February 2012 6 – 69

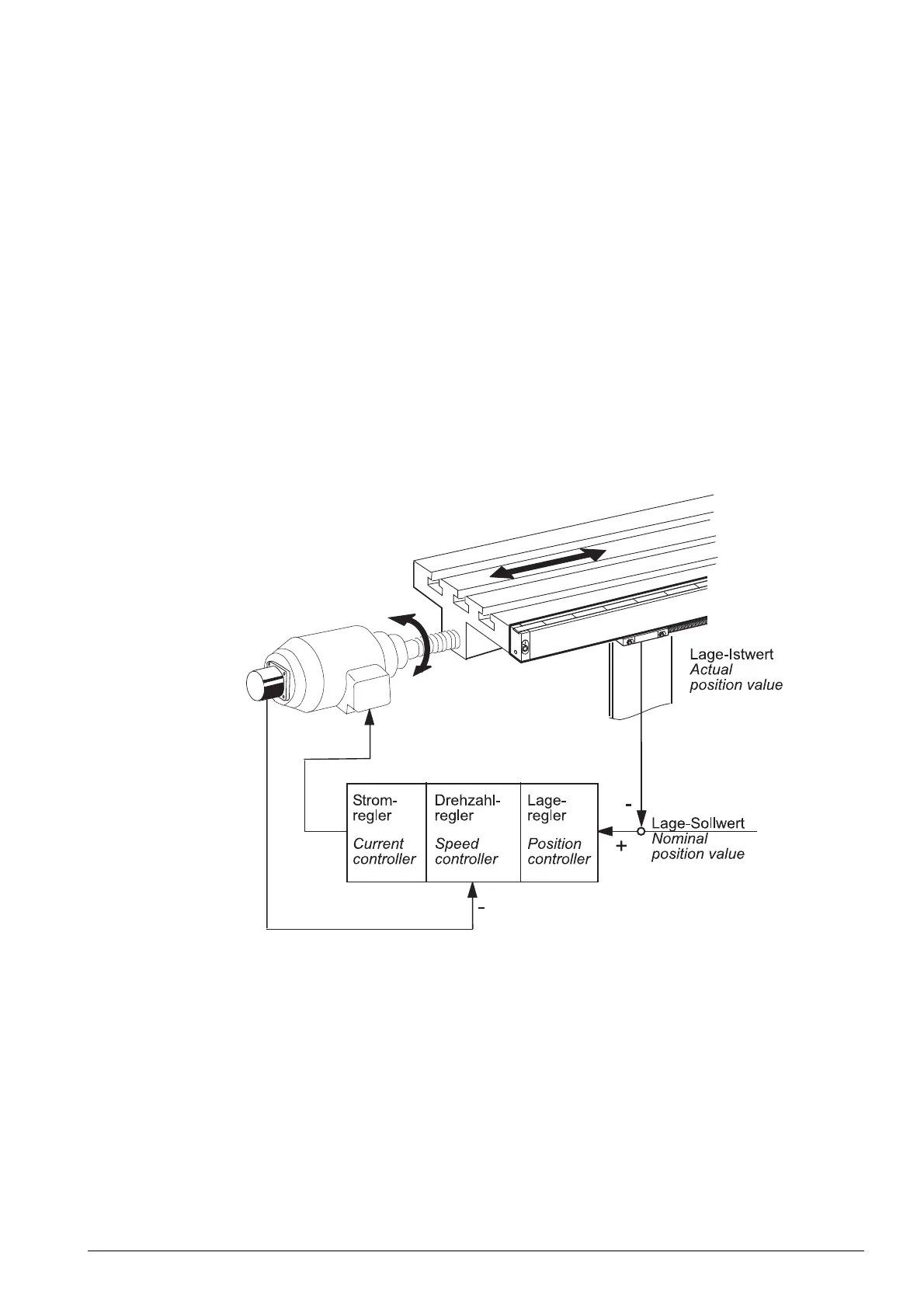

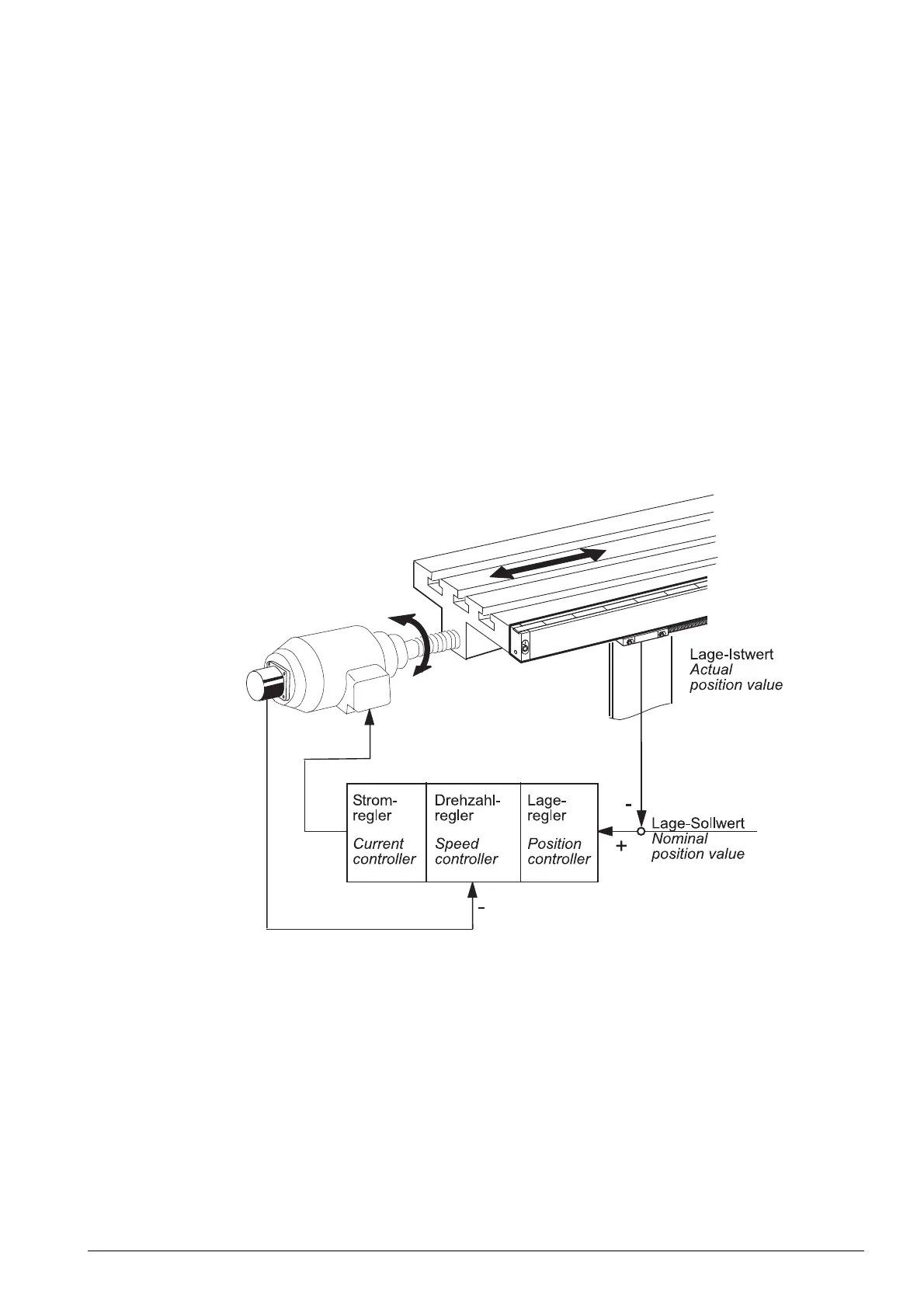

6.9 Error localization by switching from direct to indirect position measurement

With this procedure, the direct encoder (scale, scale tape, etc.) is deselected. Instead, the position is

measured with the motor encoder.

Switching to the motor encoder is useful in the following events:

The characteristics of an axis have degraded (unusual noise during traverse, poor surface quality,

controller oscillations, etc.)

Errors occur that do not clearly refer to an encoder or the mechanics of an axis.

Prerequisite The machine tool to be investigated must be equipped with digital drives and direct encoders

(dual encoder system).

These instructions do not apply for digital axes with linear motors.

Direct position

measurement

With direct position measurement, couplings and transmission systems (belts, gears, etc.), ball screw

with recirculating ball nut and guideways are part of the control loop.

Deteriorations of these components may have a negative effect on the control loop.

Loading...

Loading...