Troubleshooting Guide

SM Appendix 6-3 D037/D038/D040/D041

Appendix:

Trouble-

shooting

Guide

6.1.2 LINE POSITION ADJUSTMENT

When there are color registration errors on the output, do the line position adjustment as

follows.

Use A3/DLT size paper for this adjustment.

Test

1. Do SP2-111-003 (Mode c: rough adjustment).

2. Use SP2-194-007 to check if the result of the line position adjustment is correct (0:

Completed successfully, 1: Not completed). If the result is "1", refer to ‘Countermeasure

list for color registration errors’.

3. Do SP2-111-001 (Mode a: fine adjustment twice).

4. Use SP2-194-007 to check if the result of the line position adjustment is correct (0:

Completed successfully, 1: Not completed). If the result is "1", refer to ‘Countermeasure

list for color registration errors’.

5. Put some A3/DLT paper on the by-pass tray.

When you print a test pattern, use the by-pass tray to feed the paper.

6. Print out test pattern "7" with SP2-109-003.

7. Check the printed output with a loupe.

8. If there are no color registration errors on the output, the line position adjustment is

correctly done. If not, refer to the countermeasure list for color registration errors.

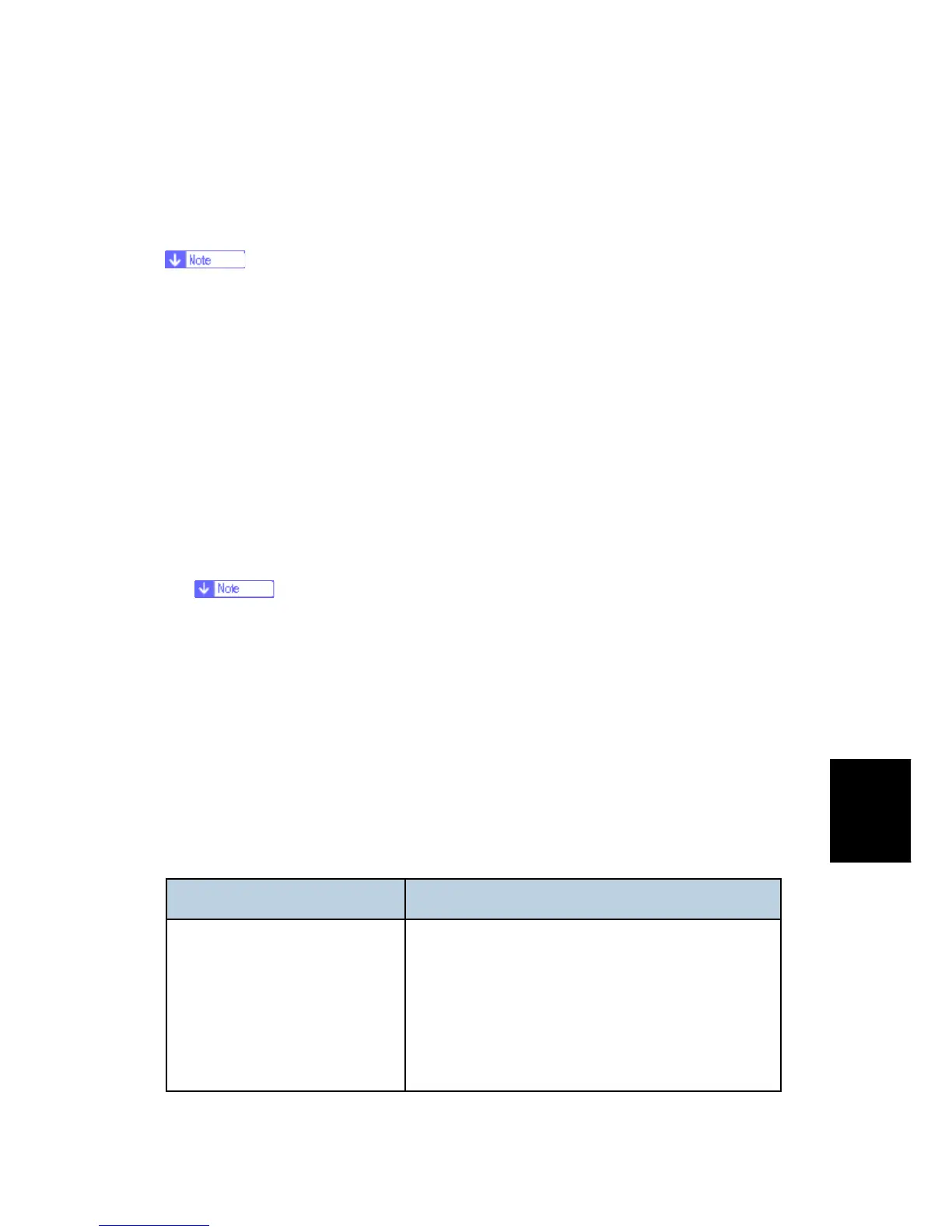

Countermeasure list for color registration errors

After Executing SP2-111-003

Result: "1" in SP2-194-007

Result: "2" or "3" (Line pattern detection failure) in SP2-194-010, -011, -012

Test pattern check Possible cause/Countermeasure

White image, Abnormal image,

Low density

Defective image processing unit

Low density of test pattern

Defective i-controller

1. Replace the high voltage power supply unit.

2. Do the forced process control (SP3-011-001) or

supply some toner (SP3-015-xxx).

Loading...

Loading...