120

3.6 Adjusting the Peel-Detection Rollers

REGIUS MODEL 190 Service Manual Ver.1.00 2004.11.01

3.6.2

Adjustment of the Standard Position

The peel detection roller is to be fixed at the standard position

where it comes into contact with the peel detect roller jig.

1.

Move the power-supply breaker to the OFF position.

2.

Remove the rear cover. ("2.2.1 Removal of the Rear

Cover", p.28)

3.

Remove the left and right side covers. ("2.2.2 Removal of

the Left & Right Covers", p.29)

4.

Open the front door.

5.

Manually raise the balance weight to bring the cassette

magnetizing plate to the bottom.

6.

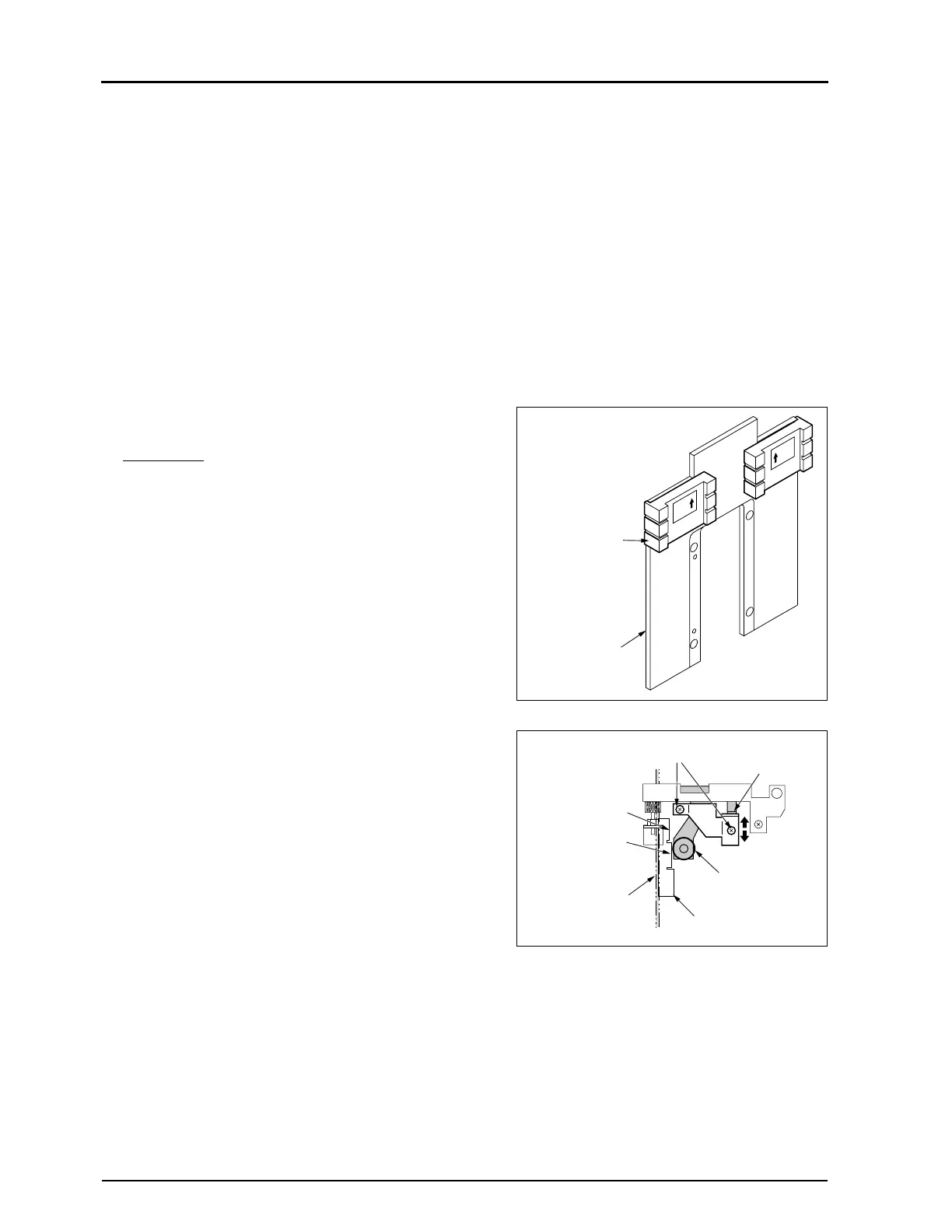

Attach the peel detect roller jig to the both corners of top

edge of the magnetizing plate.

Impor

tant Attach the jig with its arrow pointing

upward.

7.

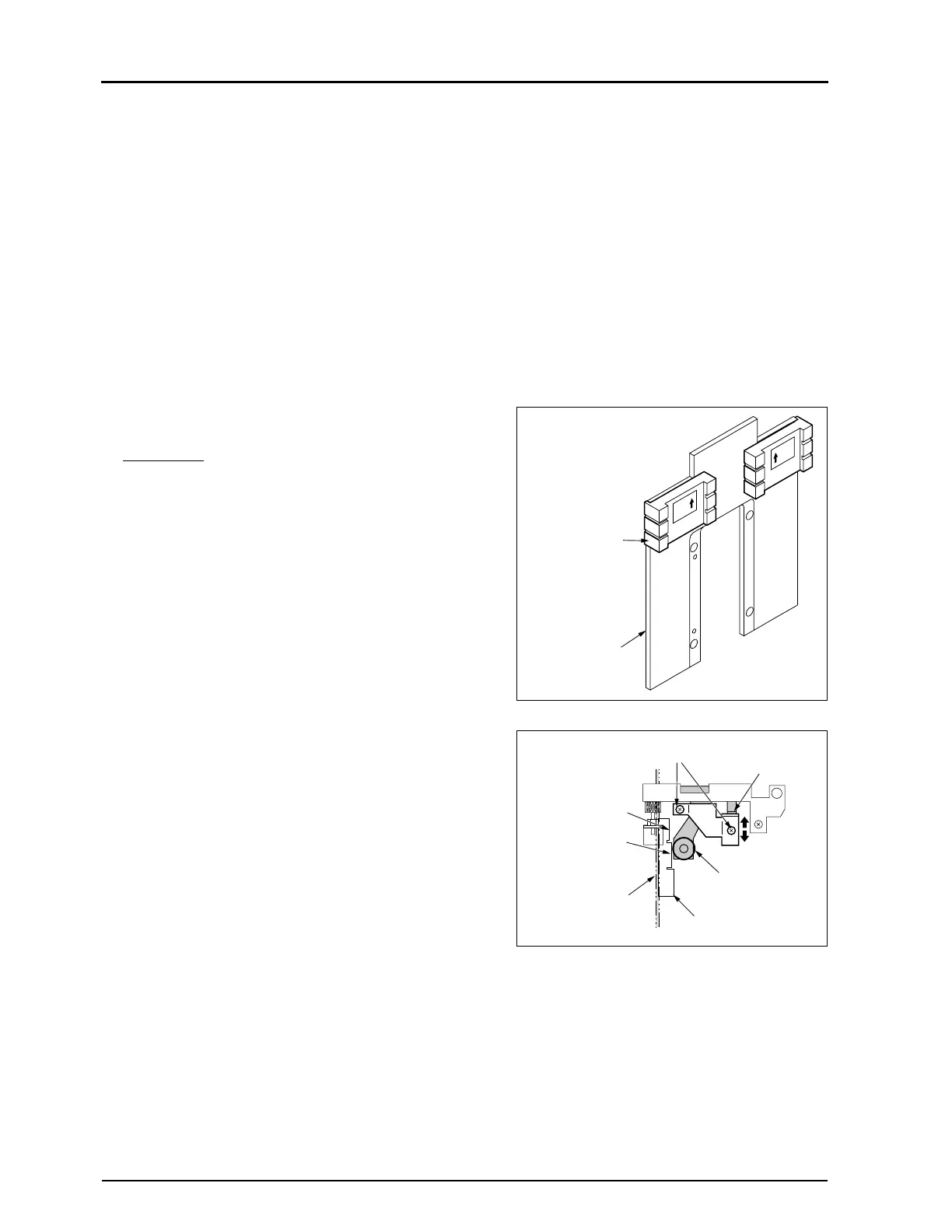

Loosen two fixing screws "a".

• It is possible to start at either the left or right side.

8.

Slowly lower the balance weight until the peel detection

roller comes into contact with thinner part of the peel detect

roller jig.

9.

Confirm the following and then tighten the fixing screws "a".

• When the peel detect roller jig ascends, the peel detec-

tion roller should not contact with verification part of the

peel detect roller jig.

• The peel detection roller should contact with thinner part

of the peel detect roller jig.

• The peel detection cam should contact with the pro-

jected part of peel detect arm.

10.

In the same way as above, adjust the peel detection mech-

anism on the opposite side.

11.

Proceed to "3.6.3 Adjustment of the Sensor Detect

Position, p.121"

Left

Right

Peel Detection

Roller Test Jig

Magnetizing

Plate

Projected Part

Peel Detect Roller

Magnetizing Plate

Thinner Part

Verification Part

Peel Detect Roller Jig

Fixing Screw "a"

Loading...

Loading...