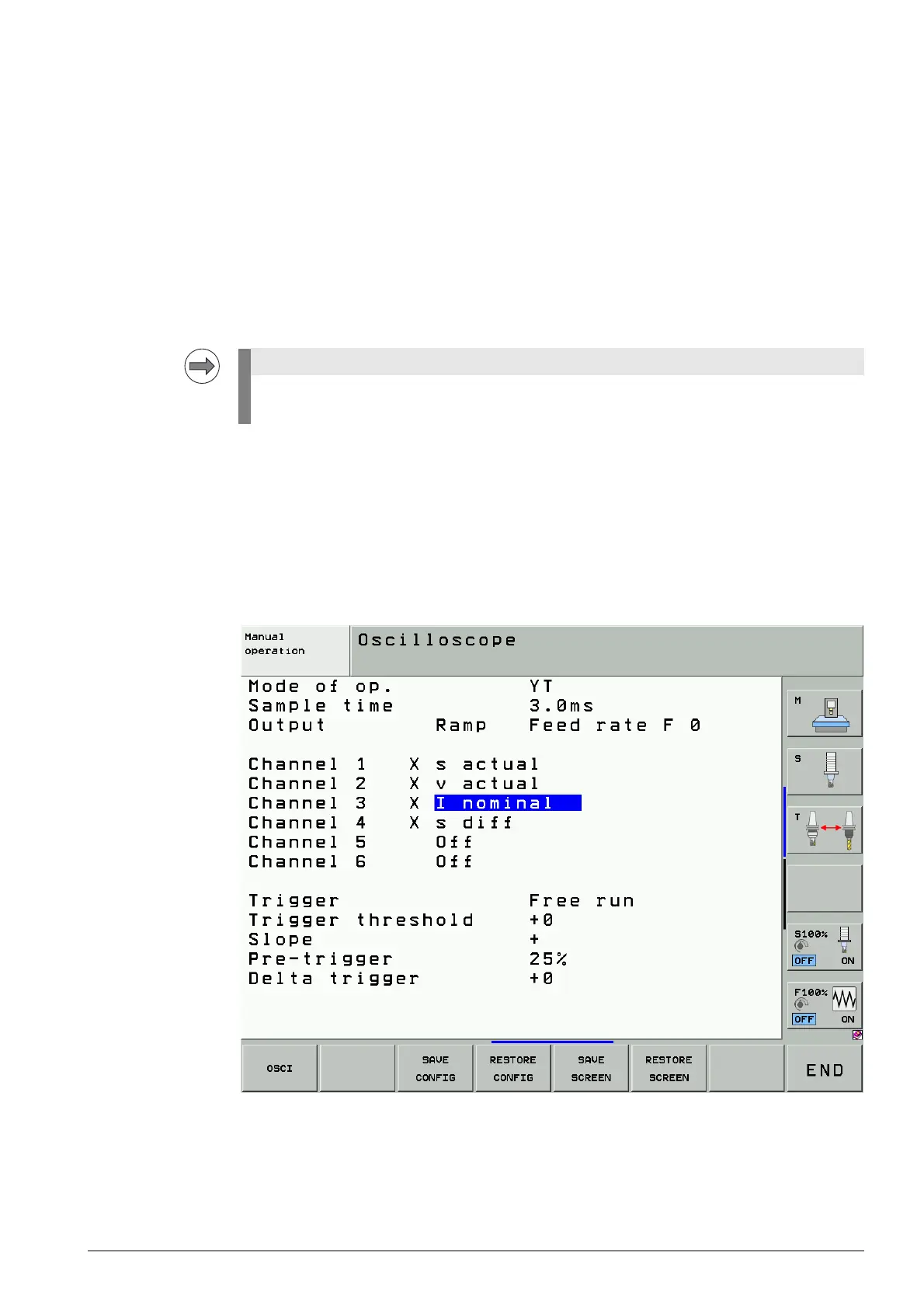

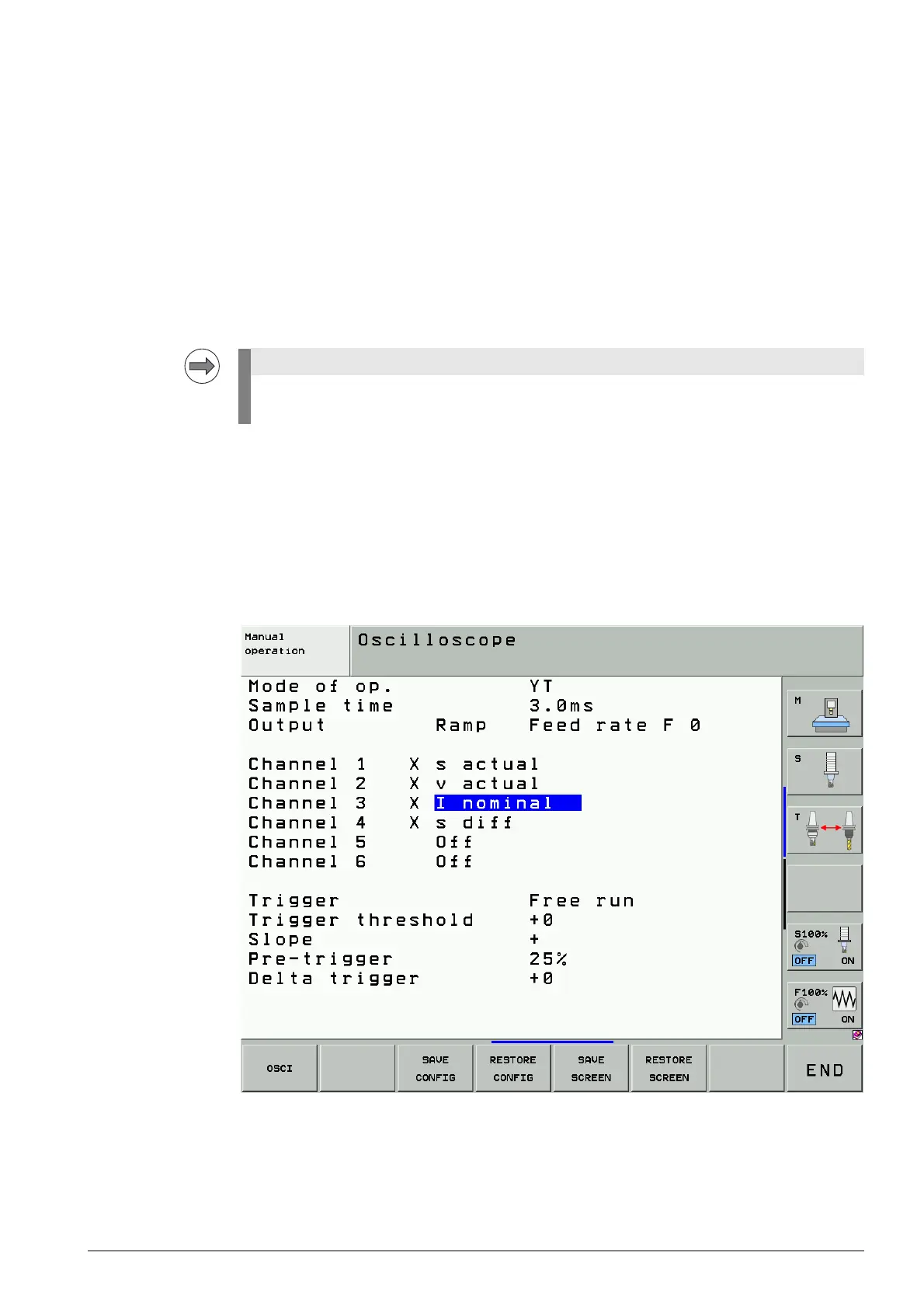

Example for a recording of essential values

(Activation and operation --> See ”Integrated oscilloscope” on page 10 – 95):

8 Make the following settings:

8 Move the machine axis in automatic or manual mode.

8 Start the oscilloscope recording.

8 Stop recording and adjust the signals.

Other signals, such as I2-t (mot.), I2-t (p.m.) and Utilization are calculated from the

current.

Loading...

Loading...