THROTTLE VALVE

INDICATOR

POSITION

MOVEMENT

Idle position

Swing

l/2

open

Stay after deflection

Full open

Swing

NOTE:

If indicator doesn’t deflect at all, reverse above

connection, that is, negative prod to body and

positive one to check terminal, and carry out the

same check.

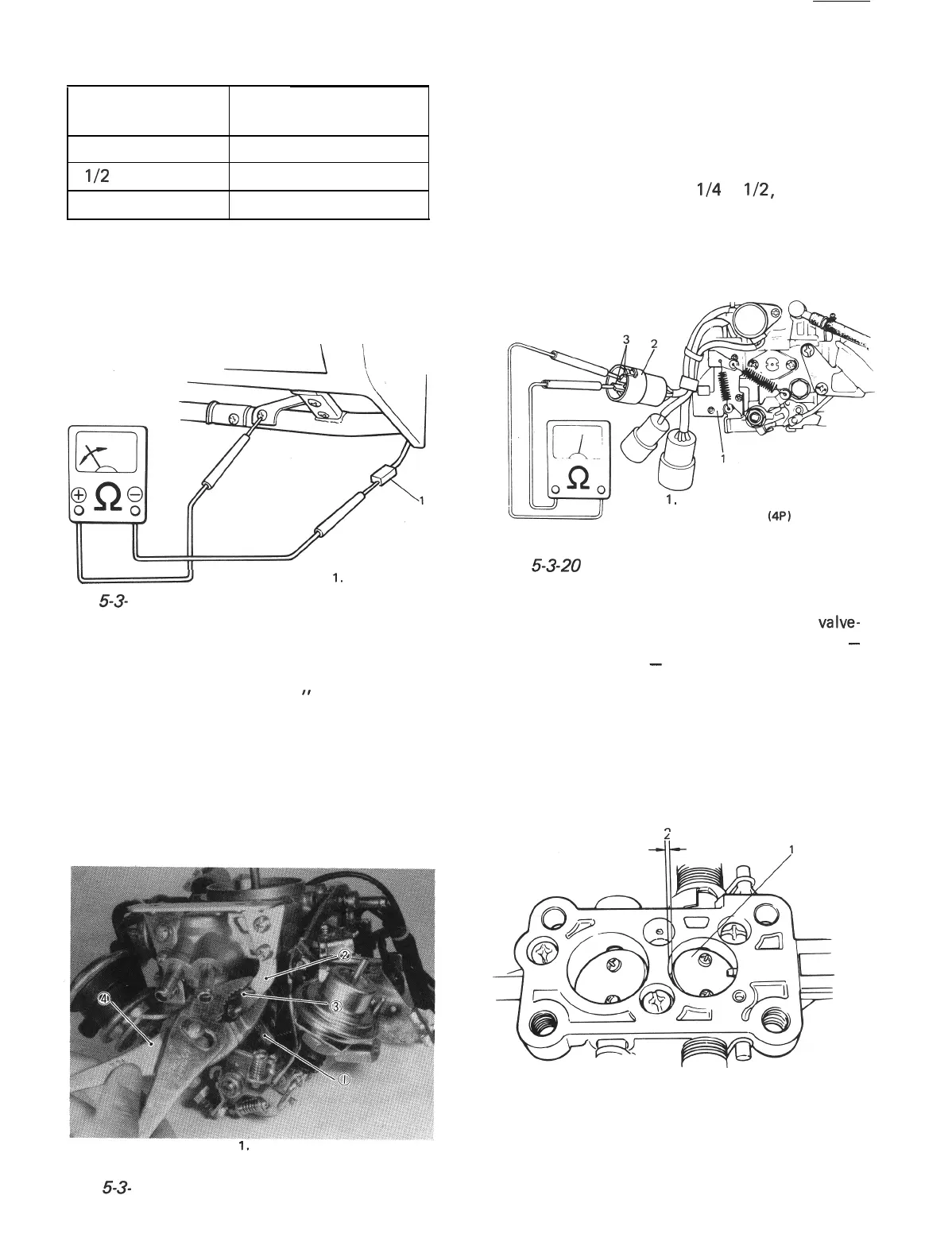

Fig.

53-

18

1.

Check terminal

If check results are not satisfactory, check idle

and wide open micro switches as follows or their

circuits for continuity referring to item “check-

ing sensors and their lead wires

”

(p. 5-32).

[Idle micro switch]

1) Remove carburetor following normal service

procedures.

2) Turn fast idle cam counterclockwise and

insert a suitable pin available then into

holes in cam and bracket to lock the cam.

1,

Fast idle cam

3. Pin

2. Bracket

4. Plier

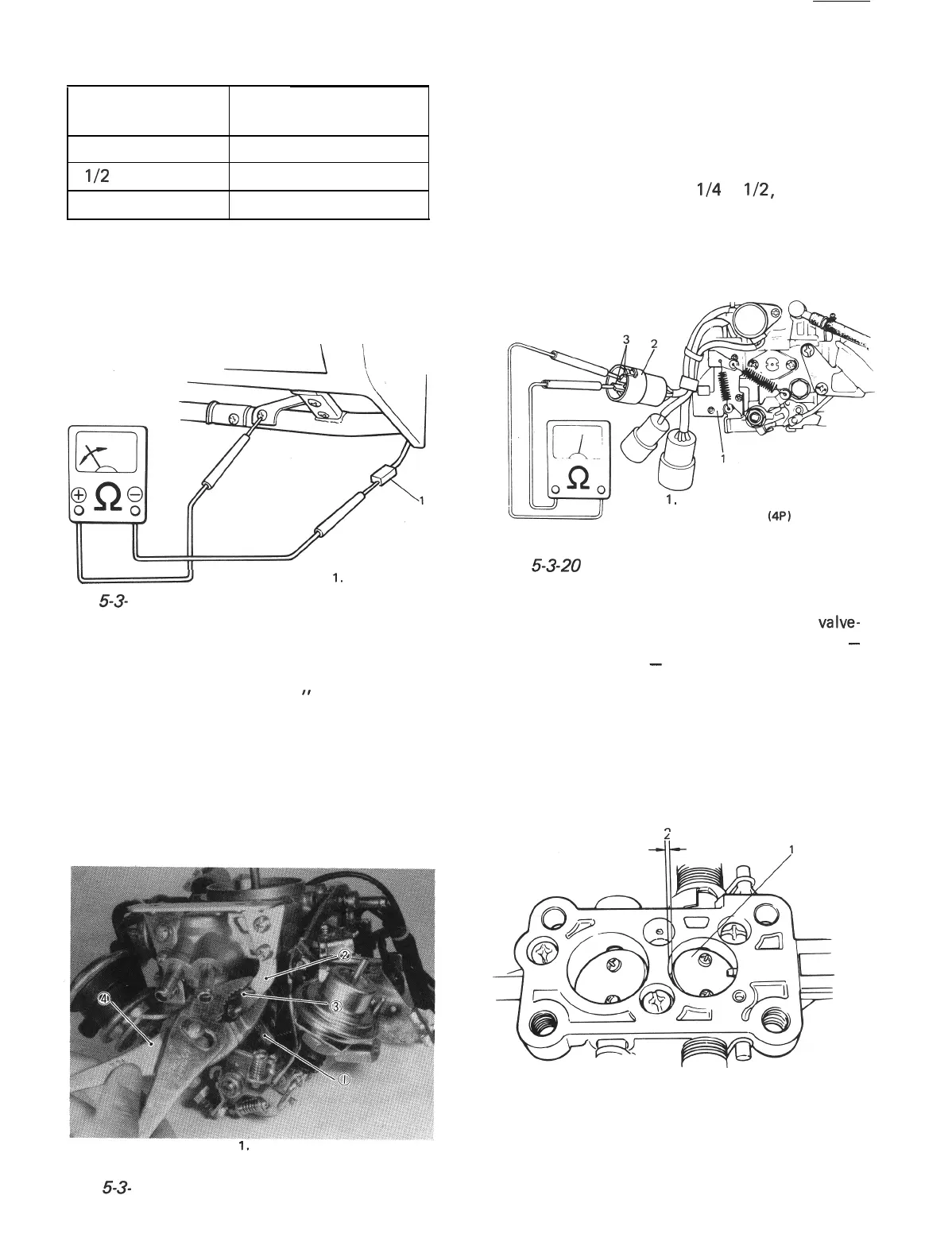

3) Connect ohmmeter to terminals of idle micro

switch. Check for continuity between termi-

nals. When throttle valve is at idle position,

ohmmeter should indicated “zero” ohm.

4) Open throttle valve by

l/4

to

l/2,

and ohm-

meter indicator should indicate infinity.

If check results in steps 3) and 4) are not

satisfactory, replace idle micro switch with a

new one.

1.

idle micro switch

2. Green coupler (4P)

3. idle micro switch’s terminals

(Green/White and Black wires)

Fig. 5-3-20 Connecting ohmmeter to idle micro

switch

5) Open throttle valve slowly till throttle

valve-

to-carburetor bore clearance becomes 0.36

-

0.62 mm (0.014

-

0.024 in) and check that

ohmmeter indicator moves from “zero” ohm

to infinity then.

If the above indicator movement does not

occur within specified range, make adjust-

ment by bending lever shown in below figure.

Bend lever down when clearance is below

specification and up when over specification.

n

1. Primary throttle valve

2. Clearance

Fig. 5-3-21 Clearance between throttle valve

and carburetor bore

Fig. 5-3- 19

5-24 4

Loading...

Loading...