ASSEMBLY

PRECAUTION OF INSTALLATION

NOTE:

NOTE:

Before assembling, wash each part in fluid

See NOTE at the beginning of this section.

recommended to use for the car.

Adjust clearance between booster

piston

rod

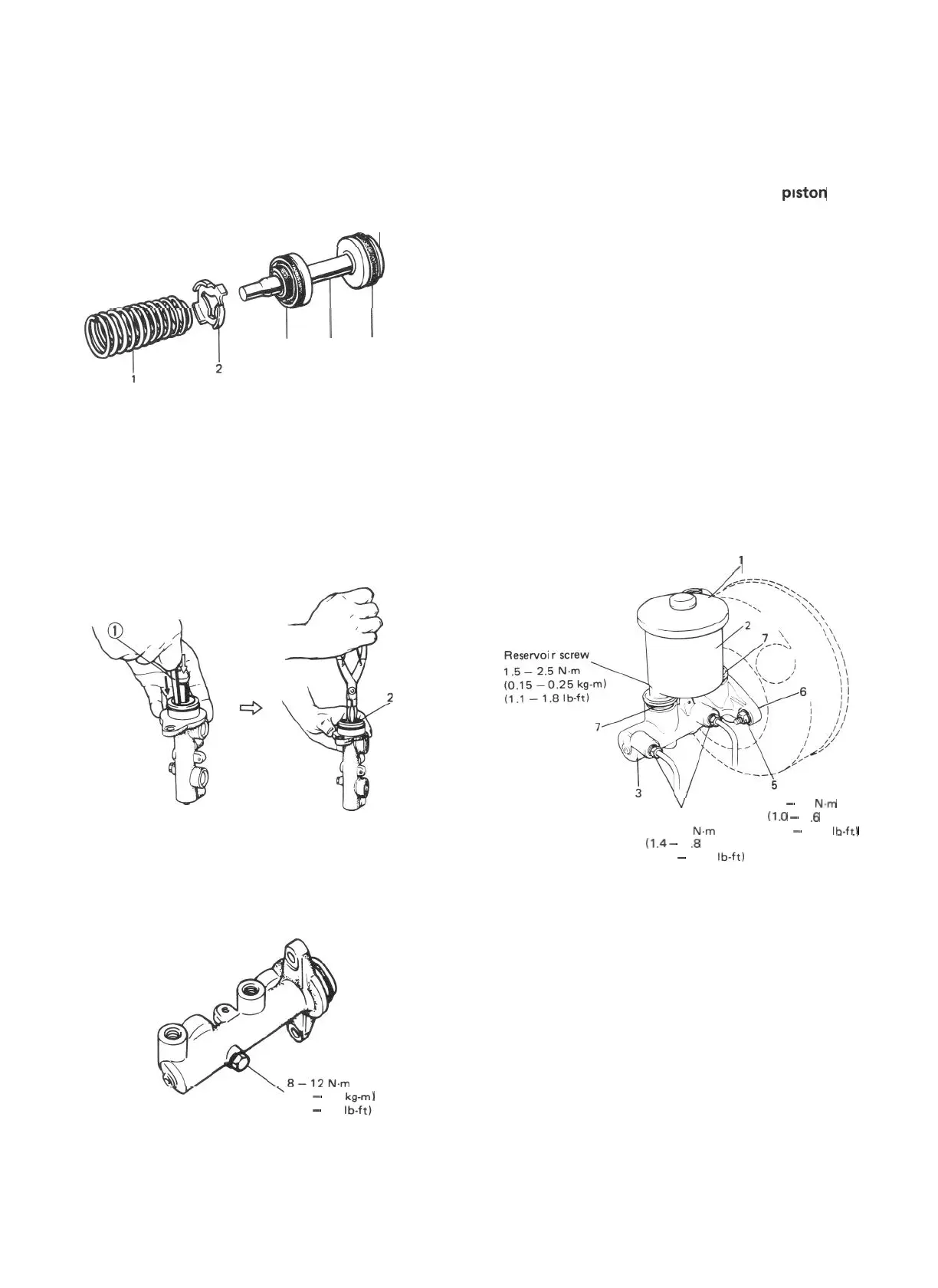

1) Assemble secondary piston as shown below.

FBh

and primary piston with special tool (See page

19-33).

Fig. 19-61

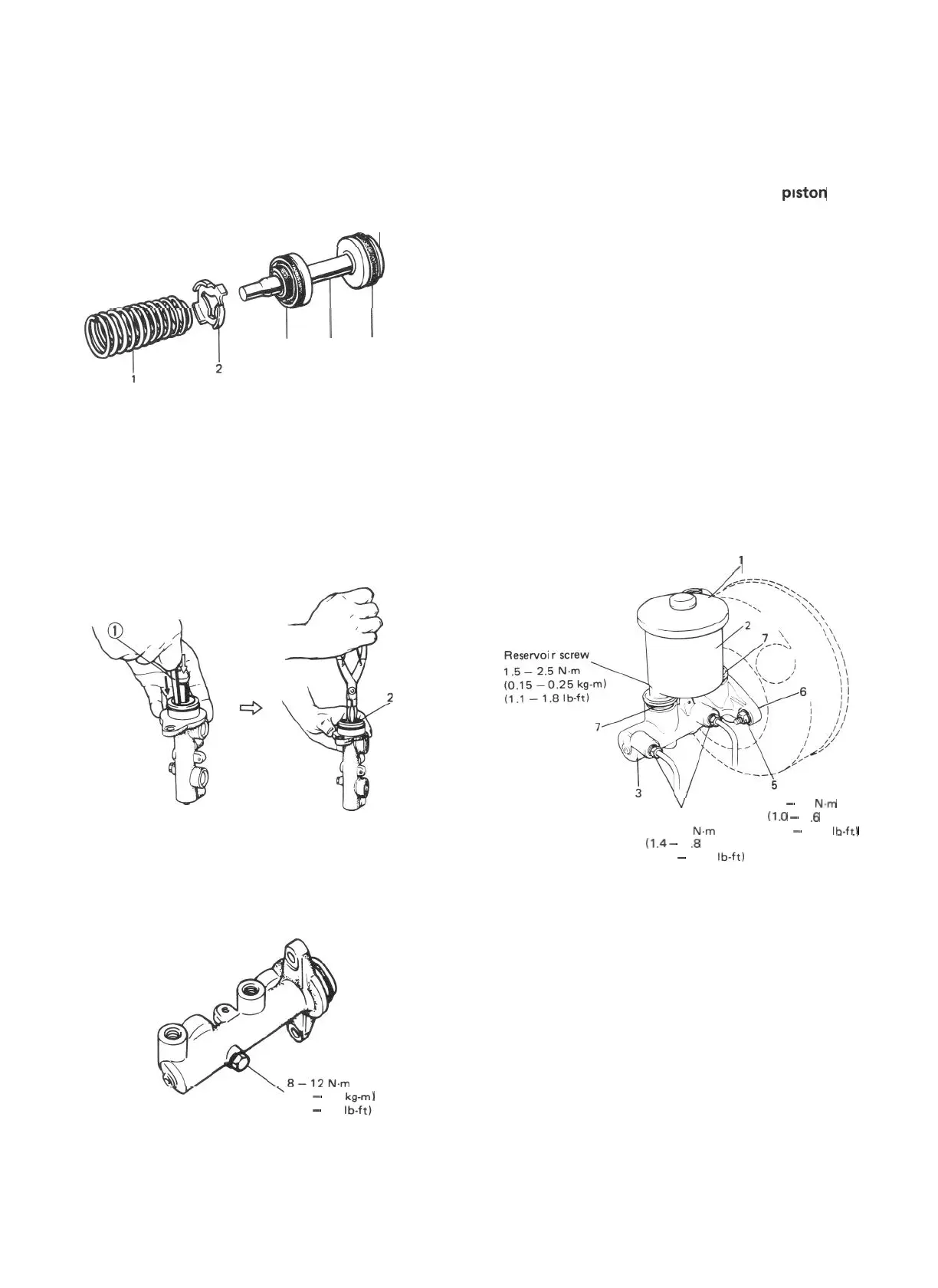

1) Install master cylinder as shown and torque

attaching nuts to specification.

2) Connect 2 hydraulic lines and torque flare

1.

2.

3.

4.

5.

I

I

3

4

5

Secondary piston return spring

Return spring seat

Piston cup

Secondary piston

Piston pressure cap

2) Install secondary piston assembly into cylin-

der.

3) Install primary piston in cylinder.

4) Depress, and install circlip.

nuts to specification.

3) When using new grommets, lubricate them

with the same fluid as the one to fill reser-

voir with. Then press-fit grommets to master

cylinder. Grommets must be seated in place.

4) Install reservoir and tighten screw to specified

torque.

5) Fill reservoir with specified fluid.

After installing, check brake pedal height,

bleed air from system (See p. 19-43 and

p. 19-46) and also check for fluid leakage.

:

Fig. 19-62

2. Circlip

1. Rod

5) Install piston stopper bolt with pistons pushed

in all the way and tighten it to specified

torque.

(0.8

-

1.2

kam)

1. Reservoir

10

-

16 N.m

cap

4

2.

Reservoir

(1

.O

-

1

.6

kg-m)

14-18 N.m

(7.5

-

11.5

lb-ftl

-

-I

3. Master cylinder

(1

.4

-

1

.8

kg-m)

4. Flare nuts

(10.5

-

13.0 lb-ft)

5. Attaching nuts

6.

Gasket

7. Grommets

Fig. 19-64

Fig. 19-63

(6.0

-

8.5 lb-ft).

6) For installation on car, refer to INSTALLA-

TION.

19-29

Loading...

Loading...