February 2012 19 – 279

EnDat encoders EnDat encoders may be connected to all position encoder inputs of a CC 61xx or a UEC 11x.

Memory areas in

the EnDat encoder

EnDat encoders offer the possibility of storing machine or system-dependent data in the memory

area reserved for the machine tool builder.

19.1.2 Machine parameters

Monitoring of the

position encoders

The monitoring functions for the position encoders of the axes are activated in MP20.x.

The monitoring functions for the position encoders of the spindles are activated in MP21.x.

The following criteria are checked:

Connection of the

position encoders

MP100 is read from the right to the left and contains the information which axis is the first, the second,

the third, etc.

In MP108 you can see the assignment of the axes to the controller basic boards.

In MP109 you can see the assignment of the spindles to the controller basic boards.

In MP110 you can see the assignment of the axes to the position encoder inputs (connector X201 and

following).

In MP111 you can see the assignment of the spindles to the position encoder inputs (connector X201

and following).

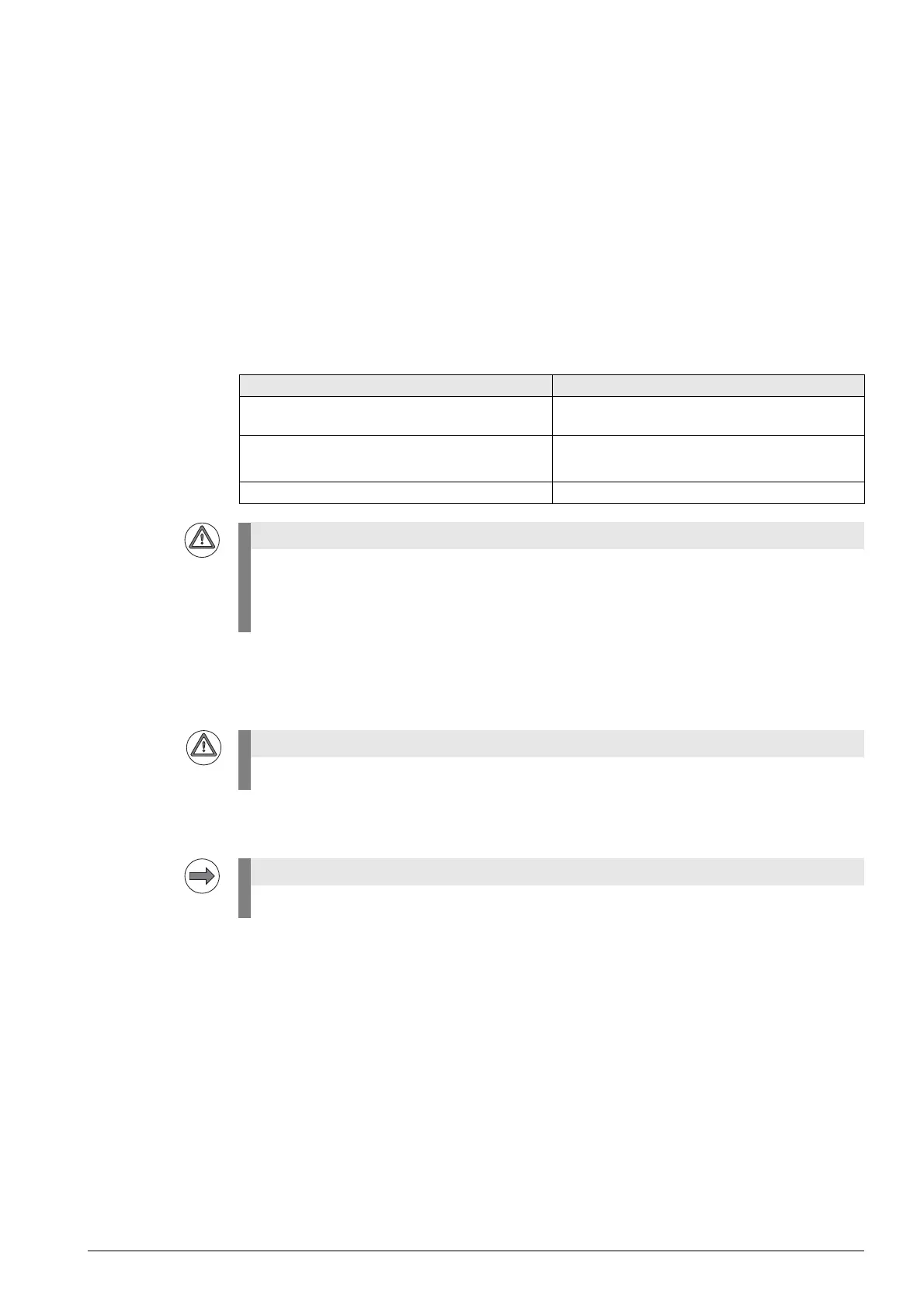

Criterion Error message

Absolute position with distance-coded reference

marks

Position encoder <AXIS> defective

Amplitude of encoder signals Position encoder <AXIS >: amplitude too high

Position encoder <AXIS>: amplitude too low

Edge separation of encoder signals Position encoder <AXIS>: frequency too high

The monitoring functions for the position encoders (MP20.x, MP21.x) must always be active!

Safe machine operation is not ensured without these monitoring functions.

Exception:

MP20.0 and MP21.0 are only active for position encoders with distance-coded reference marks.

MP100 must not be changed!

The input value (0 ... 3) represents the HSCI address of the respective controller basic board.

Loading...

Loading...