27

2.1 Preparation for Disassembly

REGIUS MODEL 190 Service Manual Ver.1.00 2004.11.01

2.1 Preparation for Disassembly

2.1.1 Precautions for Disassembly and Reassembly

Caution Be sure to observe the following precautions

whenever performing disassembly or reassembly

on this device. Note that failure to do so may lead

to personal injury or damage to equipment.

• In order to protect against electric shocks, always

confirm that the supply of power has been turned

off before starting disassembly or reassembly.

Please also turn off the REGIUS 190's circuit

breaker or the facility's breaker.

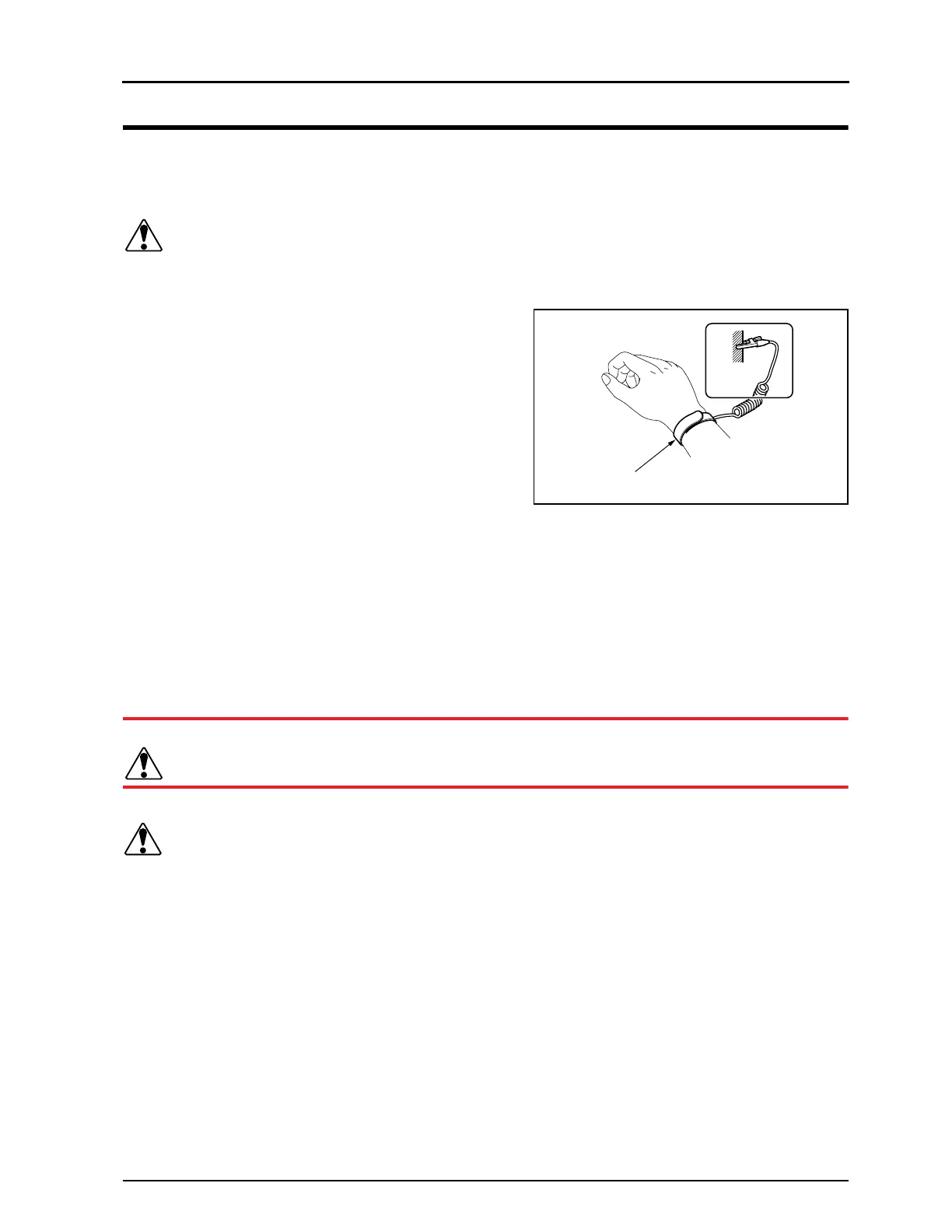

• If printed circuit boards are to be handled, be sure

to secure an earth strap to your wrist and to attach

the clip end to a grounded section of the device.

• An earth strap must be worn to protect circuits

from damage.

• During reassembly, be sure to return wire bundles

to their original condition and to confirm that they

have not become trapped between, or caught on

components.

• Sensors are still electified even after the interlock

has been disengated. Be careful not to short-cir-

cuit the sensors.

Except for the work to replace the decelerating steel belt

unit ("2.5.3 Steel Belt Decelerating Unit, p.68"), no work is

necessary to touch the steel belt.

Danger Never touch the steel belt directly by hand. The hand or fingers may be cut due to the sharp

edge of the steel belt.

Caution If the fat of hand remains on the steel belt, rust may develop, and it may cause malfunction of

the subscan operation.

• Note for the anti-slip rubber on the justification assy

Do not touch the antislip rubber on the justification assy. Soiling

the rubber with finger fat may develop adhesion, and adversary

affects the separating process of cassette (especially mammo

cassette). Should the fat sits on the rubber, clean it with alco-

hol. However, note that the rubber has to be left untouched for

minimum of 2 days in the case an alcohol is applied. When the

new antislip rubber is available, replace it with a new one.

Earth strap

Loading...

Loading...