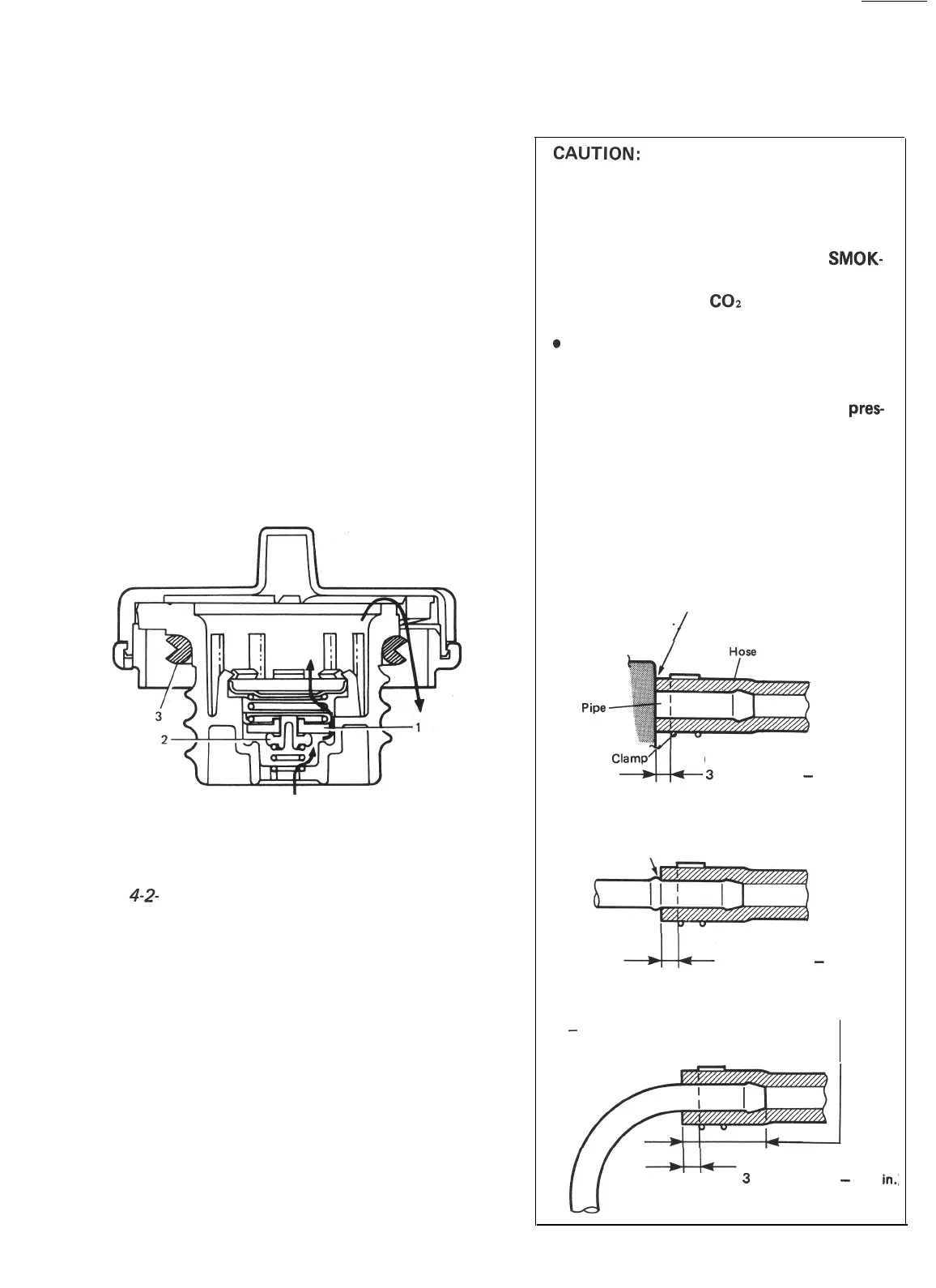

Fuel Filler Cap

The fuel tank filler neck has a pressure-vacuum

cap.

A ratchet tightening device on the threaded fuel

filler cap reduces the chances of incorrect

installation, which would prevent sealing fuel

vapors.

After the gasket on fuel filler cap and the filler

neck flange contact, the ratchet produces a

loud clicking noise, indicating the seal has been

set.

This cap has pressure relief valve and vacuum

relief valve inside.

If the pressure of fuel vapor in fuel tank should

exceed that for which fuel system is designed,

the pressure relief valve opens to relieve the

pressure.

The vacuum relief valve opens to relieve the

vacuum created in fuel tank.

1. Pressure relief valve

2. Vacuum relief valve

3. Gasket

Fig. 4-2- 10

Fuel filler cap cross-section

REMOVAL AND INSTALLATION

CALJTION:

Before attempting. service of any type on

fuel system, the following cautions should

be always observed.

l

Disconnect negative cable at battery.

l

DO NOT smoke, and place “NO

SMOK-

I NG” signs near work area.

l Be sure to have

COZ

fire extinguisher

handy.

0

Wear safety glasses.

l To release fuel vapor pressure in fuel

tank, remove fuel filler cap from fuel

filler neck and then reinstall it. If

prec

sure in fuel tank is not released before-

hand, fuel in fuel tank may come out of

fuel hoses due to the pressure when they

are disconnected.

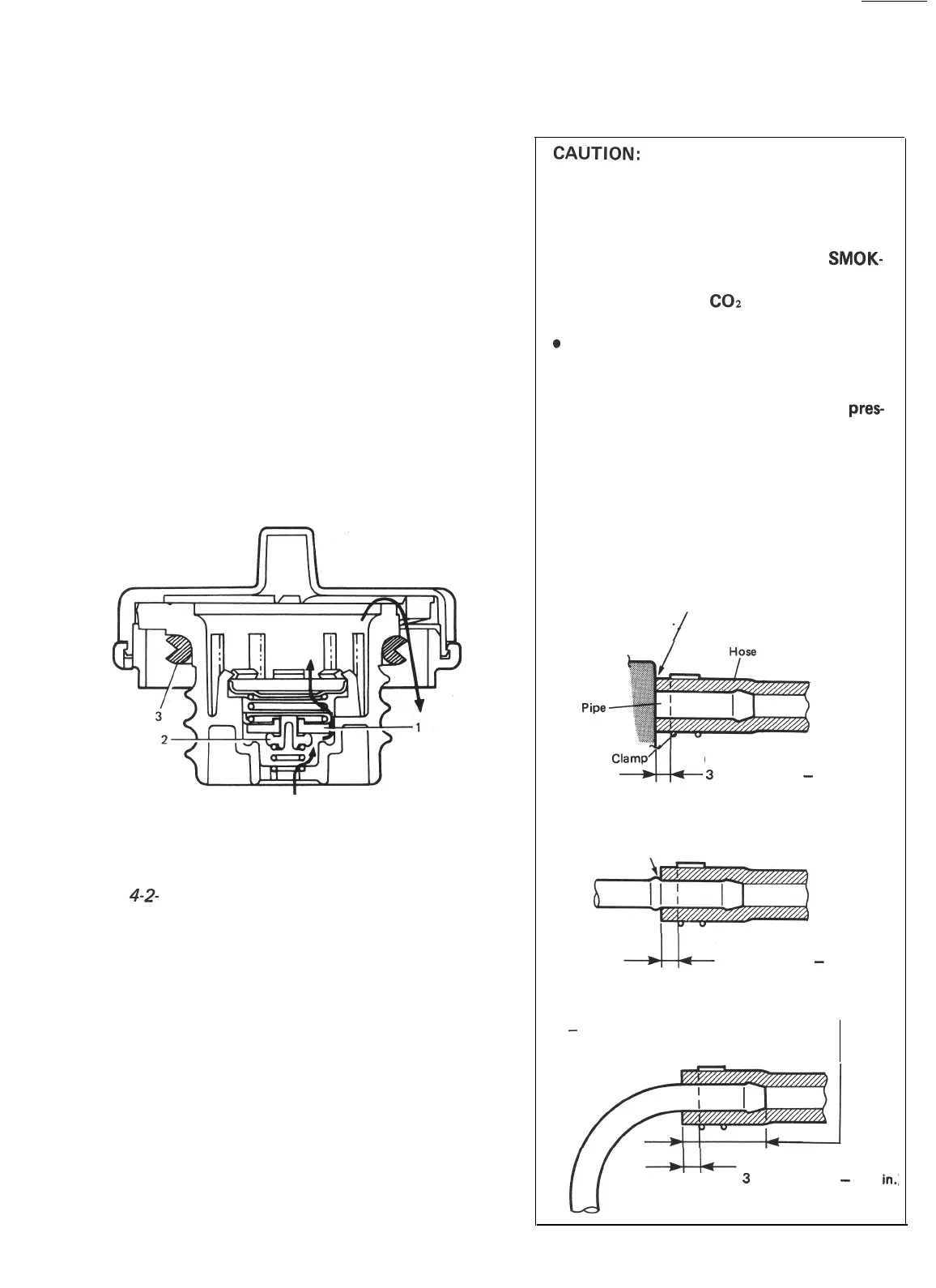

l Note that fuel hose connection varies

with each type of pipe. Be sure to

connect and clamp each hose correctly

referring to the following.

With following type pipe, fit hose as far as it reaches

pipe joint as shown.

/

Clamp securely at a position

3

to 7 mm (0.12

-

0.27 in.)

from hose end.

With following type pipe, fit hose as far as its peri-

pheral projection as shown.

\

Clamp securely at a position

3 to 7 mm (0.12

-

0.27 in.)

from hose end.

With following type pipe, fit hose es far as its bent

part as shown or till pipe is about 20 to 30 mm (0.79

-

1.18 in.) into the hose.

Clamp securely at a positior

3

to 7 mm (0.12

-

0.27

in.:

from hose end.

4-33

Loading...

Loading...