Oil Pump Strainer

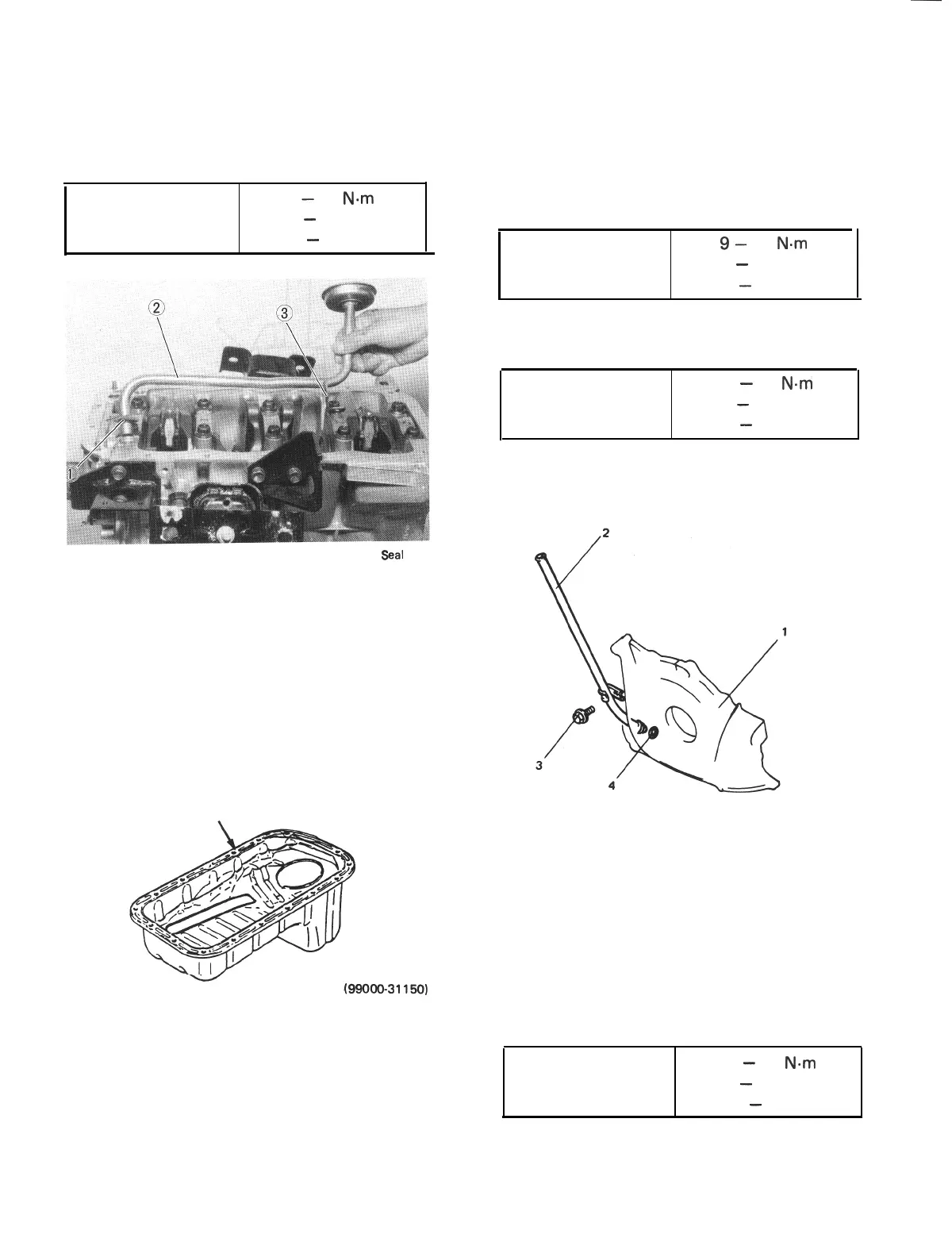

Install seal in the position shown in Fig. 3-6-22.

Tighten strainer bolt first and bracket bolt to

specified torque.

Tightening

torque

9

-

12

N.m

0.9

-

for bolts

1.2 kg-m

6.5

-

8.5 lb-ft

Fig. 3-6-22 Installing seal

1.

Seal

2. Strainer

3. Bracket

Oil Pan

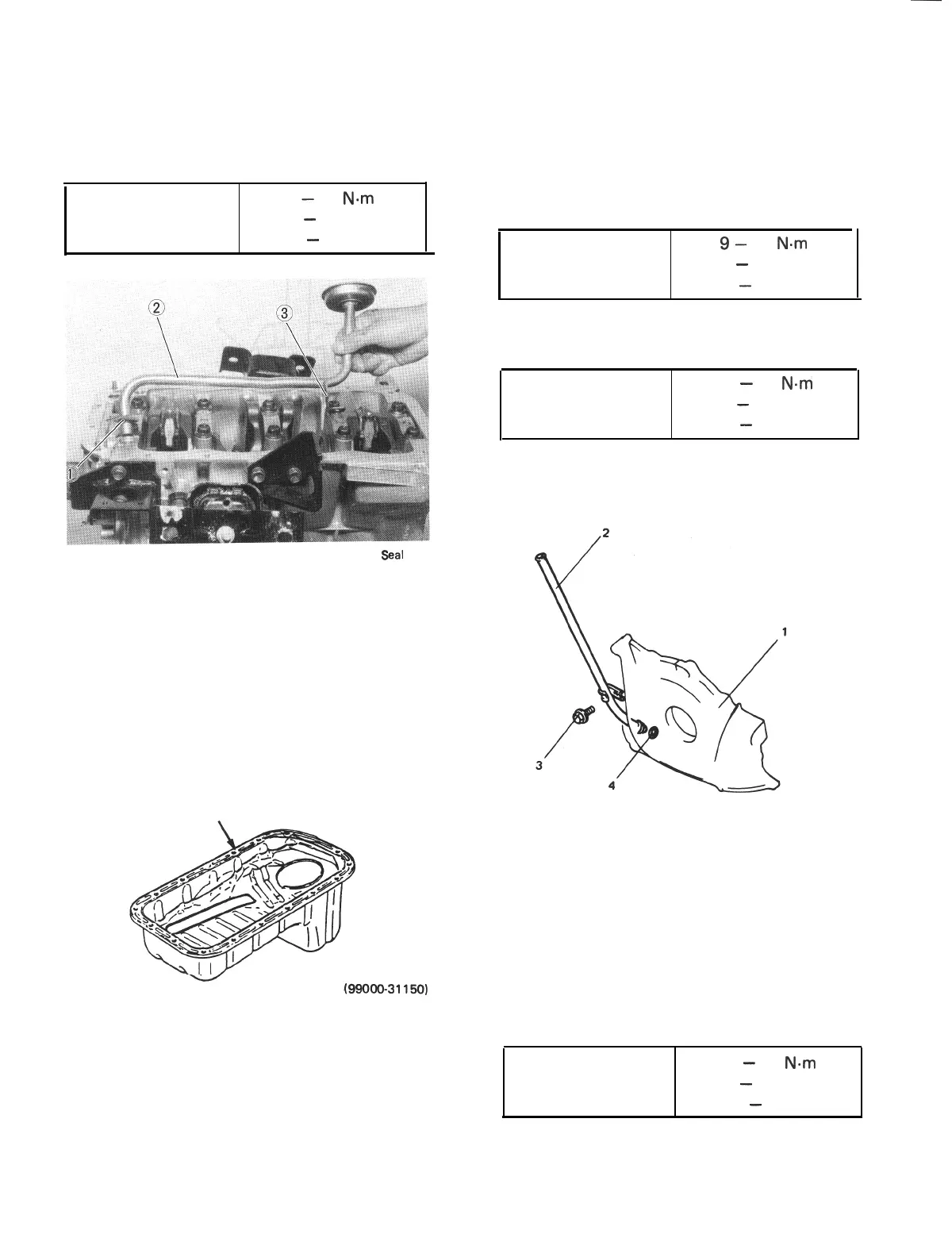

1) Clean mating surfaces of oil pan and cylinder

block. Remove oil, old sealant, and dusts

from mating surfaces.

After cleaning, apply silicon type sealant to

oil pan mating surface continuously as

shown in Fig. 3-6-23.

Sealant

MOOO-31150)

Fig. 3-6-23 Applying sealant to oil pan

2) Install oil pan to cylinder block.

After fitting oil pan to block, run in secur-

ing bolts and start tightening at the center:

move wrench outward, tightening one bolt

at a time.

Tighten bolts to specified torque.

Tightening

torque

9-

12

N-m

-

for oil pan

bolts

0.9

1.2 kg-m

7.0

-

8.5 lb-ft

3) Install gasket and drain plug to oil pan.

Tighten drain plug to specified torque.

Tightening torque

for drain plug

30

-

40

N.m

3.0

-

4.0 kg-m

22.0

-

28.5 lb-ft

4) Install guide seal to pump case and then oil

level gauge guide.

1. Oil pump

2. Oil level gauge guide

3. Guide bolt

4. Guide seal

Fig. 3-6-24 Oil level gauge guide

Flywheel

Install flywheel to crankshaft.

Using special tool, lock flywheel, and tighten

flywheel bolts to specification.

Tightening torque

for flywheel bolts

57 65

N-m

-

5.7 6.5 kg-m

-

41.5

-

47 lb-ft

3-42

Loading...

Loading...