c

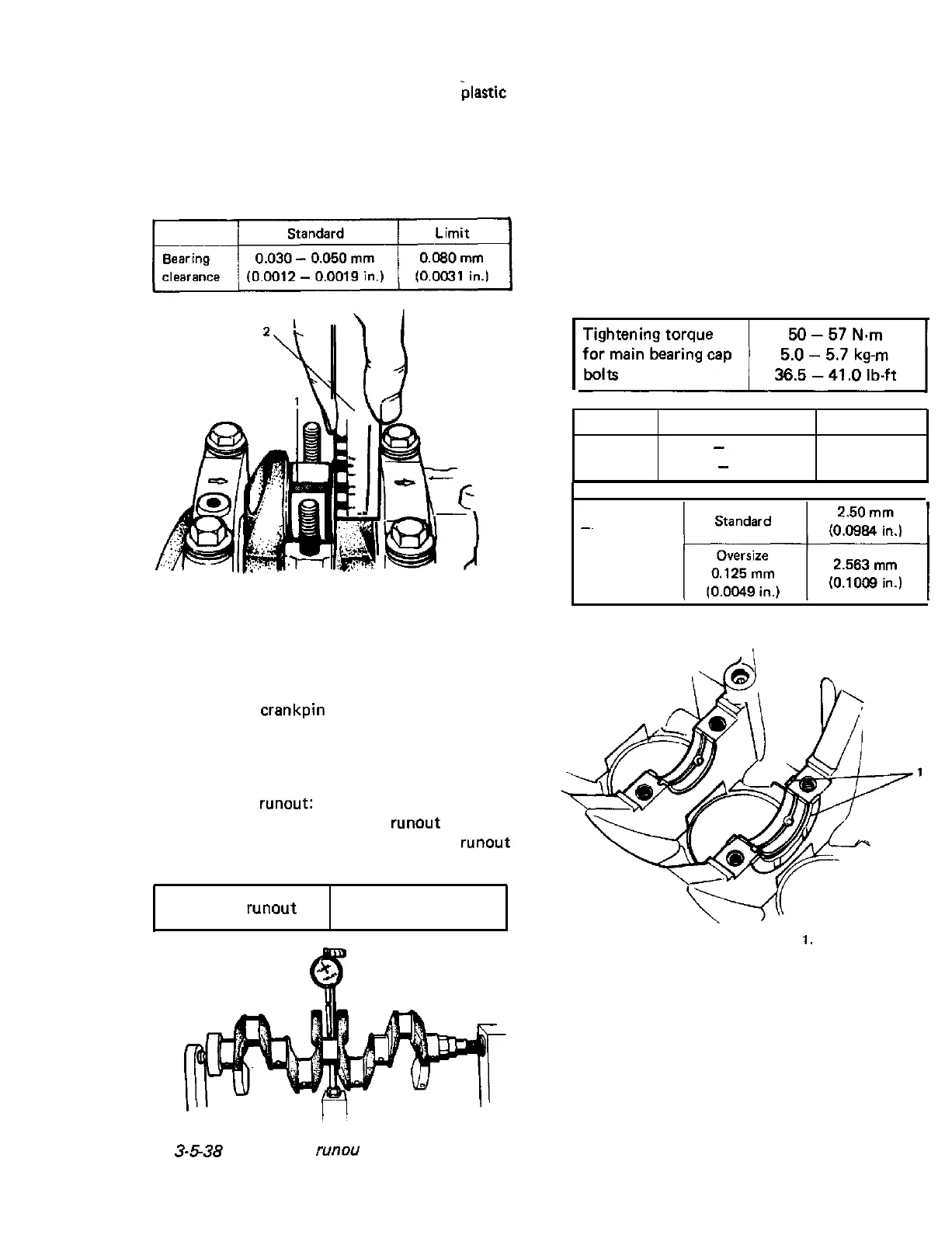

5) Remove cap and using scale on gaging

bIastic

envelope, measure gaging plastic width at

the widest point.

If the clearance exceeds its limit, use a new

standard size bearing and remeasure clea-

rance.

1. Gaging plastic

2. Scale

Fig. 3-5-37 Measuring rod bearing clearance

6) If clearance can not be brought to within

limit even by using a new standard size bear-

ing, regrind crankpin to the undersizeand use

0.25 mm undersize bearing.

Crankshaft

l

Crankshaft runout:

Using a dial gauge, measure

runout

at center

journal. Rotate crankshaft slowly. If runout

exceeds limit, replace crankshaft.

Limit on runout 0.06 mm (0.0023 in.)

l

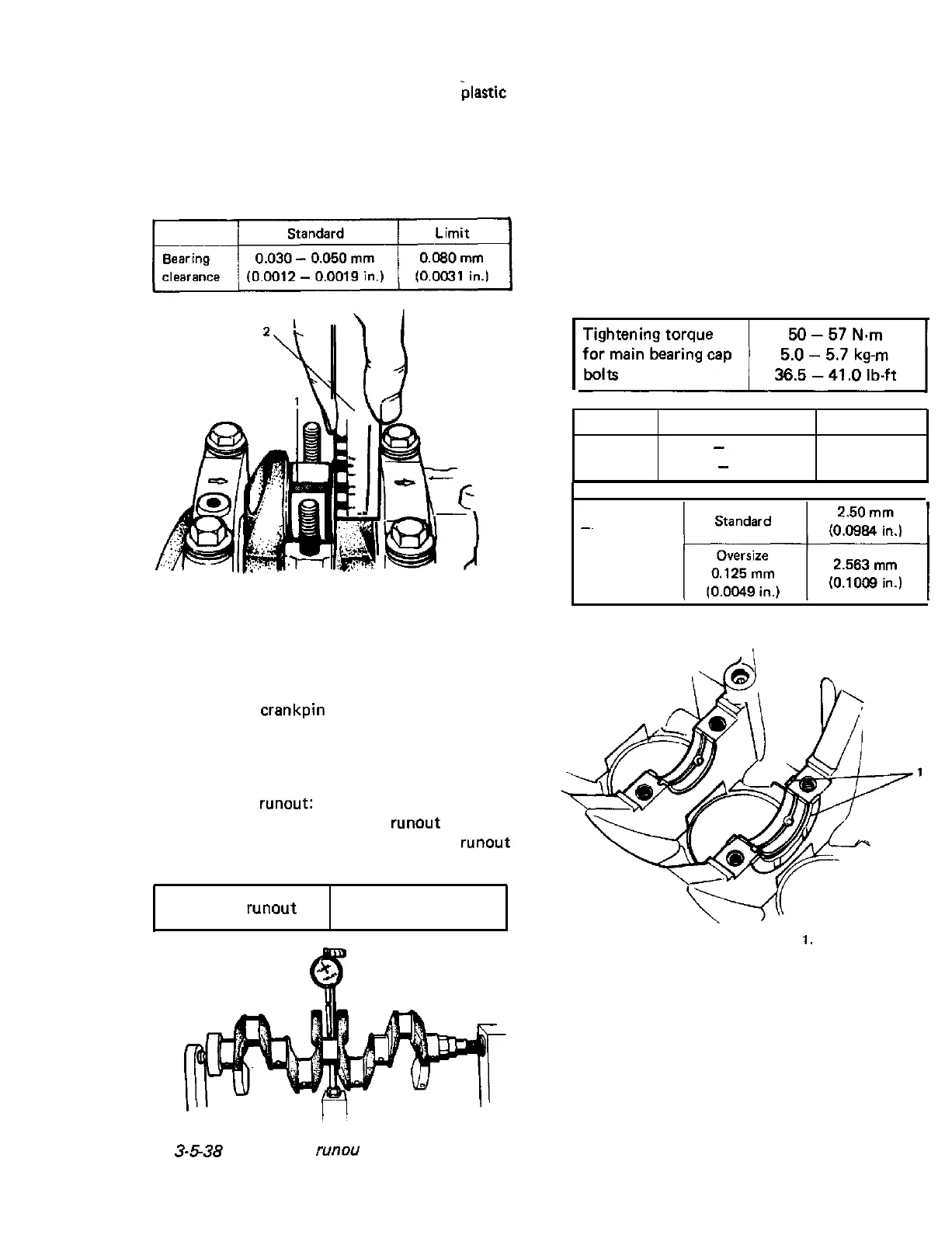

Crankshaft thrust play :

Measure this play with crankshaft set in

cylinder block in the normal manner, that is,

with thrust bearing fitted and journal bearing

caps installed. Tighten bearing cap bolts to

specified torque.

Use a dial gauge to read displacement in axial

(thrust) direction of crankshaft.

If the limit is exceeded, replace thrust bearing

with new standard one or oversize one to

obtain standard thrust play.

Item

Standard

Limit

Crankshaft

0.11

-

0.31 mm

0.38 mm

thrust play

(0.0044

-

0.0122 in.)

(0.0149 in.)

-.

Thickness of

crankshaft

thrust bearing

1,

Thrust bearing

Fig. 3-5-39 Thrust bearings

Fig.

3-5-38

Measuring runou t

3-29

Loading...

Loading...