6 – 58 HEIDENHAIN Service Manual iTNC 530 HSCI

6.4 Sequence for finding errors in the control loop

In the event of error messages related to movement, acceleration or standstill, for example:

Positioning error

Excessive servo lag

Nominal speed value too high

Movement monitoring

Standstill monitoring

or if there are problems such as:

Poor workpiece quality

Unusual noise during axis movements

Unusual vibrations

... you can check the machine components in a defined order to find the fault --> See flowchart in this

chapter.

Integrated

oscilloscope

The integrated oscilloscope for iTNC 530 HSCI is a handy tool for analyzing errors in the control loop.

Activation and operation --> See ”Integrated oscilloscope” on page 10 – 95.

See also:

”Finding position differences of direct and indirect encoders” on page 6 – 67

”Error localization by switching from direct to indirect position measurement” on page 6 – 69

If you need information on lubrication, mechanics, hydraulics, pneumatics, brakes, coupling

system, please contact your machine manufacturer!

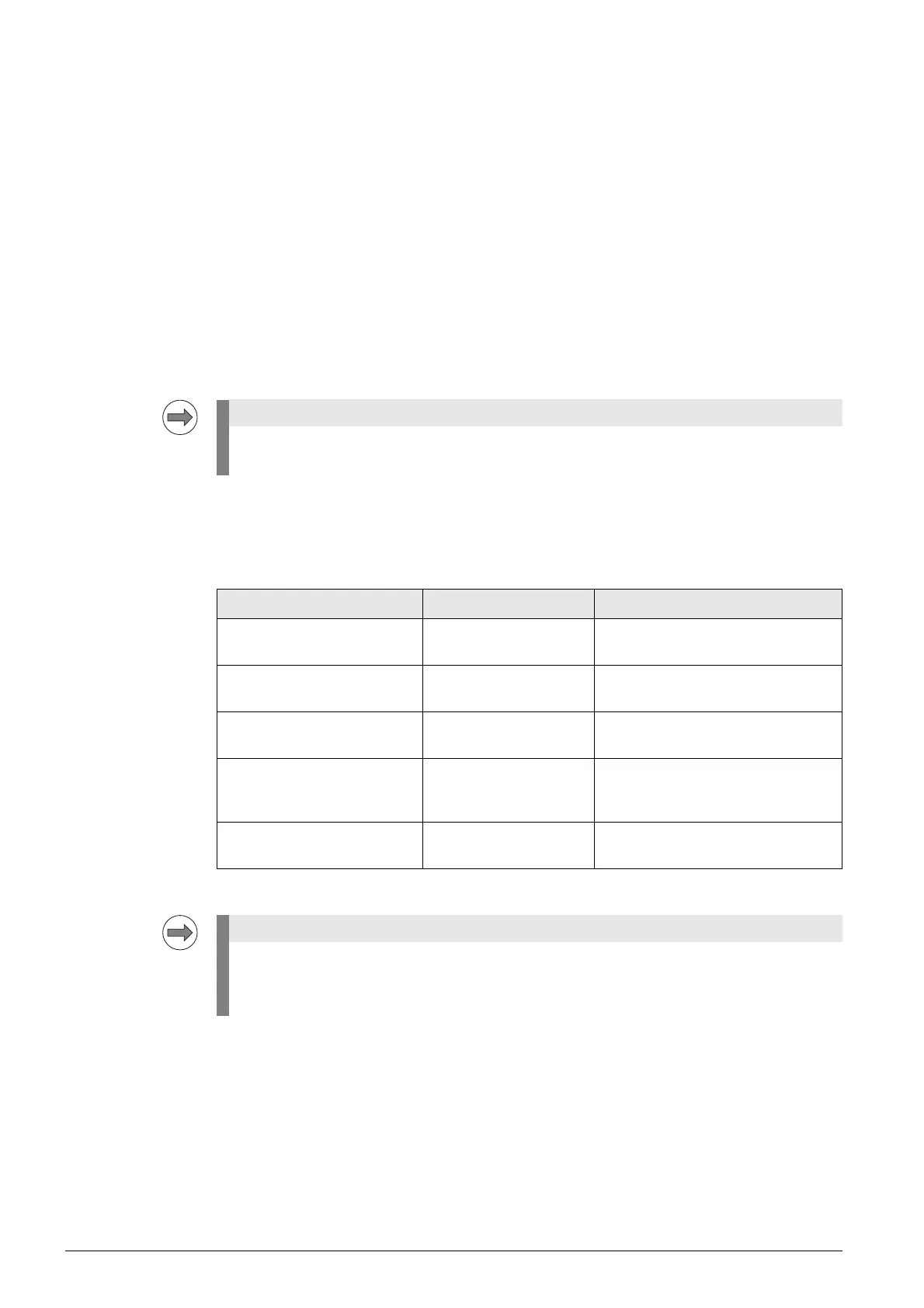

Error message Recommended signals Additional signals

Positioning error s diff I (noml), I2-t (mot.), I2-t (p.m.),

Utilization

Excessive servo lag s diff I (noml), I2-t (mot.), I2-t (p.m.),

Utilization

Nominal speed value too

high

v noml, v (n noml),

v actl, v (n actl)

I (noml), I2-t (mot.), I2-t (p.m.),

Utilization

Movement monitoring v noml, v (n noml),

v actl, v (n actl),

pos. diff.

I (noml), I2-t (mot.), I2-t (p.m.),

Utilization

Standstill monitoring s diff, s actl I (noml), I2-t (mot.), I2-t (p.m.),

Utilization

The torque-determining current I noml in particular is an important characteristic for the mechanics

of the axis concerned (stiffness, blunt tool, lubrication, utilization, etc.)

Other signals, such as I2-t (mot.), I2-t (p.m.) and Utilization are calculated from the current.

Loading...

Loading...