Gear Shift Shafts

Check the part of shaft as indicated in below

figure for uneven wear. Replace shaft if uneven

wear is noted.

Fig. 13-40

Extension Case Bush

Check bush press-fitted in extension case for

wear by measuring radial clearance between

bush bore and sliding yoke. If sliding yoke

rattles in bush because of advanced wear it will

cause propeller shaft to rattle. For this reason,

an extension case found to allow its sliding

yoke to rattle in excess of service limit must be

replaced; replacement of bush alone is not

permissible.

Rattle of

sliding yoke

c

in extension

case bush

Standard

1

Service limit

0.025

-

0.089 mm

0.2 mm

(0.0010

-

0.0035 in.)

(0.0078 in.)

I

I

I

13-6. IMPORTANT STEPS IN

INSTALLATION

NOTE:

l

Before installation, wash each part and apply

specified gear oil to sliding faces of bearing

and gear.

l

Use new circlips on shaft for reinstallation.

Don’t reuse used circlips.

l

Tighten each fastening bolt and nut according

to specified torque data listed on the last

page of this section.

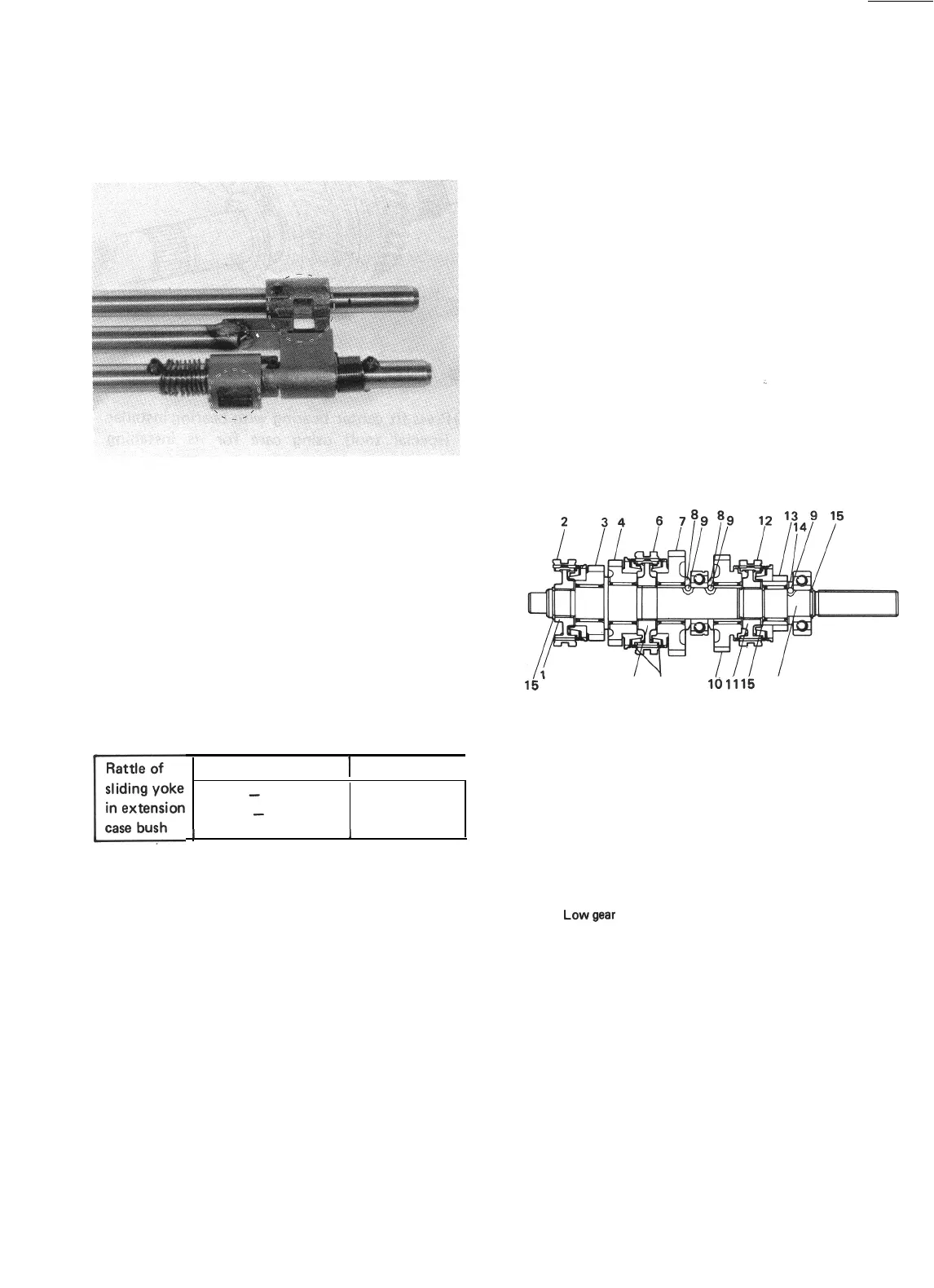

Main Shaft and Input Shaft

:,

Install each parts by reversing respective removal

procedures. Be careful for installing direction of

each washer, gear, synchronizer hub and sleeve.

Refer to figure below. Make sure to install each

ball on main shaft.

5 17

la

1.116

16

1. High speed synchronizer

hub

2. High speed synchronizer

sleeve

3. 3rdgear

4.

2ndgear

5. Low speed synchronizer

hub

6. Low speed synchronizer

sleeve

7.

Lowgear

6.

Washer

9.

Ball

10.

Reverse gear

11. Reverse synchronizer

hub

12.

Reverse synchronizer

sleeve

13.

5th gear

14. 5th gear washer

15. Circlip

16.

Main shaft

17.

Spring

Fig. 13-4 1

13-15

Loading...

Loading...