[Hoses]

Visually inspect hoses and pipe for cracks,

damage, or excessive bends, and hose connec-

tion for tightness.

Fig. 5-3-9

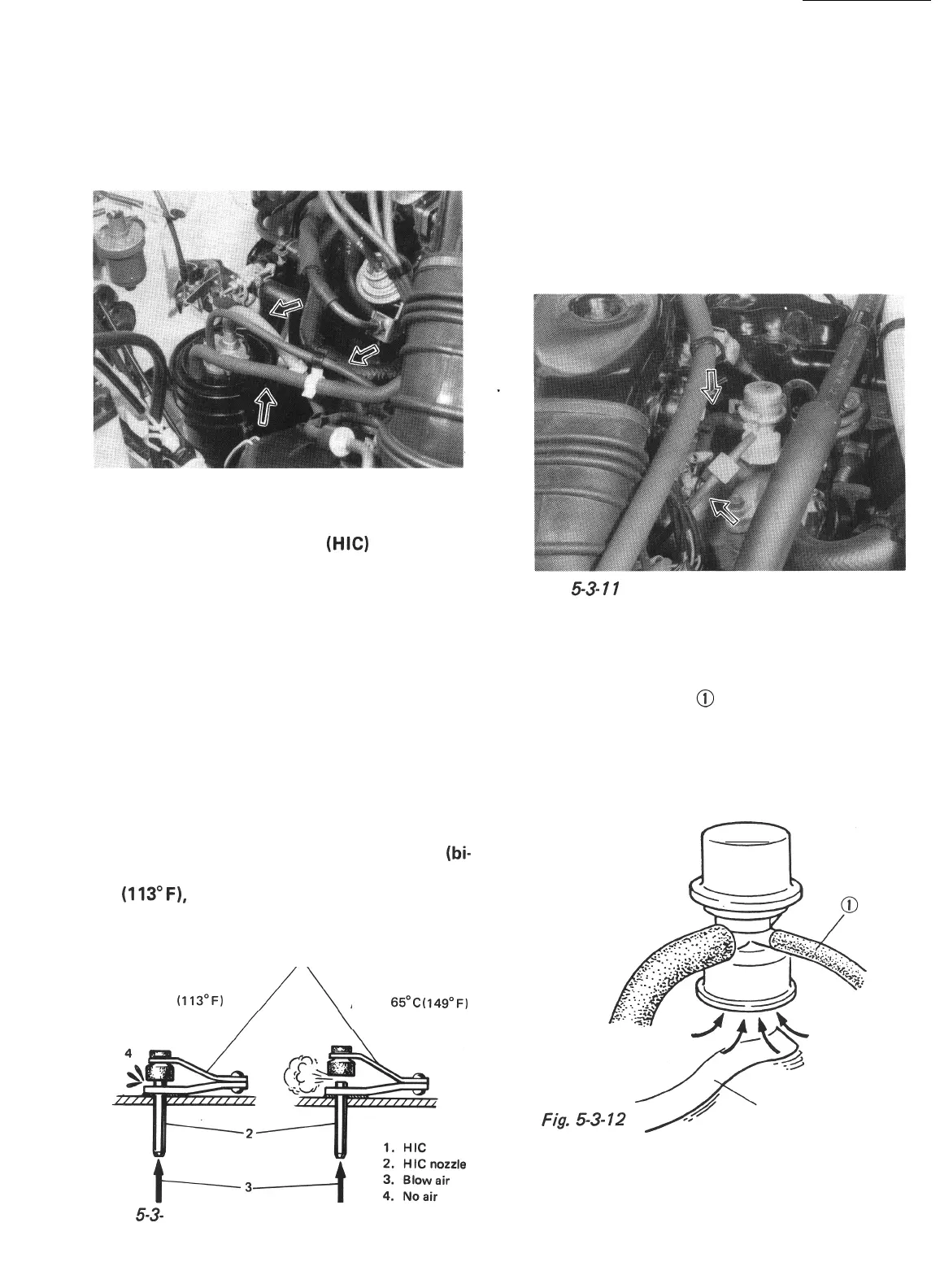

HOT IDLE COMPENSATOR (HIC)

Checking Hot Idle Compensator

1) Remove air intake case with hose.

2) Check temperature around HIC with thermo-

meter.

3) If temperature is below 45°C (113” F), air

should not come out of HIC when air is

blown into hose. If temperature is above

65°C (149” F), air comes out of HIC.

Replace H IC if defective.

4) After checking, install air intake case and

connect hose to intake manifold.

NOTE:

l To check HIC for operation at higher than

65°C (149°F) temperature when HIC

(bi-

metal) temperature is lower than 45°C

(113”F), warm it up with hair drier or photo

light before checking.

l

Never touch bimetal or valve in HIC.

1

Below 45°C

(113’F)

Above

65’C

(149’F)

Fig.

5-i-

10

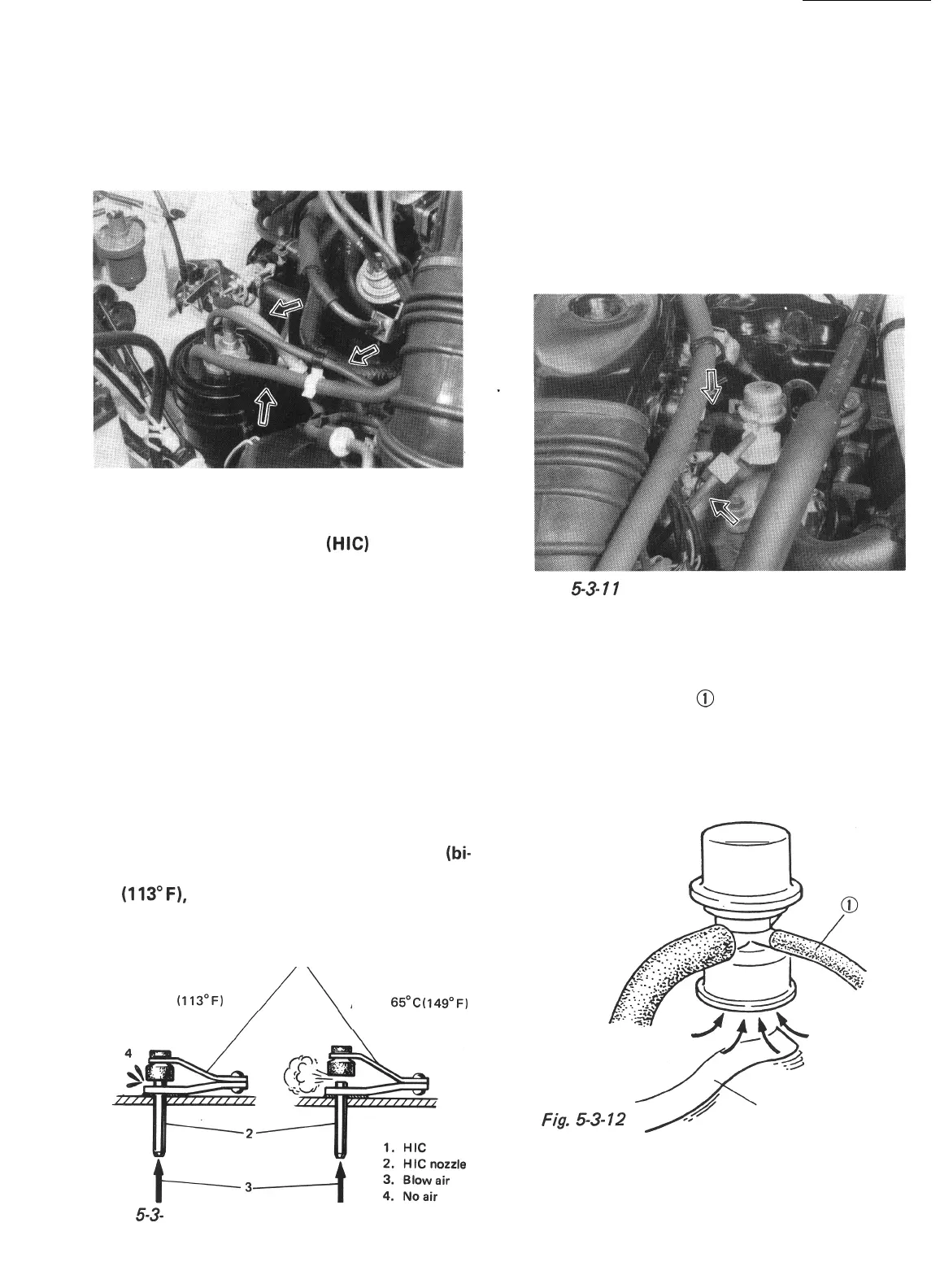

DECELERATION MIXTURE CONTROL

SYSTEM

Checking

[Hoses]

Inspect each hose for pinholes, cracks or damage.

Also check to ensure that each joint is securely

connected. Any part found defective must be

corrected or replaced.

.

Fig.

5-3-

11

[Mixture control valve (MCV)]

1) Warm up the engine to normal operating

temperature.

2) Disconnect hose

@

and reconnect it. At this

time, check that air is drawn into MCV.

NOTE:

At this time, the engine will idle rough or die,

but this is normal.

A piece of paper

If the above checks show anything wrong,

replace it.

5-21

Loading...

Loading...