[Bi-metal vacuum switching valve (BVSV)]

NOTE:

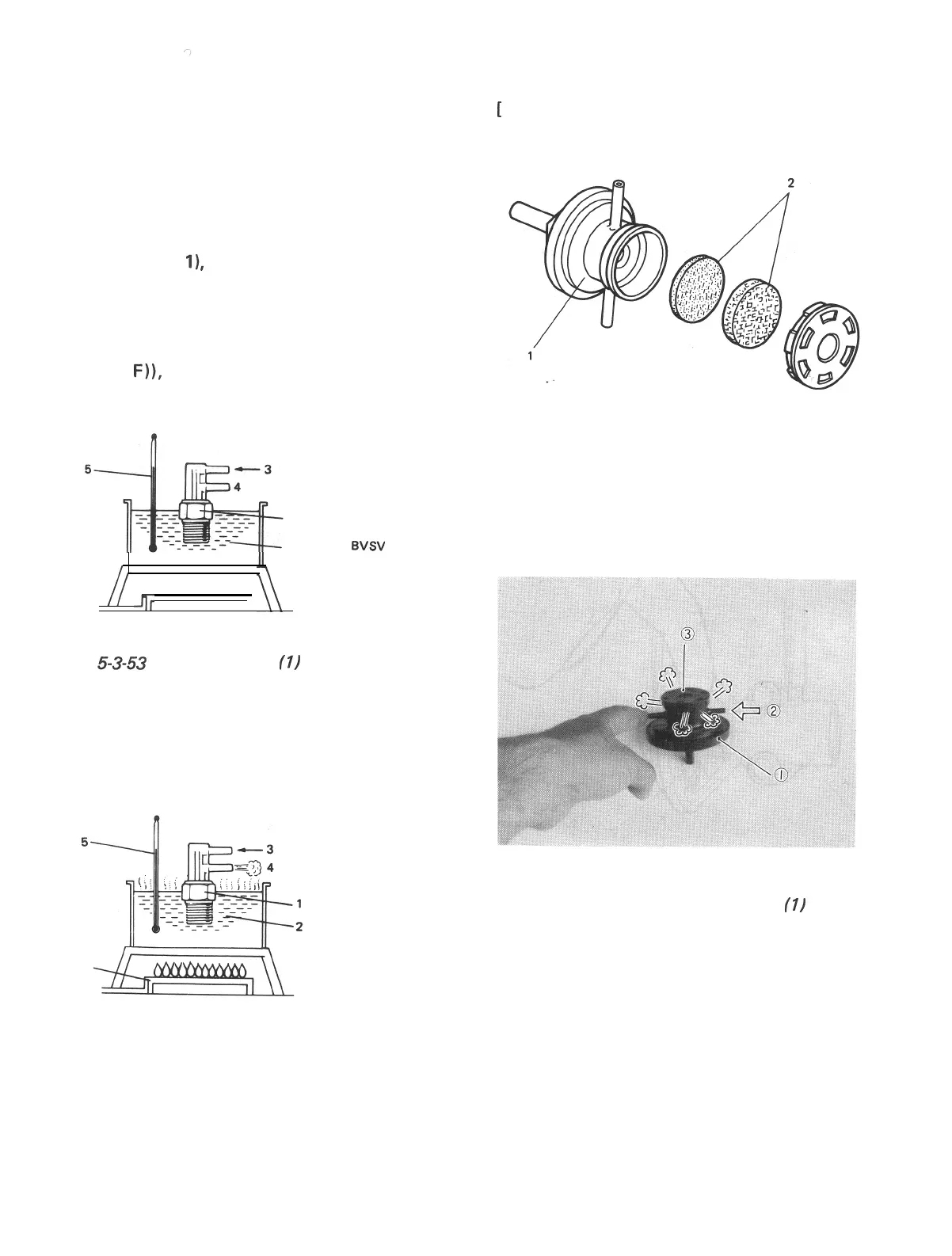

For the rough check of the operation, BVSV

can be checked by warming up or cooling down

the engine without being removed from the

intake manifold.

The check procedure is the same as the follow-

ing except item

11,

2) and 5).

1) Drain cooling system when engine is cold.

2) Disconnect vacuum hoses and remove BVSV

from intake manifold.

3) While keeping BVSV cool (below 53°C

(127”

F)),

blow nozzle “3”. Air should not

come out of nozzle “4”.

1

2

I

Jlr

II

Fig.

5-3-53

Checking B VSV

11)

4)‘While keeping BVSV warm

1.

BVSV

2. Cool water

3. Blow air

(nozzle)

4. “No air”

(nozzle)

5. Thermometer

(above 65” C

(149°F)) in hot water, blow nozzle “3”.

Air should come out of nozzle “4”.

6

Fig. 5-3-54 Checking B VSV (2)

[

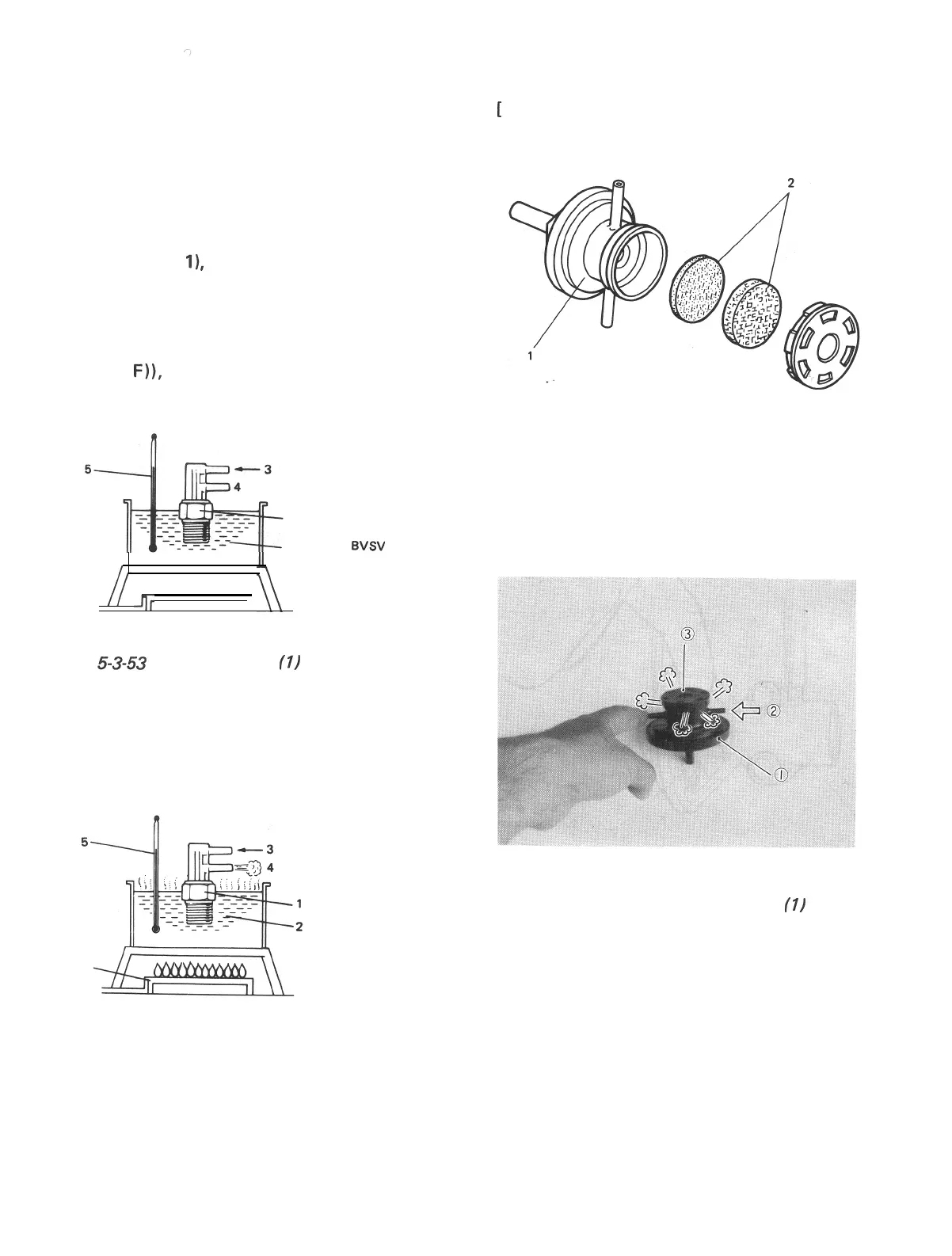

EG R modu latorl

1) Check filter for contamination and damage.

Using compressed air, clean filter.

1. EGR modulator

2. Filter

Fig. 5-3-55 Filter of EGR modulator

2) Remove EGR modulator and plug nozzle

with your finger. Blow air into another nozzle

and check that air passes through to air

filter side freely.

1. EGR modulator

2. Blow air

3. Air filter

Fig. 5-3-56 Checking EGR modulator (1)

1.

BVSV

2. Hot water

3. Blow air

(nozzle)

4. Air (nozzle)

5.

Thermometer

6.

Heater

5) Reinstall BVSV to intake manifold. Before

installing, wind sealing tape on its thread.

6) Connect vacuum hoses.

5-38

Loading...

Loading...