Rocker-Arm Shaft and Rocker Arms

0

Shaft-to-arm clearance (IN & EX):

Using a micrometer and a bore gauge, measure

The difference between two readings is the

specified.

If the limit is exceeded, replace shaft or arm,

I

Item

Standard Limi t

I

Rocker arm 16.000

-

16.018 mm

I.D. (0.629

-

0.630 in.)

Rocker arm 15.973

-

15.988 mm

Shaft dia. (0.628

-

0.629 in.)

Arm-to-Shaft 0.012

-

0.045 mm 0.08 mm

clearance (0.0005

-

0.0017 in.) (0.0035 in.)

Fig. 3-5-6

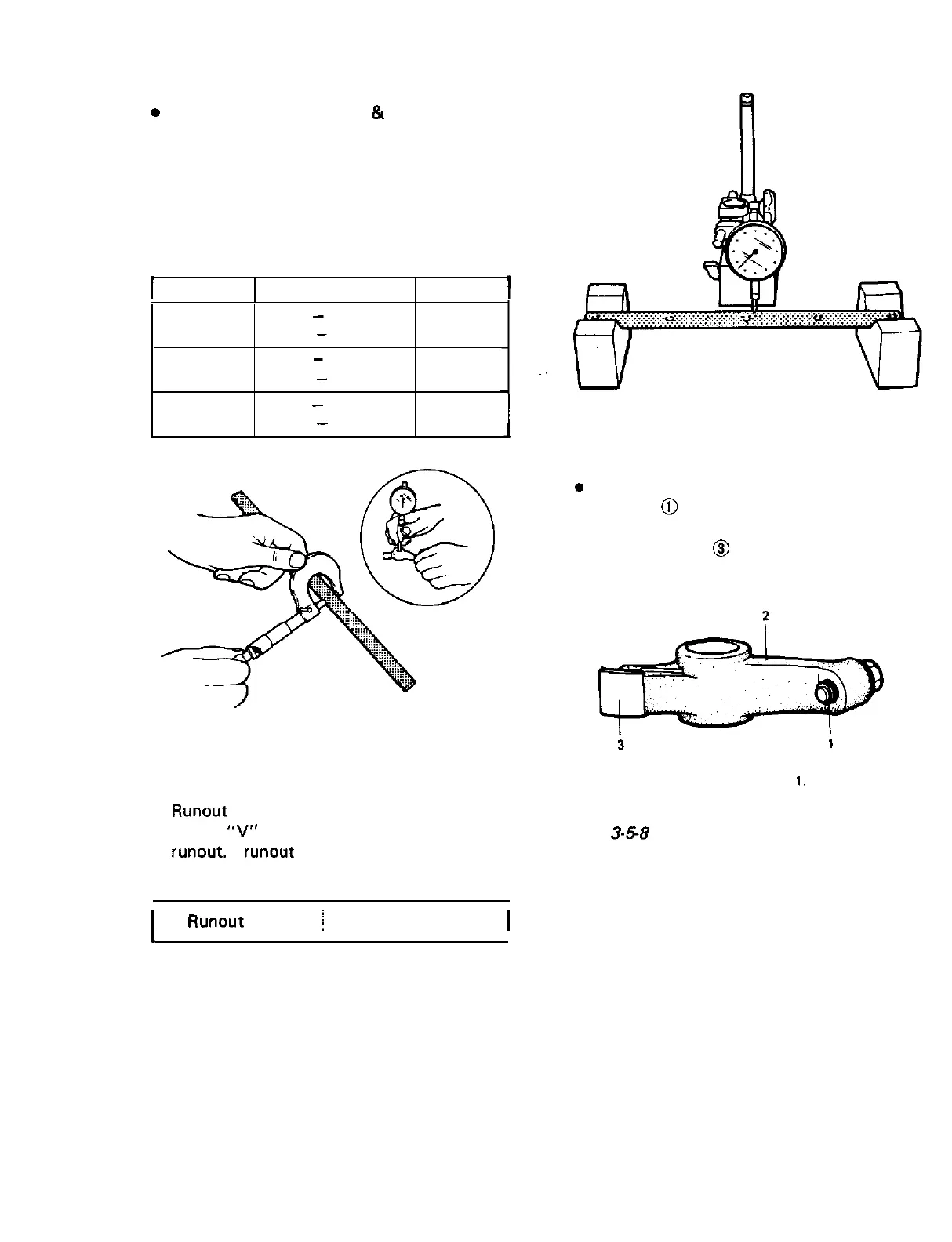

l Runout of rocker-arm shaft:

Using

“V”

blocks and dial gauge, check

runout. If

runout

exceeds the limit, replace

rocker arm shaft.

I

Runout limit

I

1

0.12 mm (0.004 in.)

1

I

I

Fig. 3-5-7

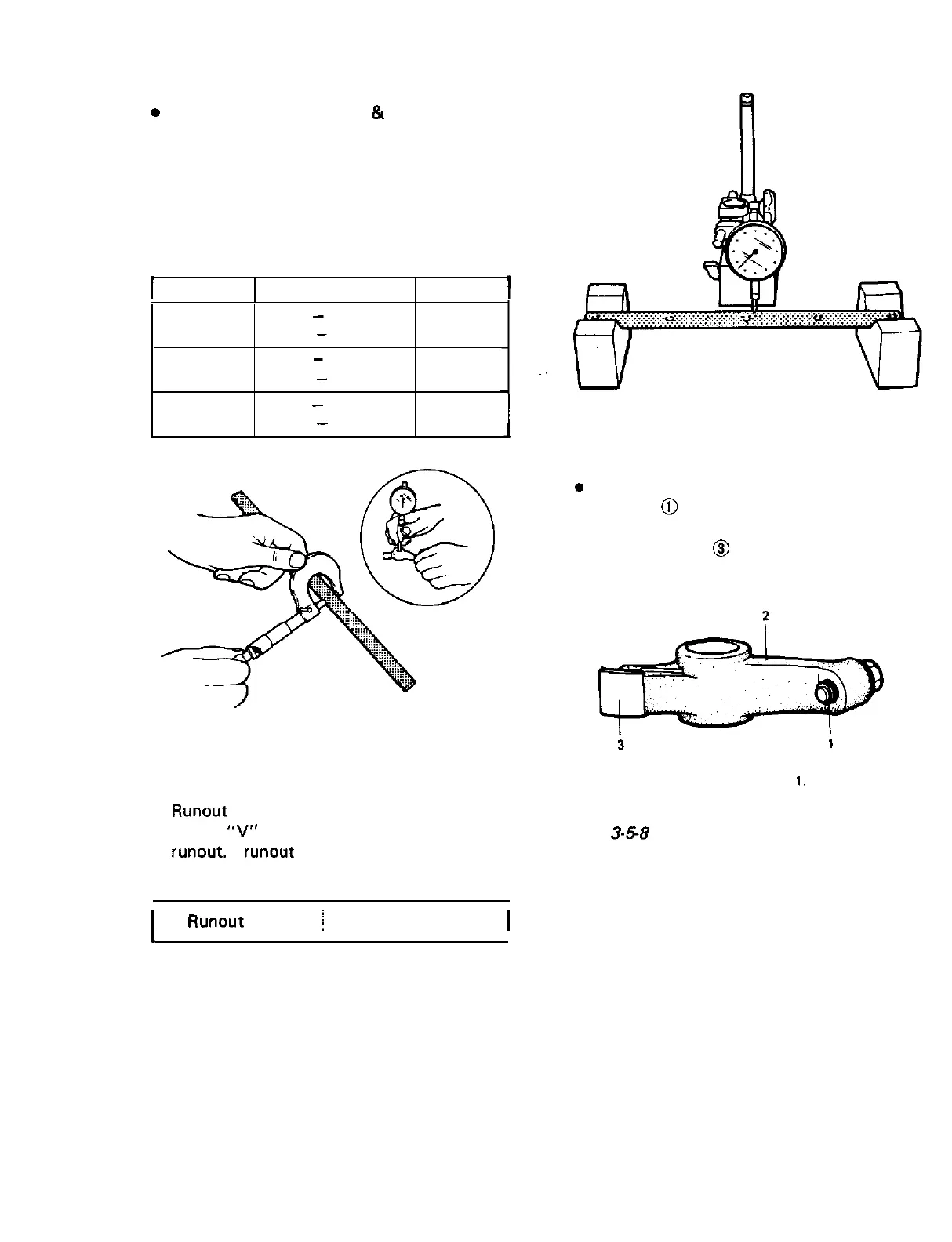

0

Wear of rocker-arm and adjusting screw:

If the tip

@

of adjusting screw is badly worn,

replace screw. Arm must be replaced if its

cam-riding face

@I

is badly worn.

1.

Adjusting screw

2. Rocker arm

3. Cam-riding face

Fig. 3-5-8

Valve Guides

Using a micrometer and bore gauge, take dia-

meter readings on valve stems and guides to

determine stem clearance in guide. Be sure to

take a reading at more than one place along

the length of each stem and guide.

3-19

Loading...

Loading...