142

4.3 Troubleshooting for Image Quality

REGIUS MODEL 190 Service Manual Ver.1.00 2004.11.01

4.3.6 Case 5: Vertical Lines

Phenomena Cause/Remedy

1 Sharp white lines

(5 to 10 pixels in width)

1) If there are horizontal scratches on the

plate;

1)Replace the plate.

2) If dust has collected on the edge of the

optical unit's beam-condensing section

and the laser is disturbed;

2) Blow clean the edge of the optical unit's beam-condens-

ing section. At this time, visually check whether dust is

present between the excitation light's cut filter and the

condensing mirror, and then perform blower cleaning and

confirm that the dust has been removed. Note that the

location of dust adherence can be estimated from the

position of the vertical lines in the image. (The service

tool's left side corresponds to the right side of the con-

densing mirror.

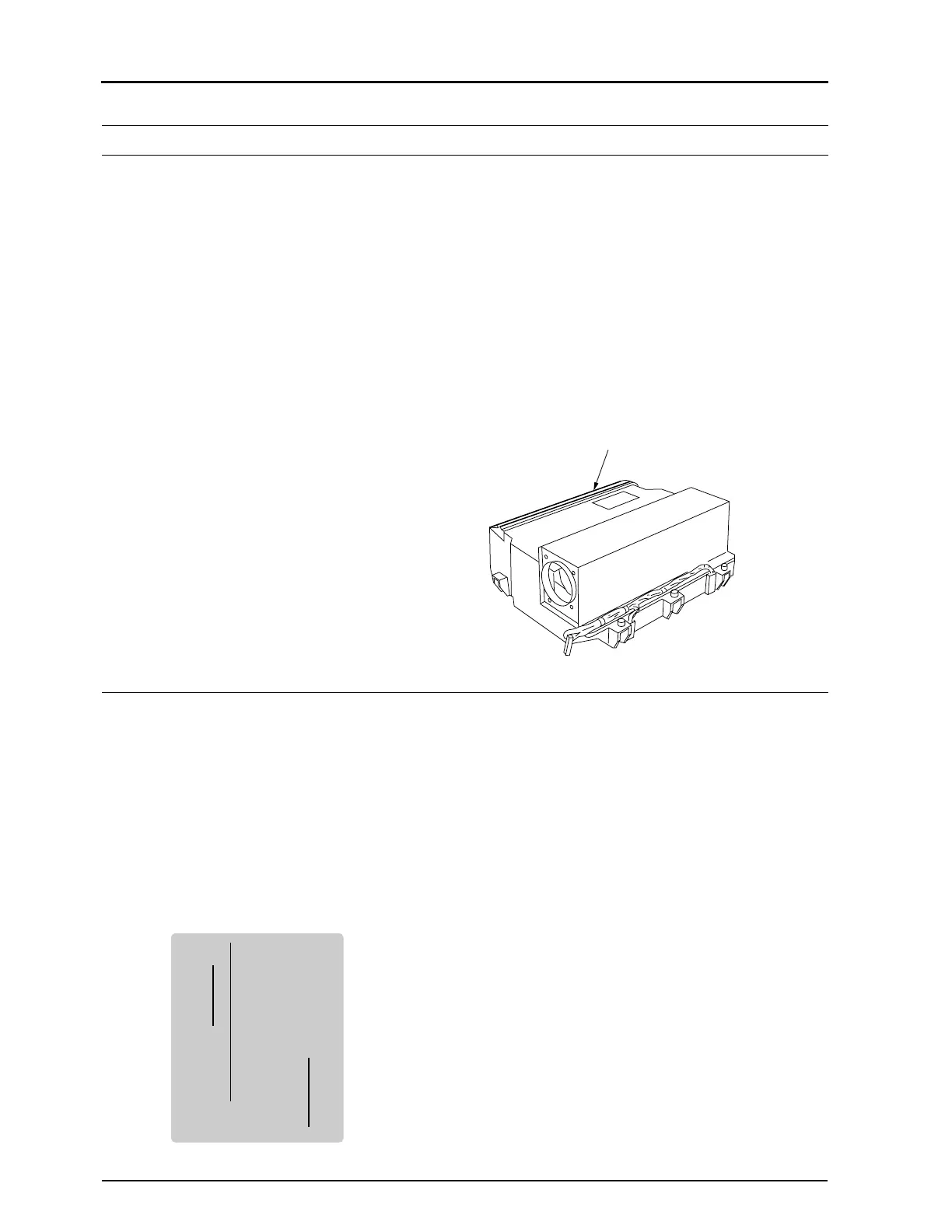

2 Sharp black lines

(5 to 10 pixels in width)

1) Lines disappear when exposure is per-

formed without correction.

1) Redo irregularity correction using a plate which is free of

scratches. If vertical, localized black stripes occur in low

dosage images as in the diagram on the right and they do

not re-appear in high-dosage images;

2) This defect is caused if irregularity cor-

rection is carried out when either the

plate is scratched or when dust is present

on the edge of the optical unit's beam

condensing section.

2) Excitation light is leaking and the optical unit should be

replaced. "2.6.2 Replacement of Optical Unit, p.76"

Cut Filter for Exitation Light

Loading...

Loading...