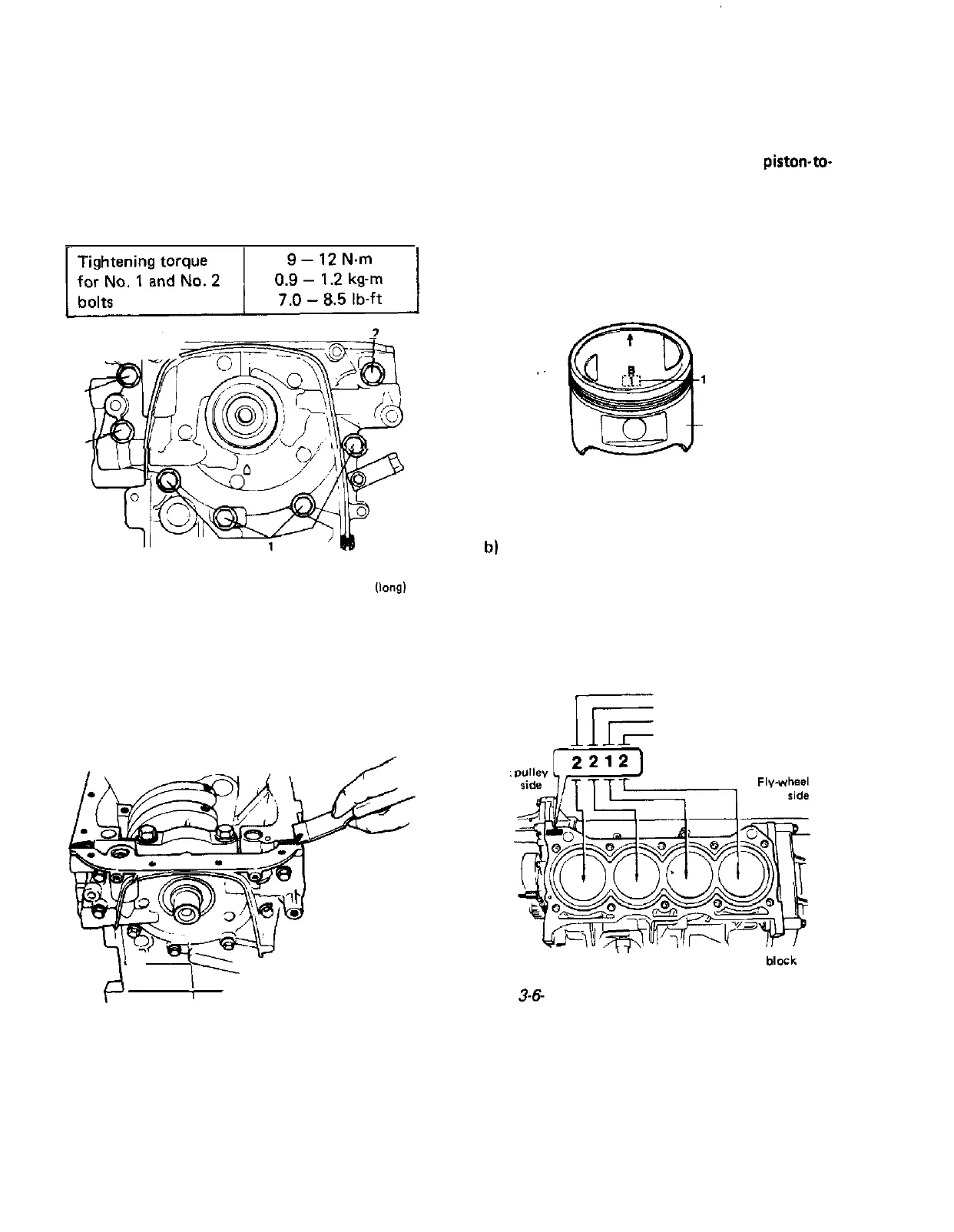

3) Install oil pump to crankshaft and cylinder

block. install No. 1 and No. 2 bolts as shown

in Fig. 3-6-7, and tighten them to specified

torque.

After installing oil pump, check to be sure

that oil seal lip is not upturned, and then

remove special tool.

-

2

2

Fig. 3-6-7

1. NO. 1 bolts (short)

2. No. 2 bolts

(long)

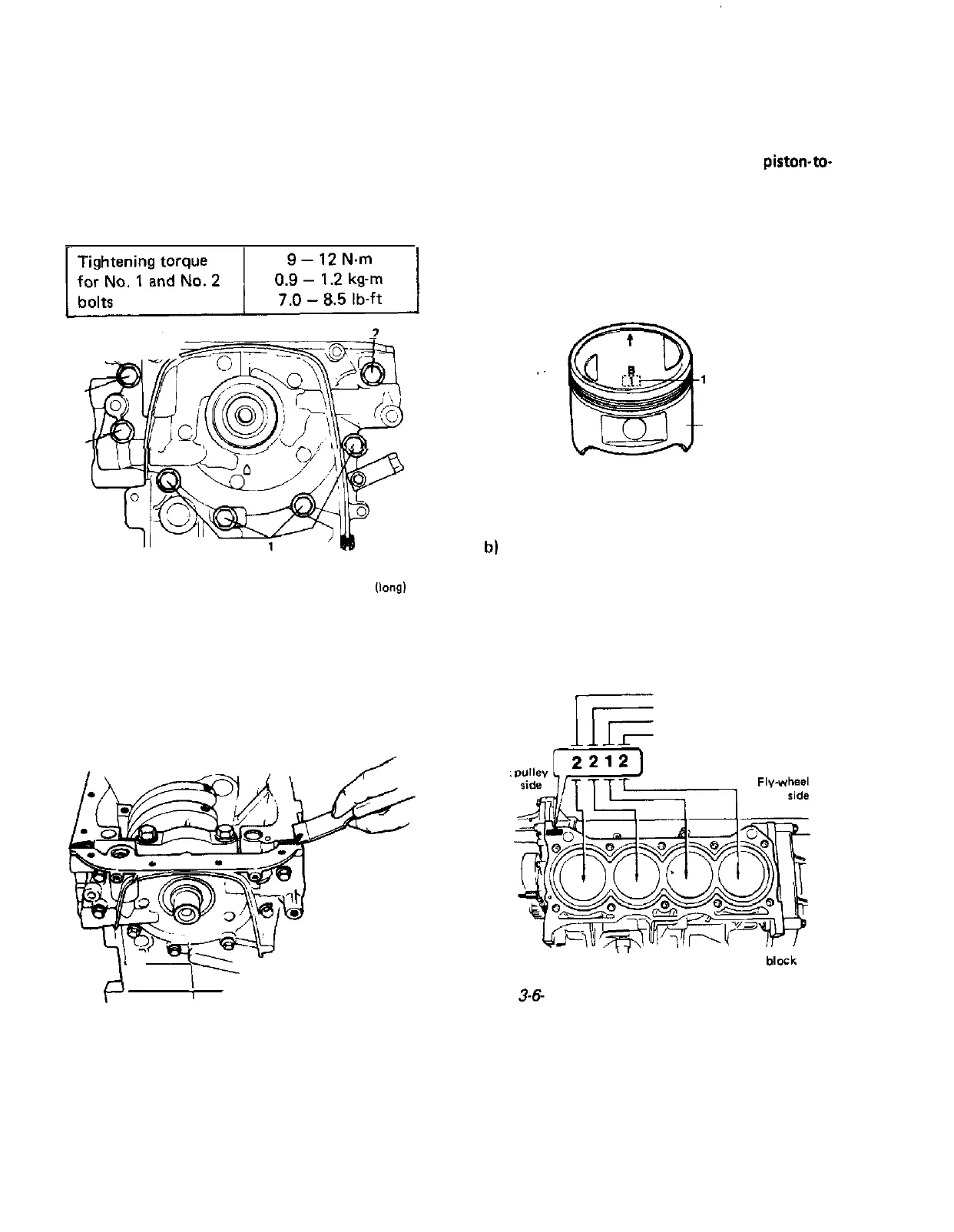

Piston, Connecting Rod and Piston Rings

NOTE:

Two sizes of piston are available as standard size

spare part so as to ensure proper

piston-to-

cylinder clearance. When installing a standard

size piston, make sure to match piston with

cylinder as follows.

a) Each piston has a stamped number 1 or 2 as

shown depending on its outer diameter.

or 2

Piston

Fig. 3-6-9

b)

There are also stamped numbers of 1 and 2

on cylinder block as shown below. First

number indicates inner diameter of No. 1

cylinder, second number of No. 2 cylinder,

third number of No. 3 cylinder and fourth

number of No. 4 cylinder.

4) Edge of oil pump gasket might bulge out: if

it does, cut bulge off with a sharp knife,

making edge smooth and flush with end

faces of the pump case and cylinder block.

Crank

No. 1 Cylinder

No. 2 Cylinder

No. 3 Cylinder

No. 4 Cylinder

Cylinder block

Fig.

3-6-

10

Fig. 3-6-8 Cutting the edge of gaske t

3-38

Loading...

Loading...